"Ford Kent Engine Back In Production"

65 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Thanks for the reply Gary

As far as I know the block would not contravene FIA appendix K regs, I was more concerned if there are any buildability issues using the original type of main cap. I had a reasonable price quoted from the UK importer and if I can convince myself there are no issues will order one.

Andy

As far as I know the block would not contravene FIA appendix K regs, I was more concerned if there are any buildability issues using the original type of main cap. I had a reasonable price quoted from the UK importer and if I can convince myself there are no issues will order one.

Andy

- batfish

- Third Gear

- Posts: 301

- Joined: 09 Oct 2003

batfish wrote:Thanks for the reply Gary

As far as I know the block would not contravene FIA appendix K regs, I was more concerned if there are any buildability issues using the original type of main cap. I had a reasonable price quoted from the UK importer and if I can convince myself there are no issues will order one.

Andy

Andy,

I'll check to see of the main caps from my 701M block will go on the new Ford Racing block. The new caps are substantial in comparison.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

CBUEB1771 wrote:I'll check to see of the main caps from my 701M block will go on the new Ford Racing block. The new caps are substantial in comparison.

Andy,

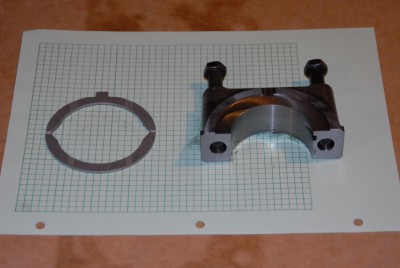

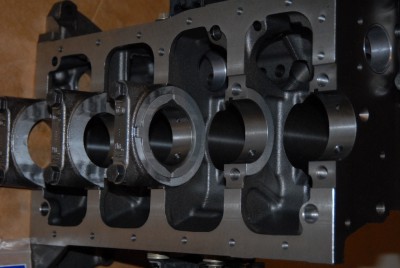

The 701M and new Ford racing main bearing caps are dimensionally very similar. The overall width (90 degrees to crank centerline) where they engage the block and centerline-to-centerline distance for the bolts or studs are the same. I fitted a couple of my 701M caps to the new block and they appear to fit perfectly. The main difference is that the area in which the new caps are at full "length" (parallel to crank centerline) is much larger than on the 701M as you can see in the photo. This was done to allow room for the recess to locate the Pinto 2000cc thrust bearings which are used in the new block. The photo shows this difference in caps taken from the #2 main bearing location, new cap on right. I also added a photo of the new center main cap with the thrust bearing recess and the Pinto 2000 upper and lower bearing pair. The only thing I would worry about with original or reproduction "round" caps is the thrust bearing. The Pinto 2000cc main journals are about 0.118 inches larger in diameter than the 701M/771M main journals so the inner and outer radii of these bearings are larger. The 701M/711M thrust bearings would float excessively in the new block. The Pinto thrust bearings are also not in complete contact with the thrust surfaces of the 701M/711M crankshaft because of the larger inner on outer radii. I think this is not an issue with the new block and caps because there are thrust bearings in both the block and cap. With a mix of new block and old style caps there will be less thrust bearing area in contact with the crankshaft.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

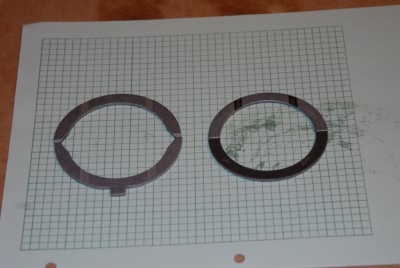

Here are photos of the Pinto 2000 thrust bearings install in the center main, block and cap. Also a photo showing the 701M/711M thrust bearing and the Pinto 2000 set. The lines in the graph paper are on 0.200 inch spacing.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

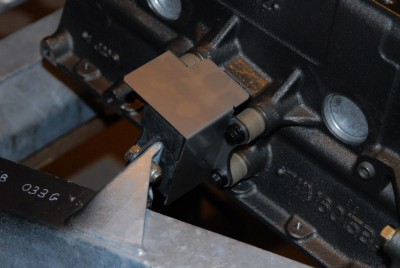

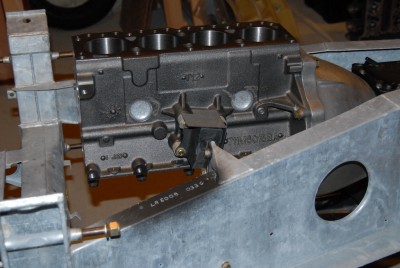

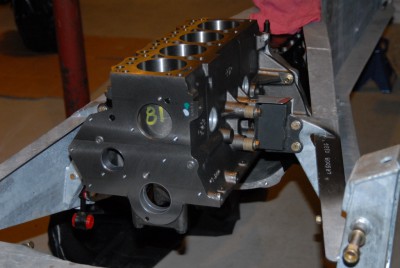

A few more photos from my trial fit of the new block to the Alan Voights T-9 conversion gearbox and the chassis. The washer packs I made up for the exhaust side engine mount total 0.64 inches (16.3 mm) thick and the bolts attaching the engine mounts to the chassis slip right in. The exhaust side engine mount heat shield and the anti-roll bar drop links with poly bushes are from Steve Taylor at Lotus Marques, formerly Elan Factory, in Oz.

http://www.lotusmarques.com/

http://www.lotusmarques.com/

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

bcmc33 wrote:If it's not too much trouble, please tell me the depth of the exhaust side engine mount and the cylinder head stud tapped holes.

