Drilling a hole in fibreglass/fiberglass...

16 posts

• Page 1 of 2 • 1, 2

A dumb question, no doubt, but does anybody have a guaranteed way of drilling holes in fibreglass without damaging the surrounding area?

Once in a while all goes well but, too often, I find that half way through the drilling the bit will suddenly grab onto the glass/weave and then, in a heartbeat, rip the rest of the way through, damaging the area surrounding the hole. Needless to say, this is very annoying on finished areas of the body.

I've scanned the web to find this question in several places, mostly boat forums, but with no good replies.

And at what size is a hole saw the right tool, as opposed to a drill?

Nick

Once in a while all goes well but, too often, I find that half way through the drilling the bit will suddenly grab onto the glass/weave and then, in a heartbeat, rip the rest of the way through, damaging the area surrounding the hole. Needless to say, this is very annoying on finished areas of the body.

I've scanned the web to find this question in several places, mostly boat forums, but with no good replies.

And at what size is a hole saw the right tool, as opposed to a drill?

Nick

-

elanner - Fourth Gear

- Posts: 546

- Joined: 14 Sep 2010

The standard way to reduce the tendency for a drill to grab when breaking through the back surface of soft materials is to alter the angle of the cutting face on the drill bit.

The leading surface is ground to be in line with the drill axis thus removing the undercut which would pull the drill through like a screw, sometimes violently.

This is useful on copper, brass, perspex and thin sheet material. It may well work OK on fibreglass.

It can sometimes be sufficient to just remove a small area using a hand stone. The cutting edge then still has a sharp edge but no undercut and does not pull the drill forward.

Hope this helps

Eric in Burnley

1967 S3SE DHC

PS, For a holesaw, you may be limited by available sizes of saw. The smallest I have is 19mm.

A cone cutter or stepped cutter may work well and certainly won`t grab.

The leading surface is ground to be in line with the drill axis thus removing the undercut which would pull the drill through like a screw, sometimes violently.

This is useful on copper, brass, perspex and thin sheet material. It may well work OK on fibreglass.

It can sometimes be sufficient to just remove a small area using a hand stone. The cutting edge then still has a sharp edge but no undercut and does not pull the drill forward.

Hope this helps

Eric in Burnley

1967 S3SE DHC

PS, For a holesaw, you may be limited by available sizes of saw. The smallest I have is 19mm.

A cone cutter or stepped cutter may work well and certainly won`t grab.

- ericbushby

- Coveted Fifth Gear

- Posts: 1354

- Joined: 13 Jun 2011

This is what I learned during my past life (eight years) in the motorcycle helmet industry. We drilled a lot of holes.

I tape the surface where the hole will be drilled to reduce chipping of the surface. The size of the hole dictates the type of drill used. Under 1/4" I use standard 135 degree,HSS drill bits, over that use brad point bits. If you make a pilot hole, make it small and don't drill all the way through the panel. The glass is brutal to drill bits that's why I stay with HSS, <$$.

The trick to prevent what you are describing is to use medium to faster drill speed and very low pressure. Let the drill do the work. Fiberglass will not act as a heat sink for the drill bit so watch for the bit getting too hot and gumming up. That's where that grab part way through comes from. Cool it off as needed to prevent binding.

I tape the surface where the hole will be drilled to reduce chipping of the surface. The size of the hole dictates the type of drill used. Under 1/4" I use standard 135 degree,HSS drill bits, over that use brad point bits. If you make a pilot hole, make it small and don't drill all the way through the panel. The glass is brutal to drill bits that's why I stay with HSS, <$$.

The trick to prevent what you are describing is to use medium to faster drill speed and very low pressure. Let the drill do the work. Fiberglass will not act as a heat sink for the drill bit so watch for the bit getting too hot and gumming up. That's where that grab part way through comes from. Cool it off as needed to prevent binding.

Bud

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

- Bud English

- Fourth Gear

- Posts: 942

- Joined: 05 Nov 2011

I use a Dremel tool with cutting bits and if a big hole keep rounding it out. Gordon Sauer

- Gordon Sauer

- Fourth Gear

- Posts: 608

- Joined: 20 Aug 2004

All good advice above, but nobody is mentioning the reality that in drilling through your Elan, you are simultaneously drilling through two substances, not one. You are drilling through polyester resin, which is a piece of cake because it is merely soft plastic. You are also drilling past fiberglass strands embedded in the polyester, which are extraordinarily strong (why they are there in the first place!) and likely the source of your challenge.

To that, two recommendations:

1. If you can back up the area with a wooden block, it will help keep the drill from straying when it grabs.

2. Use a sharp drill at high speed.

The combination of these will help to keep the strands in the plastic from grabbing the drill shaft and wrapping around it before they are severed. This in turn will keep them from tearing up the area in which they are embedded.

