Sows Ear Chassis

Not a bad day today, about 75 degrees and a good day for painting. I guess last Saturday I didn?t think I would have color on the chassis but sometimes things work out. Great weather helps and I am in between things on the other two project, so this 3rd chassis has gotten a lot of attention this week. I used about 280 lbs of black beauty to blast it so I still have a 100 lb. Bag plus a bit to do suspension parts. I also saved another 100 lbs. of used blast material that will need to be sifted to get out the trash, I hope not to use it but its better than $25 a bag and driving 40 miles to get it if I run low. The weather for tomorrow is supposed to be good so I hope to get some other parts blasted and maybe painted too, I?ll have to see how things go.

The brake lines were cleaned last Saturday and everything looked good so on they went.

Sunday May 20rh 04:40 pm

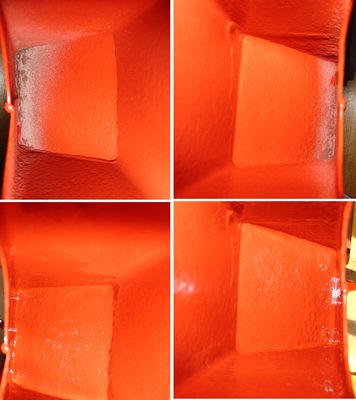

I got something done today. I started by looking at the bottoms of the turrets, these are just a bitch and I don't know a good way to get them 100% clean before painting, I must have used 20 lbs of black beauty trying to get the very bottom clean. In the end there was a bit of color there and it will bight me if I live long enough but after 47 years, to get another 15 seems like and easy thing as it will likely see about the same use as it did in its first 4 on the streets of Boston, Cambridge, and other Eastern Massachusetts towns. I ended up cutting a 1 inch wide paint brush to get in and paint the bottoms as the spray gun just didn't do it at the angle I was spraying from. The more I do, the more I think about the different angles needed to completely cover a chassis. There are just a lot of hard to shoot areas that you need to deal with, just as there is when sand blasting. It would probably be worth it to try one of the ready strip chemical dip places if you had a pristine original chassis that you were working with.

There was not enough time to get them painted but maybe tomorrow. some of them need a bit more prep work but still a pretty good day even if it doesn't look like much.

Wednesday May 23rd 06:25 am

Not a lot happening this week, just rain and fog so limited outdoor activity and that about kills any progress. I got the fuel line and e-brake cable installed but thats about all. Diff cases went to my friend Karl's yesterday to be welded. I think I'll take some brake calipers and turn them into smaller pieces today and see just how much money I need to dump into them.

Wednesday May 23rd 10:35 am

I just wanted to get something done this morning and I guess that meant more disassembly. Rear calipers looked to be "easy", they have probably never been apart but had new pads so they were touched at some point probably just before the S2 was parked back in 1969. Thats seems like a long time ago to me, I was not even driving but having fun on a bicycle. Anyway I thought that with the pistons fully enclosed with cast iron that they would just pop out with a bit of air pressure. The compressor has been running at about 100 psi for a while, I hooked up the rig to put some air into the first rear caliper at about 7:30 and one piston started to move. I next pulled out the pads and got a clamp on the one that moved. hooked the adapter rig to put some air pressure behind the pistons and waited a few seconds, Nothing. I started to hit the back side of the cast iron to just give it a bit of shock, still no movement. I figured 50% was an ok start but it was time to get serious. I got a flat blade screwdriver and made a adjustment to the pressure regulator on the compressor, I used to run it at 180 max when I had it in the old shop so I gave the screw a few turns and it kicked it up to 170 psi. I tried again and the same results, nothing. I decided on trying the other caliper and it liked the added pressure and one piston moved so I disconnected the rig and applied the clamp on that piston and reconnected the rig. not much so I gave the piston a couple of wraps with the copper pipe and it popped out. so I was 3 for 4 and feeling like things were going to work out just fine. Back to the first caliper with the clamp on the piston that moved and got a punch out, it was clear that the pistons were junk and I could have my brutal way with them. It took a couple of minutes with full air pressure and a freshly sharpened center punch with me hitting the stuck caliper piston so it would start to rotate in the bore but when it did it popped right out and hit the clamp on the opposite side. SUCCESS! 4 for 4 and now its time to finish cleaning up these beauties...

