Elan Windshield Trim

4 posts

• Page 1 of 1

I am restoring a 1967 Elan S3 convertible and there are several areas in which I could use some help. One of these areas is the two aluminum drip rails that run down either side of the windshield frame - Part numbers 500 B 0309 (LH), and 500 B 0310 (RH) measuring about 14? long X 1? wide and held in place with 4 each self tapping screws. My question is, should I apply a sealant between the drip rail and the windshield frame, and if so, where and how much do I apply?

Another question is in the same area and a little more difficult to describe. The aluminum retaining strip, part number 500 B 0319, measuring about 42? long X 1?? wide, is attached to the top of the windshield frame using 16 each, 1/8? pop rivets. The problem is there is a larger hole (.225? dia.) in the middle of the 42?? long retaining strip. The hole lines up right in the middle of the bolt that holds the torsion rod in place. The question is two fold. First, does the retaining strip set on top on the bolt head to support the metal strip, or does the bolt go through the hole? I can?t find any pictures or information about this area and I can?t remember how it came apart. Secondly, is sealant used between the windshield frame and the retaining strip, and if so, how much?

Any help or guidance anyone could provide would be highly appreciated indeed.

Steve

Another question is in the same area and a little more difficult to describe. The aluminum retaining strip, part number 500 B 0319, measuring about 42? long X 1?? wide, is attached to the top of the windshield frame using 16 each, 1/8? pop rivets. The problem is there is a larger hole (.225? dia.) in the middle of the 42?? long retaining strip. The hole lines up right in the middle of the bolt that holds the torsion rod in place. The question is two fold. First, does the retaining strip set on top on the bolt head to support the metal strip, or does the bolt go through the hole? I can?t find any pictures or information about this area and I can?t remember how it came apart. Secondly, is sealant used between the windshield frame and the retaining strip, and if so, how much?

Any help or guidance anyone could provide would be highly appreciated indeed.

Steve

- woody44

- New-tral

- Posts: 3

- Joined: 13 Jun 2007

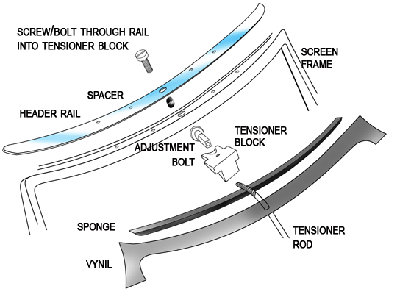

This is how I did it..... it may not be the correct or the best way, but it's how mine came apart.

I had a slot head bolt through the header rail and a rusty thick washer as a spacer between the rail and the fibreglass, the hood used to blow off at speed because the rivets were loose and the spacer gap too big - I used to wedge coins in between the hood and the rail!

When rebuilding, I didn't put any silicone between the rail and fibreglass to ensure a tight fit, although i don't see why you couldn't. I've changed the rusty washer for an aluminium one. The foam/sponge was half a household central heating pipe wrap (an excellent idea suggested elswhere), glued the vynil at the front (engine side) first - lots of pegs, rivetted, bolted up, then next day glued at the back - after the front had dried. - remember that the screen rubber has to fit over this vynil as well (I didn't, so did it twice!) and door trim has to fit over rear part so make sure foam/sponge is central. Tensioner rod is not to be taut but can be fine adjusted after all glued together and screen in coz has squared end

I took these pics and drew the diagram before I took it apart. Good luck and remember: measure twice cut once.

As for the drip rails either side of the screen, on taking apart, yes they had goo underneath and Brian Bucklands book says yes apply silicone top to bottom in line with screws.

I had a slot head bolt through the header rail and a rusty thick washer as a spacer between the rail and the fibreglass, the hood used to blow off at speed because the rivets were loose and the spacer gap too big - I used to wedge coins in between the hood and the rail!