Brian,

The cylinder head bolt/stub holes are quite deep. They are 7/16 UNC and threaded about 1.75" (44 mm) deep below the deck. On my 701M block they are more like 1.38" (35 mm) deep. This makes me suspect that the new tall and short deck blocks are the same casting and that the "Lotus" block is machined down more. I'll have to see how deep the water jackets are below the deck to confirm. This would make sense if Ford Racing is only planning to make a relatively small numbers of blocks.

Russ

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

CBUEB1771 wrote:The cylinder head bolt/stub holes are quite deep. They are 7/16 UNC and threaded about 1.75" (44 mm) deep below the deck. On my 701M block they are more like 1.38" (35 mm) deep. Russ

Thanks for the info, Russ.

So there will be no concern in decking by 5mm to make a 1700cc motor.

Now what about the exhaust side engine mount holes? I like to have the engine mount fixed to the engine without spacers so will need to remove 1/2" and use my usual plate spacer on the other side.

Brian Clarke

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

-

bcmc33 - Coveted Fifth Gear

- Posts: 1708

- Joined: 10 Apr 2006

bcmc33 wrote:So there will be no concern in decking by 5mm to make a 1700cc motor.

Now what about the exhaust side engine mount holes? I like to have the engine mount fixed to the engine without spacers so will need to remove 1/2" and use my usual plate spacer on the other side.

Brian,

Hang on a bit, I said I need to check the depth of the water jacket below the deck. I don't know what you are thinking about regarding pistons and connecting rods. With the right connecting rods (BDD length) and pistons you don't need to deck the block at all. Of course that means other issues with bonnet and exhaust system clearance, etc. I'll check the exhaust side bolt holes depth for the engine mount when I am back from work travel. I am assuming there is nothing unusual there, if you want the crankshaft centerline to be near the chassis centerline you will need spacers on the exhaust side. Am I missing something?

Russ

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

CBUEB1771 wrote:Hang on a bit, I said I need to check the depth of the water jacket below the deck. I don't know what you are thinking about regarding pistons and connecting rods. With the right connecting rods (BDD length) and pistons you don't need to deck the block at all. Of course that means other issues with bonnet and exhaust system clearance, etc.

Russ,

The 711M block needs to be decked about 5mm and rebored to suit the Twin Cam pistons for use with the 711M crank and conrods.

CBUEB1771 wrote:I'll check the exhaust side bolt holes depth for the engine mount when I am back from work travel. I am assuming there is nothing unusual there, if you want the crankshaft centerline to be near the chassis centerline you will need spacers on the exhaust side. Am I missing something?

I fix the engine mount directly to the engine and use a plate spacer on the other side of the mount to the chassis. My last two engines have been 681M blocks which is where I did the modification originally to get the mount away from the hot #2 header pipe as I'd had a couple of mount failures due to the heat.

The 711M & 701M blocks have the mount base 1/2" thicker than the 681M block so I need to know if it's OK to remove 1/2" and retain sufficient thread length. Maybe I'll need to drill and tap the holes deeper, or maybe make a shorter plate spacer -- there's plenty of time for me to make up my mind on which action to take.

As you can see, there's no bounds to my playing with my favourite toy.

Brian Clarke

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

-

bcmc33 - Coveted Fifth Gear

- Posts: 1708

- Joined: 10 Apr 2006

bcmc33 wrote:The 711M & 701M blocks have the mount base 1/2" thicker than the 681M block so I need to know if it's OK to remove 1/2" and retain sufficient thread length. Maybe I'll need to drill and tap the holes deeper, or maybe make a shorter plate spacer -- there's plenty of time for me to make up my mind on which action to take.

Brian,

Now I understand your plan. I'll get the tapped hole depths for the exhaust side engine mount to you this coming weekend. I was thinking about using the longer BDD connecting rods to get the the ratio of connecting rod C/L-C/L to stroke/2 dimensions preferred by Cosworth.

Russ

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

Hi Brian

I would like to know more about the Lotus replacement block but no one that I know has bought one. What is good about it (from the specs posted in the Ford racing site) is that the deck height has been increased from 7.78 inch to 7.9 inch making it possible to run the 1600 cranks in them with the stock length connecting rods and stock compression height pistons.