The brake lines were cleaned last Saturday and everything looked good so on they went.

Sunday May 20rh 04:40 pm

I got something done today. I started by looking at the bottoms of the turrets, these are just a bitch and I don't know a good way to get them 100% clean before painting, I must have used 20 lbs of black beauty trying to get the very bottom clean. In the end there was a bit of color there and it will bight me if I live long enough but after 47 years, to get another 15 seems like and easy thing as it will likely see about the same use as it did in its first 4 on the streets of Boston, Cambridge, and other Eastern Massachusetts towns. I ended up cutting a 1 inch wide paint brush to get in and paint the bottoms as the spray gun just didn't do it at the angle I was spraying from. The more I do, the more I think about the different angles needed to completely cover a chassis. There are just a lot of hard to shoot areas that you need to deal with, just as there is when sand blasting. It would probably be worth it to try one of the ready strip chemical dip places if you had a pristine original chassis that you were working with.

There was not enough time to get them painted but maybe tomorrow. some of them need a bit more prep work but still a pretty good day even if it doesn't look like much.

Wednesday May 23rd 06:25 am

Not a lot happening this week, just rain and fog so limited outdoor activity and that about kills any progress. I got the fuel line and e-brake cable installed but thats about all. Diff cases went to my friend Karl's yesterday to be welded. I think I'll take some brake calipers and turn them into smaller pieces today and see just how much money I need to dump into them.

Wednesday May 23rd 10:35 am

I just wanted to get something done this morning and I guess that meant more disassembly. Rear calipers looked to be "easy", they have probably never been apart but had new pads so they were touched at some point probably just before the S2 was parked back in 1969. Thats seems like a long time ago to me, I was not even driving but having fun on a bicycle. Anyway I thought that with the pistons fully enclosed with cast iron that they would just pop out with a bit of air pressure. The compressor has been running at about 100 psi for a while, I hooked up the rig to put some air into the first rear caliper at about 7:30 and one piston started to move. I next pulled out the pads and got a clamp on the one that moved. hooked the adapter rig to put some air pressure behind the pistons and waited a few seconds, Nothing. I started to hit the back side of the cast iron to just give it a bit of shock, still no movement. I figured 50% was an ok start but it was time to get serious. I got a flat blade screwdriver and made a adjustment to the pressure regulator on the compressor, I used to run it at 180 max when I had it in the old shop so I gave the screw a few turns and it kicked it up to 170 psi. I tried again and the same results, nothing. I decided on trying the other caliper and it liked the added pressure and one piston moved so I disconnected the rig and applied the clamp on that piston and reconnected the rig. not much so I gave the piston a couple of wraps with the copper pipe and it popped out. so I was 3 for 4 and feeling like things were going to work out just fine. Back to the first caliper with the clamp on the piston that moved and got a punch out, it was clear that the pistons were junk and I could have my brutal way with them. It took a couple of minutes with full air pressure and a freshly sharpened center punch with me hitting the stuck caliper piston so it would start to rotate in the bore but when it did it popped right out and hit the clamp on the opposite side. SUCCESS! 4 for 4 and now its time to finish cleaning up these beauties...

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

It cleared up so I got a bit of blasting in and it still looked good so out came the spray gun. Lot of stuff covered and I think it may be nearing the end of the wholesale rust slaughter for a while.

I also taped off the mating surfaces so they are still clean. When the halves are joined I'll touch up the seam with a bit of paint.

Some parts were dry so best to get them off the floor and where they belong. hope to get the uprights on later. I don't have shocks so that part is on hold for a while.

Friday May 25th 1:10 pm

More parts blasted and painted, The only thing harder to paint well is is to sand blast springs well, just a lot of angles to get everything from. I am never sure it's good enough but after a hour or so for a couple of springs it time to get on with it.

Saturday May 26th 1:30 pm

Not a lot happening today so I decided to get another box painted. I liked the last one I did with the 10% black added to the hunter green but thought it could be a bit darker so this one got 20% semi-gloss black and may be too dark but when I looked at the mix at 15%, it looked like it needed more black so I gave it more,

I also taped off the mating surfaces so they are still clean. When the halves are joined I'll touch up the seam with a bit of paint.

Some parts were dry so best to get them off the floor and where they belong. hope to get the uprights on later. I don't have shocks so that part is on hold for a while.