When rebuilding, I didn't put any silicone between the rail and fibreglass to ensure a tight fit, although i don't see why you couldn't. I've changed the rusty washer for an aluminium one. The foam/sponge was half a household central heating pipe wrap (an excellent idea suggested elswhere), glued the vynil at the front (engine side) first - lots of pegs, rivetted, bolted up, then next day glued at the back - after the front had dried. - remember that the screen rubber has to fit over this vynil as well (I didn't, so did it twice!) and door trim has to fit over rear part so make sure foam/sponge is central. Tensioner rod is not to be taut but can be fine adjusted after all glued together and screen in coz has squared end

I took these pics and drew the diagram before I took it apart. Good luck and remember: measure twice cut once.

As for the drip rails either side of the screen, on taking apart, yes they had goo underneath and Brian Bucklands book says yes apply silicone top to bottom in line with screws.

-

SADLOTUS - Fourth Gear

- Posts: 517

- Joined: 19 Oct 2003

SADLOTUS wrote:Brian Bucklands book says yes apply silicone top to bottom in line with screws.

FWIW I'd stick to using silicone in the bathroom and use either proper rubberised automotive seam sealer or if you want extra strength polyurethane sealer such as Tiger Seal or Sikaflex but the latter would make it more difficult to take apart if you ever need to

Otherwise a perfect answer

As SadLotus has hinted, you need to aim to get a nice uniform and fairly tight gap between the screen top rail and the aluminium strip otherwise the hood will pull out at speed.

John

No longer active on here, I value my privacy.

No longer active on here, I value my privacy.

-

nebogipfel - Coveted Fifth Gear

- Posts: 1275

- Joined: 25 Sep 2003

Gents, thanks eversomuch for the speedy replies.

I wondered what that bracket was for - resting on my dash - silly me!

Things are going together now, I checked the BB book, but it doesn't cover the Drop Head windscreen detail too much, Brian must of had a Coupe, me thinks!

I'm converting the fixing system for the Aluminium rail, using Rivnuts and Countersunk S/Steel 3mm bolts, so that if the gap is wrong, I can adjust it slightly easier than with poprivets alone. Alex Black gave me the idea.

The only slightly confusing detail is that the new hood hasn't got a gap in the centre of the flap, the part that is trapped under the rail, so, try as I may, I can't seem to get the seam fully under the rail? Is there normally a slight gap in the centre of the Black Ambler return flap that gets trapped under the rail - to miss the centre tie rail fixing bolt then?

Must check my old hood in the Morning!

I've engineered the gap to be about 2.5mm, but it's quite cold here at present, and the hood material is quite stiff and a struggle to get in place?

What's the technique in getting the hood under the rail - are there any special tricks?

Does anybody else have a gap in the centre of the hood flap, and does it affect the stability of the hood fixing?

Thanks for all the help,

Philip.

I wondered what that bracket was for - resting on my dash - silly me!

Things are going together now, I checked the BB book, but it doesn't cover the Drop Head windscreen detail too much, Brian must of had a Coupe, me thinks!

I'm converting the fixing system for the Aluminium rail, using Rivnuts and Countersunk S/Steel 3mm bolts, so that if the gap is wrong, I can adjust it slightly easier than with poprivets alone. Alex Black gave me the idea.

The only slightly confusing detail is that the new hood hasn't got a gap in the centre of the flap, the part that is trapped under the rail, so, try as I may, I can't seem to get the seam fully under the rail? Is there normally a slight gap in the centre of the Black Ambler return flap that gets trapped under the rail - to miss the centre tie rail fixing bolt then?

Must check my old hood in the Morning!

I've engineered the gap to be about 2.5mm, but it's quite cold here at present, and the hood material is quite stiff and a struggle to get in place?

What's the technique in getting the hood under the rail - are there any special tricks?

Does anybody else have a gap in the centre of the hood flap, and does it affect the stability of the hood fixing?

Thanks for all the help,

Philip.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

4 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 11 guests