7.9 - 4.8 = 3.1 (deck height minus the stock rod length)

3.1 - 1.53 = 1.57 (the above minus one half the stroke)

With stock height pistons used only minor decking of say right around .030 inch is needed

Is this what Ford racing has done and just increased the price by $400? I don't truely know and I sound (and feel) like a broken record again asking. My guess is there is a bit of a difference to them. I would hope that Ford Racing listened to the folks that are there customers and made it so the bores could be opened up. They were talking on lowering the main oil gallery cross feed between cylinders 2 and 3 so that the chances of breaking through with large overbores was minimized. There were several other changes that escape me at the moment but I hope that they listens to the buyers and not the bean counters. The engine mounts may be narrower too as they offer it as a replacement for the Lotus block (the 701 had narrow blocks at the engine width). Until someone buys one we won't know. Anyway spend you money and build the engine the way you want to. Short rods are a good thing for torque, long rods benefit horsepower. If it were a street engine I would build the lotus replacement block where torque is a fine thing to have in excess.

Gary

I would like to know more about the Lotus replacement block but no one that I know has bought one. What is good about it (from the specs posted in the Ford racing site) is that the deck height has been increased from 7.78 inch to 7.9 inch making it possible to run the 1600 cranks in them with the stock length connecting rods and stock compression height pistons.

7.9 - 4.8 = 3.1 (deck height minus the stock rod length)

3.1 - 1.53 = 1.57 (the above minus one half the stroke)

With stock height pistons used only minor decking of say right around .030 inch is needed

Is this what Ford racing has done and just increased the price by $400? I don't truely know and I sound (and feel) like a broken record again asking. My guess is there is a bit of a difference to them. I would hope that Ford Racing listened to the folks that are there customers and made it so the bores could be opened up. They were talking on lowering the main oil gallery cross feed between cylinders 2 and 3 so that the chances of breaking through with large overbores was minimized. There were several other changes that escape me at the moment but I hope that they listens to the buyers and not the bean counters. The engine mounts may be narrower too as they offer it as a replacement for the Lotus block (the 701 had narrow blocks at the engine width). Until someone buys one we won't know. Anyway spend you money and build the engine the way you want to. Short rods are a good thing for torque, long rods benefit horsepower. If it were a street engine I would build the lotus replacement block where torque is a fine thing to have in excess.

Gary

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

bcmc33 wrote:The 711M & 701M blocks have the mount base 1/2" thicker than the 681M block so I need to know if it's OK to remove 1/2" and retain sufficient thread length. Maybe I'll need to drill and tap the holes deeper, or maybe make a shorter plate spacer -- there's plenty of time for me to make up my mind on which action to take.

Brian,

The engine mount bosses on the exhaust side of the new block are tapped just over 1" deep. Chasing with a bottoming tap will get you close to 1.25" of thread.

Russ

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

CBUEB1771 wrote:The engine mount bosses on the exhaust side of the new block are tapped just over 1" deep. Chasing with a bottoming tap will get you close to 1.25" of thread.

Russ

Good info, Russ, thank you.

Brian Clarke

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

-

bcmc33 - Coveted Fifth Gear

- Posts: 1708

- Joined: 10 Apr 2006

garyeanderson wrote:Hi Brian

I would like to know more about the Lotus replacement block but no one that I know has bought one. What is good about it (from the specs posted in the Ford racing site) is that the deck height has been increased from 7.78 inch to 7.9 inch making it possible to run the 1600 cranks in them with the stock length connecting rods and stock compression height pistons.

7.9 - 4.8 = 3.1 (deck height minus the stock rod length)

3.1 - 1.53 = 1.57 (the above minus one half the stroke)

With stock height pistons used only minor decking of say right around .030 inch is needed

Is this what Ford racing has done and just increased the price by $400? I don't truely know and I sound (and feel) like a broken record again asking. My guess is there is a bit of a difference to them. I would hope that Ford Racing listened to the folks that are there customers and made it so the bores could be opened up. They were talking on lowering the main oil gallery cross feed between cylinders 2 and 3 so that the chances of breaking through with large overbores was minimized. There were several other changes that escape me at the moment but I hope that they listens to the buyers and not the bean counters. The engine mounts may be narrower too as they offer it as a replacement for the Lotus block (the 701 had narrow blocks at the engine width). Until someone buys one we won't know. Anyway spend you money and build the engine the way you want to. Short rods are a good thing for torque, long rods benefit horsepower. If it were a street engine I would build the lotus replacement block where torque is a fine thing to have in excess.

Gary

Hello Gary,

Please give Jay Ivey a call. He can give you all of the information you need to make a decision. He did much of work with Ford Racing to make the replacement block as useful as possible for everyone. He loves these engines and knows them really well, all iterations of them.

http://www.iveyengines.com/

Best regards,

Dan Wise

There is no cure for Lotus, only treatment.

-

StressCraxx - Coveted Fifth Gear

- Posts: 1276

- Joined: 26 Sep 2003

65 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Total Online:

Users browsing this forum: No registered users and 12 guests