Friday May 25th 1:10 pm

More parts blasted and painted, The only thing harder to paint well is is to sand blast springs well, just a lot of angles to get everything from. I am never sure it's good enough but after a hour or so for a couple of springs it time to get on with it.

Saturday May 26th 1:30 pm

Not a lot happening today so I decided to get another box painted. I liked the last one I did with the 10% black added to the hunter green but thought it could be a bit darker so this one got 20% semi-gloss black and may be too dark but when I looked at the mix at 15%, it looked like it needed more black so I gave it more,

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Another slow morning. I got a photo of the gearbox line up with thedifferent shades of Hunter green, not any look like the original but that happens when it not all that important to me, I think the two with some black look good and I guess that the 100% hunter green is ok too. It will be mostly out of site most all of the time so I can't get all worked up over it.

For years on this forum I keep reading about getting the slave cylinder so that the bleeder port is the highest point. To be honest I can't see how thats possible, Its either on the left or the right unless the Elan is on its side and that seems to be more of a problem to me. Maybe the lip seal closing plates are different?

For years on this forum I keep reading about getting the slave cylinder so that the bleeder port is the highest point. To be honest I can't see how thats possible, Its either on the left or the right unless the Elan is on its side and that seems to be more of a problem to me. Maybe the lip seal closing plates are different?

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Salut Gary

Amazing thread and documenting!

I haven't kept up so I'll have to go back and find out why you paint everything red (and why you changed colour for the 'box).

Thanks for sharing.

@+

Vernon

Amazing thread and documenting!

I haven't kept up so I'll have to go back and find out why you paint everything red (and why you changed colour for the 'box).

Thanks for sharing.

@+

Vernon

-

vernon.taylor - Fourth Gear

- Posts: 683

- Joined: 05 Nov 2010

vernon.taylor wrote:Salut Gary

Amazing thread and documenting!

I haven't kept up so I'll have to go back and find out why you paint everything red (and why you changed colour for the 'box).

Thanks for sharing.

@+

Vernon

What color is the pumpkin/diff painted

elan-f15/what-color-the-pumpkin-diff-painted-t17043.html

More original paint (Components Colours)

elan-f14/more-original-paint-components-colours-and-camera-setup-t23535.html

Hi Vernon

I think Lotus used a lot of "red" when they were built, I am probably not one to adhere to originality but I tried to keep some what on that thought when I started. Some of the parts already had already been painted, so I kept it. I have used a couple of reds, 3 different blacks and hunter green so far with some being mixed with others to either soften or slightly alter what colors I had to work with. If you go back and read this topic from the start the first two chassis are "budget" builds and the 3rd is also a budget build as I am short on available cash to do these. I guess you can spend a lot on a restoration or you can get it done and have something that looks quite nice for very little. These are of the later type and I just wanted folks to be able to see (maybe get motivated) that for some money (not much) and a bit of ones own time (again, not a lot) you can do a good deal of the miserable work and get close to the joys of driving without spending a lot of cash. In approximately 11 weeks since this topic began, I have done (with the help of a few others) nearly 3 chassis builds and if the money was not quite so tight they would be quite a bit further along. I guess so far the cash out of pocket is still under $2k and I cannibalized one past build that didn't get completed due to some issues (like the chassis was not really good enough, broken in the middle, welded - rotted in the turrets, welded - submerged under salt water for a period of 6 hours) but it was the first that I had started 20 years ago. This forum seems to be mostly about talk and I wanted to show what a little time an money can do, I am not there yet but I a few steps closer. The clock keeps ticking and there will come a time when some of what I am doing now is just not possible for me to do and if I don't get on with it someone else will have to clean up this mess I have made and I would really like to avoid that if I can.

Same picture (well close), one without the flash and the other with the flash. They don't look like the same color but there you go!

I got very little done today (Laundry day and I changed the water in Beaus pool, the mosquito larvae were getting big). I did manage to get the original inserts that I was hoping to reuse out, they were too pitted (like the caliper pistons) so they will be replaced. The shocks and donuts are the biggest expense on a chassis rebuild. I am still up in the air about pulling off the hubs, the bearings are good but to paint them, it would be nice to knock them apart. I need to think about this a bit more before I commit to $40 worth of bearings and breaking the taper on the hubs (mostly breaking the taper).