Remember also that the plastic resin is 50 years old, so it is a lot more brittle when yanked on by fibers than it was when fresh.

To that, two recommendations:

1. If you can back up the area with a wooden block, it will help keep the drill from straying when it grabs.

2. Use a sharp drill at high speed.

The combination of these will help to keep the strands in the plastic from grabbing the drill shaft and wrapping around it before they are severed. This in turn will keep them from tearing up the area in which they are embedded.

Remember also that the plastic resin is 50 years old, so it is a lot more brittle when yanked on by fibers than it was when fresh.

- denicholls2

- Fourth Gear

- Posts: 552

- Joined: 23 Jan 2006

You will also end up with 'open' fibres round the hole so you may decide to seal it with resin.

- mikealdren

- Coveted Fifth Gear

- Posts: 1194

- Joined: 26 Aug 2006

Craven wrote:Only have basic knowledge but look at twist drill rake angle, a low angle that is more flat than pointed will reduce the bite of the drill.

Spot on reduce rake the same as you do for drilling sheet metal

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3758

- Joined: 06 Dec 2008

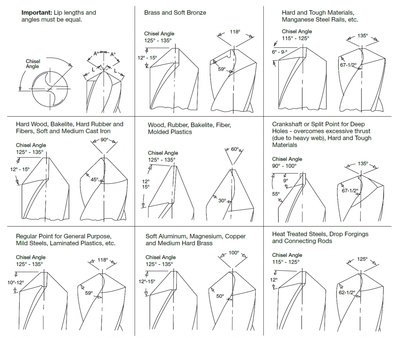

I've found this, which doesn't mention fibreglass, but I guess 135 degree bits are the ones to select:

https://www.regalcuttingtools.com/learn ... i-be-using

Nick

https://www.regalcuttingtools.com/learn ... i-be-using

Nick

-

elanner - Fourth Gear

- Posts: 546

- Joined: 14 Sep 2010

Hi Nick,

That`s very good, thankyou.

The one for brass and soft bronze has the `flat` on the cutting edge which I was trying to describe earlier.

Back in the day that is how I was shown to avoid sudden breakthrough on soft or thin material.

Eric in Burnley.

That`s very good, thankyou.

The one for brass and soft bronze has the `flat` on the cutting edge which I was trying to describe earlier.

Back in the day that is how I was shown to avoid sudden breakthrough on soft or thin material.

Eric in Burnley.

- ericbushby

- Coveted Fifth Gear

- Posts: 1354

- Joined: 13 Jun 2011

Try a Forstner bit?

They cut the edges almost first which you will readily see if you google them.

Available in many sizes.

Also work well for cutting holes when making your own gaskets, which I have done numerous times.

You didn?t mention size needed; my experience is wood type hole saws start at about 3/4 inch OD with a 1/4 inch pilot drill and go up for cutting OD from there.

Also if you can access the back side, can pre cut part way then drill from the front side using the pilot hole, should then reduce breakout.

The Forstner bits go from about 1/4 inch dia. to quite large. Could use same two side technique, likely smaller pilot.

Jack

They cut the edges almost first which you will readily see if you google them.

Available in many sizes.

Also work well for cutting holes when making your own gaskets, which I have done numerous times.

You didn?t mention size needed; my experience is wood type hole saws start at about 3/4 inch OD with a 1/4 inch pilot drill and go up for cutting OD from there.

Also if you can access the back side, can pre cut part way then drill from the front side using the pilot hole, should then reduce breakout.

The Forstner bits go from about 1/4 inch dia. to quite large. Could use same two side technique, likely smaller pilot.

Jack

- jk952

- Third Gear

- Posts: 258

- Joined: 04 Jan 2011

I have learned over the years, as a humble Sparky in my youth, as a less than humble technician in the RAF and as a multi-faceted (whatever that means) computer tech when computers went from massive buildings to something you can now stuff in your pocket...and along the way found it necessary, as an impecunious British car - and specifically Lotus owner - to skin the knuckles, smell of grease and oil/antifreeze etc to 'instinctively' understand what tools do and what they can do if not respected.

I have great mechanical sympathy (which I often ignore, sadly) but when I look at the actual knowledge thrown up HERE versus that 'kinda' knowledge I have gained over the years...I marvel.

What a resource this site is - and not just for the LL crowd (LL = Lotus Lovers) but for anyone who Googles the questions often raised here.

Well done all of you above who provided such informational gems.

I have great mechanical sympathy (which I often ignore, sadly) but when I look at the actual knowledge thrown up HERE versus that 'kinda' knowledge I have gained over the years...I marvel.

What a resource this site is - and not just for the LL crowd (LL = Lotus Lovers) but for anyone who Googles the questions often raised here.

Well done all of you above who provided such informational gems.

- Slowtus

- Third Gear

- Posts: 371

- Joined: 22 Sep 2017

16 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 11 guests