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Hi Gary

Hope you are well.

I really like your posts so keep 'em coming, please. I recently got a bit bogged down in my restoration, mainly because I was having problems with parts availability, parts not fitting or just basically not finding enough time to get on with it. After reading your "Sows Ear Chasssis" posts they made me realise that I just had to get on with the job as best I can and push on through, otherwise like you, someone else would be finishing it for me.

Thank you for the inspiration.

Adam

Hope you are well.

I really like your posts so keep 'em coming, please. I recently got a bit bogged down in my restoration, mainly because I was having problems with parts availability, parts not fitting or just basically not finding enough time to get on with it. After reading your "Sows Ear Chasssis" posts they made me realise that I just had to get on with the job as best I can and push on through, otherwise like you, someone else would be finishing it for me.

Thank you for the inspiration.

Adam

- Pastapesto

- Third Gear

- Posts: 272

- Joined: 12 Nov 2006

I wasn't going to do much today but I got out the press and pushed in one front control arm bush that I had and it went in like it was supposed to and thought although it was foggy I would get a bit more ambitious. I figured I would get the bolt on hubs off the drive axles and maybe get ready so sand blast the upright if it cleared up and everything worked out nicely. The hub nuts came right off the uprights with the impact wrench so I figured I would get on with the worrying off of the hubs with a bit of blunt force trauma to the end of the drive axle. my father gave me a tool nearly 30 years ago that screws onto the 5/8 unf thread and you can give a pretty good wallop to the end of the drive axle without damaging the threads. It works pretty well but I have also ruined a couple of axles over the years by being a bit too forceful. I figured it was worth a try and the first one came right apart with about 3 or 4 good blows with the 48 oz hammer.

Well lets just say the second one didn't just fall off, as a matter of fact I was hitting the bitch as hard as I could and it still didn't ring it hard enough to release the taper. I heated and hit and after about a half an hour nothing had happens. The bearings were still ok and the threads on the end were good too so Beau and I went for a ride to visit Willy. Willy has a 100 pound anvil and I could try a different approach of pinching the hub (without the lugs installed) between the anvil and the 3 (or 4) pound hammer. I tried a couple of good hits once I got the anvil and strut where I had some room to move and rested a bit between beatings. after about 10 minutes it was getting even more clear that today was not going to go all that well so I asked Willy for a bigger hammer, He had one but his son and split the handle, Willy said there was some fiberglass tape so I rigged the handle for a temporary fix and gave the strut as much force as I could without breaking it or anything else around me. Well the 10 pound sledge hammer failed and I loaded the strut and the 2 hammers that I had brought back into the truck and left. By this time the bearing were nfg so it was decision time. I was short on strut Left Hand housings so I needed to save that and the same was also true for the 4 bolt hubs, that meant that the axle was the sacrificial victim as I had two extras that I really didn't want to break the pair at least I had them as extra.

If using the 10 pound sledge is brutal, it was time to go animal on the strut housing and I got out the wiz wheel and cut the ears off of the drive axle and pushed it out with a hammer and chisel. Next week I'll take the hub and cut stub axle and bring up to uncle Carl's where he has a good press and some real heat...

Maybe I should have just painted the strut tubes and hubs in place and called it good, but I don't really think that was an option for me.

Wednesday May30th 11:40

I hate waiting for anything! No one ever called me Patients for a good reason. I didn't want to wait till next week so I figured I would try again. It took only a couple of good hits with the 1/4 inch walled pipe sitting on a big rock and the 4 pound hammer.

At that point I got the sand blaster out and went at it. It started to sprinkle about 2/3 of the way through the first strut, There are a couple of things that I can't do and one is piss into the wind and the other is sand blast in the rain so I took a break and made coffee. It stopped so I finished up. I may get them painted today but it got pretty humid and the pollen is really raining down so I may wait(not likely though) for tomorrow.

Gary

Well lets just say the second one didn't just fall off, as a matter of fact I was hitting the bitch as hard as I could and it still didn't ring it hard enough to release the taper. I heated and hit and after about a half an hour nothing had happens. The bearings were still ok and the threads on the end were good too so Beau and I went for a ride to visit Willy. Willy has a 100 pound anvil and I could try a different approach of pinching the hub (without the lugs installed) between the anvil and the 3 (or 4) pound hammer. I tried a couple of good hits once I got the anvil and strut where I had some room to move and rested a bit between beatings. after about 10 minutes it was getting even more clear that today was not going to go all that well so I asked Willy for a bigger hammer, He had one but his son and split the handle, Willy said there was some fiberglass tape so I rigged the handle for a temporary fix and gave the strut as much force as I could without breaking it or anything else around me. Well the 10 pound sledge hammer failed and I loaded the strut and the 2 hammers that I had brought back into the truck and left. By this time the bearing were nfg so it was decision time. I was short on strut Left Hand housings so I needed to save that and the same was also true for the 4 bolt hubs, that meant that the axle was the sacrificial victim as I had two extras that I really didn't want to break the pair at least I had them as extra.

If using the 10 pound sledge is brutal, it was time to go animal on the strut housing and I got out the wiz wheel and cut the ears off of the drive axle and pushed it out with a hammer and chisel. Next week I'll take the hub and cut stub axle and bring up to uncle Carl's where he has a good press and some real heat...

Maybe I should have just painted the strut tubes and hubs in place and called it good, but I don't really think that was an option for me.

Wednesday May30th 11:40

I hate waiting for anything! No one ever called me Patients for a good reason. I didn't want to wait till next week so I figured I would try again. It took only a couple of good hits with the 1/4 inch walled pipe sitting on a big rock and the 4 pound hammer.

At that point I got the sand blaster out and went at it. It started to sprinkle about 2/3 of the way through the first strut, There are a couple of things that I can't do and one is piss into the wind and the other is sand blast in the rain so I took a break and made coffee. It stopped so I finished up. I may get them painted today but it got pretty humid and the pollen is really raining down so I may wait(not likely though) for tomorrow.

Gary

Last edited by Guest on Wed May 30, 2012 3:39 pm, edited 1 time in total.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Gary,

It looks like that one was fun! Had to get out the big tools to get that apart I see and sure glad you have several spares to choose the new parts from. The last couple times I did this I used a large three or four jaw puller and lots of heat from a gas hatchet. I did not care about the bearings or seals as they got replaced.

I did some digging last night and found a brand new set of Koni struts. Got to see if they are for Elan or +2.

Keep up the good work and the post as it will provide good help to everyone that has not had as much fun as you.

OK I know it is not all fun but still looking great!

Mark

It looks like that one was fun! Had to get out the big tools to get that apart I see and sure glad you have several spares to choose the new parts from. The last couple times I did this I used a large three or four jaw puller and lots of heat from a gas hatchet. I did not care about the bearings or seals as they got replaced.

I did some digging last night and found a brand new set of Koni struts. Got to see if they are for Elan or +2.

Keep up the good work and the post as it will provide good help to everyone that has not had as much fun as you.

OK I know it is not all fun but still looking great!

Mark

-

memini55 - Third Gear

- Posts: 347

- Joined: 09 Jan 2004

why wait  This should have been done yesterday!

This should have been done yesterday!

Thursday Mat 31st 12:45pm

I went to see Steve this morning at South Shore Bearing on Copeland street in Quincy. Beau and I went up in the S2 and Steve's dog greeted us as we pulled up to the door. I guess I have been buying bearings from Steve for nearly 40 years and I have gone elsewhere at times I mostly get what I need there as its and in and out and there is no getting the wrong parts like sometimes happen when you go mail order or worse the dreaded evil bottom of the bay. I left the house about 8am and traffic was near the end of rush hour so the drive up kind of sucked but we were there and I got the 6206 - 2RS bearings (6) and (4) Timkin diff seals (304007) and gave Steve $100 and got $5 back. Not the best deal but it was a "what can I get done this morning" thing and its god damn well done! For the money and time invested new bearing are just a good idea, its the first money I have spent so far on 26/4997 since I started on the chassis other than the black beauty, I had bought a few parts in advance, like top ball joints but not much else. I guess that makes it a bit over $200 so far, I just wish that donuts and shocks weren't so much money. Anyway I got the press out along with the camera and snap ring pliers and a few other needed bits and here is the results.

Thursday Mat 31st 12:45pm

I went to see Steve this morning at South Shore Bearing on Copeland street in Quincy. Beau and I went up in the S2 and Steve's dog greeted us as we pulled up to the door. I guess I have been buying bearings from Steve for nearly 40 years and I have gone elsewhere at times I mostly get what I need there as its and in and out and there is no getting the wrong parts like sometimes happen when you go mail order or worse the dreaded evil bottom of the bay. I left the house about 8am and traffic was near the end of rush hour so the drive up kind of sucked but we were there and I got the 6206 - 2RS bearings (6) and (4) Timkin diff seals (304007) and gave Steve $100 and got $5 back. Not the best deal but it was a "what can I get done this morning" thing and its god damn well done! For the money and time invested new bearing are just a good idea, its the first money I have spent so far on 26/4997 since I started on the chassis other than the black beauty, I had bought a few parts in advance, like top ball joints but not much else. I guess that makes it a bit over $200 so far, I just wish that donuts and shocks weren't so much money. Anyway I got the press out along with the camera and snap ring pliers and a few other needed bits and here is the results.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Continued:

I missed a couple of steps like showing when you install the small snap rings on the axle shafts but if you don't know that get someone else to do the work.

I missed a couple of steps like showing when you install the small snap rings on the axle shafts but if you don't know that get someone else to do the work.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Hi Gary,

I know that the rear bearings are all sealed for life. But, a secondary set of metal dustshields/spacers for the rear, inner, hub bearings is called for, as per the parts book and as supplied recently when I changed my rear bearings.

Regards,

Colin.

I know that the rear bearings are all sealed for life. But, a secondary set of metal dustshields/spacers for the rear, inner, hub bearings is called for, as per the parts book and as supplied recently when I changed my rear bearings.

Regards,

Colin.

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 631

- Joined: 04 Oct 2003

fatboyoz wrote:Hi Gary,

I know that the rear bearings are all sealed for life. But, a secondary set of metal dustshields/spacers for the rear, inner, hub bearings is called for, as per the parts book and as supplied recently when I changed my rear bearings.

Regards,

Colin.

Hi Colin

You are correct in that the Issue 18 upright uses the dust shield but those didn't come along until later in the Elan production (45/7743 - 36/7762). This happened at the same time as the wider inner bearing. I stated that I was using the 6206-2RS bearings and I guess I was negligent in stating that I was doing an Issue 16 upright but I did state it was for 26/4997 so I thought I was close enough with my description, I should have been more specific I guess. Here is the Issue 18 upright and the dust shied installed, I do not believe that there is sufficient room in the issue 16 for the dust shield and I don;t believe that the drive axle is relieved for the shield either.

Gary

Friday June 1st 2:00pm

I have a set of LF14 calipers that have been rebuilt that I was going to use but they have a bit of patina on them, they have not been painted and have there original plating still on them with minor surface rust starting to bleed through. I looked at the original front calipers and though that they may come apart fairly easy so I had at them this morning. they had brand new pads and it looked to be a fresh rebuild kit installed back in 1969 or there abouts. I put some air pressure to them and the pistons moved. The first came apart easy and the next one looked like the first but was a bit more stubborn so I raised the pressure to 170 psi and tried again and one piston moved. I clamped that piston and put the air back on and nothing so I got the chisel out and hit it inside the piston with the air on and it decided to see things my way after about 15 minutes of gentle persuasion. I blasted both sets of halves and taped off the areas that I didn't want painted and then made them black.

Sunday June 3rd 05:50pm

Yesterday it rained all day so I didn't do a lot, I had gotten the engine-block for 26/4997 down from the attic earlier in the week and did nothing with it. It had been up there as a bare block for the last 15 years and it was looking a bit on the decrepit side with a fair amount of surface rust. I had bought a couple of wire wheels, one 3 inch for the bores and one 2 inch for the crank journals so Friday evening I made some rust dust just so I can get them measured and get some relatively good readings. I don't know how long its been apart, when I bought the S2 it was apart and the crankshaft was at the machine shop so I don't even remember if it had pistons. I got the crankshaft several weeks after I bought the Elan and was happy to even get it. There is no ridge on the bores so I am hoping that it will measure ok and a set of standard pistons can be used and just give it a light hone. I am usually quite hopeful and then get the real news that its about as bad as it gets. Anyway I did a bit more cleaning on it yesterday and cleaned out the rust goo in the bottom of the coolant passages. Today the rain had stopped and in between the mist and sun I did some sand blasting, I needed 2 good rear rotor for Tingles body, the Chassis that I called the two bit whore had a pair of new 20 year old rear rotors but I moved them over to 26/4997 as they are going on the better of the two chassis. that left me needing a pair so I measured the thicknesses again of the stack of 19 rotors and pulled out the 6 thickest, all of them .360 inch or better and blasted 9 sides of the 12 side, one side just looked like shit so I didn't finish the other but 4 rotors look good enough so I'll use the best two and save the other to for the next build, yes number 4 will start some time and I just need to figure out whats good and whats not. I have a new Spyder space frame that I got from Jim Gordon 8 or 9 years ago and it will be used under 36/6292 (the Ugly Flaired Coupe). I didn't take any before pictures of the rotors but they were fairly rusty, after sandblasting they look pretty good and I'll paint the centers maybe tomorrow if the weather improves.

Monday June 4th 10:00am

No painting today, we seem to be in our late March weather pattern that we skipped 2 months ago. About 50F, light winds out of the Northeast at 20 to 30 mph and the spring tides put the sandblasting area under water last night. About 10 inches of water where I was sitting blasting rotors yesterday, glad I clean up and put stuff away every time I use it.

June 12th 4:00pm

I got the rotor centers papered and painted a couple days ago, I blasted another pair of front hubs seeing I had the black paint out and they were handy and not a lot of blasting to do. Had some time off due to the fact that I really need to spend some money on parts and though I would just think about it for a bit, I am still thinking so instead of taking more time off I got on with some other stuff that could be blasted and painted. I have been thinking of the wheels that I want to use on Tingles body with the big flairs and just cant spend any money so the alternate plan is to use the 6 and 7 inch Jap Magna wheels that came with the Ugly Flaired Coupe and that meant I needed some knock-on hubs. I looked around and saw a pair of Plus2 rear hubs and that seems like a good use for them with the 7 inch Jap Magna wheels. For the fronts I found a pair of stock Elan knock-ons and blasted them, While looking for other stuff I stumbled over a pair of LF14 calipers that were out in the shed, probably the last pair that still had the pistons still in them. I cranked up the compressor to 170 PSI and had at them, took about an hour to get all 4 pistons out and blasted them too. The weather was still good so I got out masking tape and then the paint and sprayed them all. Not a lot done but one less thing to do while I get around to the inevitable of spending more money, I guess I am a couple steps closer of getting the parts for the Spyder space frame ready, nothing done is wasted, just another step on clearing the backlog of Elans so that I can get serious about the next projects that are filling up the plate...

Wednesday June 13th 8:20am

Not going to get a lot done today, more rain. I figured I would get the red/green demarcation put back on the hubs. I guess I could have just got the brush out (and I did) but I like to put the paint where it is supposed to go so I taped off the hubs again so that the mess I made was where it belonged. Lotus probably had it done with a mask but that seemed like a lot of work so paper and tape for me, I guess I have another couple of pairs to do but I would probably loose the mask if I made on before I did those so this is good enough for me.

Top photo - just taped and papered

Middle - Hunter green 90% and satin black 10% applied with a brush

Bottom - I.H. Red applied to the other pair

Seem like a lot of work to do but so is getting the hubs on the wrong side if I mess up

Friday June 15th 9:00pm

Not much done today but I found a 3/4 inch front sway bar and thought that it would be nice addition to the sows ear chassis that is going under Tingles C production body. I have a 5/8 in place currently but I think that I'll get another pair of $7 urethane bushes and install the bar. I blasted the bar and a pair of drop links, found a couple of other parts (4 bolt hub grease caps) and blasted them also. I didn't have a lot to paint but I weighed out 100 grams of satin black and used most of it. No photos (they all look the same I guess) but I got something done and the sway bar that comes off can go in the pile for the Spyder space frame.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

I'm just as likely to edit a post as to post a reply if I am the last person to post the last reply. I have said before, I am not into post counts like some here. Anyway this reply is necessary as I have some more pictures to post and 10 is the most in a reply. The last reply started almost 3 weeks ago and things have slowed down due to I don't like spending money that may be needed for real things in life but I want to keep working and making progress so I spend some when I have to and move on to other things that need to be done. Some caliper pistons arrived today and they will be going in sometime this week. I was continuing with my dashboard project that was an on the cheap thing as I had everything to do it just not the motivation to start woodworking. The motivation was I didn't feel like sandblasting and painting so the dashboard floated to the top of the list of things that needed to get done. Nearly 3 years and sometimes shit happens.

elan-f14/elan-dashboard-needed-for-pattern-t19391.html

Anyway I wanted to see how things fit so this morning I pulled back the EPDM membrane that has covered Tingles C production body for the last 7 years and looked at what needed to be done to get the dash to fit.

I figured it was going to need some work and I was right, Lotus molded the S2 body shell and then trimmed it so that it could be either LHD or RHD in the molding shop and then when an order was received then nipped off the tab that the steering column bracket wasn't bolted through so the glove box could be installed. Anyway I fitted the dashboard and marked the holes in the body that the dash bolted to and it was clear that I needed the tab glued back on and I was out of resin again.

It was pretty early so I made coffee and read the latest here and figured I would go an cut the lawn at my folks house while they were away. The 1964 Wheelhorse lawn tractor started right up, that was a good year, same year the body was molded. When I finished I went over to see Willy and borrowed a cup (well it was a pint) of resin and mat scraps while I was there to glue the tab back on. I got home about 11am and got some cardboard, wax paper and masking tape out to make the el cheep-o mold. I tore some mat to layup and then mixed up a bit resin. and did the underside of tab first.

I like fiberglass work as it gives you some time to think a bit between layups. I had some lunch and read some more internet stuff and went back out a took a photo or two.

It wasn't long before the glass hardened and I pulled away the carboard and wax paper to see what I had done. It looked ok and I ground the front to level up the front edge before I gave the front some glass

I laid up the front and gave it a few extra layers of mat as I wanted it to kick so I could finish shaping it out today. It was a bit thick in places (5/16inch) but that was near the bottom that was getting cut off anyway. more like a fat 3/16 where things were going to remain so I had enough to shape out.

I pulled out the saw-all and trimmed the tab to shape, I used the sanding block with some 80 grit to flatten the front and took a bit off the back too to get it down to the propper thickness for the steering column clamp.

not a lot done but sometimes you need an off day to just say that this stuff is not all that important. The bottom line is someething got done that needed to be and thats enough sometimes...

elan-f14/elan-dashboard-needed-for-pattern-t19391.html

Anyway I wanted to see how things fit so this morning I pulled back the EPDM membrane that has covered Tingles C production body for the last 7 years and looked at what needed to be done to get the dash to fit.

I figured it was going to need some work and I was right, Lotus molded the S2 body shell and then trimmed it so that it could be either LHD or RHD in the molding shop and then when an order was received then nipped off the tab that the steering column bracket wasn't bolted through so the glove box could be installed. Anyway I fitted the dashboard and marked the holes in the body that the dash bolted to and it was clear that I needed the tab glued back on and I was out of resin again.

It was pretty early so I made coffee and read the latest here and figured I would go an cut the lawn at my folks house while they were away. The 1964 Wheelhorse lawn tractor started right up, that was a good year, same year the body was molded. When I finished I went over to see Willy and borrowed a cup (well it was a pint) of resin and mat scraps while I was there to glue the tab back on. I got home about 11am and got some cardboard, wax paper and masking tape out to make the el cheep-o mold. I tore some mat to layup and then mixed up a bit resin. and did the underside of tab first.

I like fiberglass work as it gives you some time to think a bit between layups. I had some lunch and read some more internet stuff and went back out a took a photo or two.

It wasn't long before the glass hardened and I pulled away the carboard and wax paper to see what I had done. It looked ok and I ground the front to level up the front edge before I gave the front some glass

I laid up the front and gave it a few extra layers of mat as I wanted it to kick so I could finish shaping it out today. It was a bit thick in places (5/16inch) but that was near the bottom that was getting cut off anyway. more like a fat 3/16 where things were going to remain so I had enough to shape out.

I pulled out the saw-all and trimmed the tab to shape, I used the sanding block with some 80 grit to flatten the front and took a bit off the back too to get it down to the propper thickness for the steering column clamp.

not a lot done but sometimes you need an off day to just say that this stuff is not all that important. The bottom line is someething got done that needed to be and thats enough sometimes...

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Total Online:

Users browsing this forum: No registered users and 18 guests