Fitting a Carter 4070 pump

39 posts

• Page 3 of 3 • 1, 2, 3

Simon -- You said "I do have sheet of rubber betwixt body and bracket " Just to be clear about the use of those rubber sheets: the rubber sheets don't do any good unless the fasteners connecting the bracket to the body are not themselves completely isolated by rubber. IOW if any metal object touches both the bracket and the body, the rubber sheets accomplish almost nothing, because the vibration is transmitted from the bracket, along the fastener and directly into the bodywork not matter how much rubber there is elsewhere.

The rubber isolators that come with the carter fuel pump are relatively stiff and thin grommets. You might consider replacing those with a softer mounting. In the US we have a wonderful industrial supply McMaster-Carr that has lots of these in different configurations. See:

http://www.mcmaster.com/#vibration-damping-sandwich-mounts

You would want to choose the ones with the lowest "Cap. per Mount" to get the softest rubber.

This is how the Facet Interrupter pumps were mounted.

The rubber isolators that come with the carter fuel pump are relatively stiff and thin grommets. You might consider replacing those with a softer mounting. In the US we have a wonderful industrial supply McMaster-Carr that has lots of these in different configurations. See:

http://www.mcmaster.com/#vibration-damping-sandwich-mounts

You would want to choose the ones with the lowest "Cap. per Mount" to get the softest rubber.

This is how the Facet Interrupter pumps were mounted.

- awatkins

- Second Gear

- Posts: 88

- Joined: 23 Sep 2015

simonknee wrote:Hi Rohan,

That makes sense and the fact that the float system itself will alter flow and hence the measured pressure goes some way to explain why a working pressure range is considered appropriate. This leads me back to an earlier question of where should you attach a pressure gauge to look for the 2-4psi? I don't have a take off point yet so all I could measure is the Carter 4070 straight into the guage - 4psi - this I assume indicates the maximum pressure it can do.

Also can you give me an answer to what would changing the regulator setting from 2-4psi do to the fuel level with the engine running and fuel flowing i.e. if I had a regulator and changed the setting on it do I need to reset my float level?

I found my fuel reg this morning so I am nearly in a position to provide my own answers. I don't trust the calibrated markings on it (mainly because ten years ago I fiddled with the grub screw) How would you set a regulator? Again this takes me back to where should I fit the gauge to get useful readings?

Simon

The pressure regulator is again a simple proportional controller. It senses the pressure downstream of the regulator compared to a set point established by the adjusting screw or knob and if the pressure drops it opens a valve to let fuel flow downstream to raise the pressure. If it is set at 4 psi downstream pressure with no flow as the flow increases the pressure will drop a little in order for the valve in the regulator to open sufficiently to supply the required fuel. Where the regulator is located between the pump discharge and carb inlet is probably not critical especially if you have larger fuel lines.

Depending on what pressure you set the regulator at there will be a small affect on fuel level for the carb float valve to close off against this pressure. However over the 2 to 4 PSI range we are talking about that affect will be minimal and not worth worrying about.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

Just managed 20 minutes of tinker time in the garage.

Adjusted the fuel regulator using my fuel gauge. The pump was just pushing through the regulator and into the gauge. I had to release the pressure after each tweak of the grub screw or it "latched" at the highest value. Obvious behavior once I thought how the diaphragm operates.

So then I lashed up the regulator at the carbs. Got the car running and had a look at the fuel level in the bowls. It might have dropped by 1- 2mm when restricting the fuel pressure down to the 1psi setting on the regulator. So, as you say Rohan, within the 2-4psi range this is negligible.

So for my next trick I need a 1/4NPT junction between the carbs so I can measure the pressure whilst the engine is running. To be honest the whole process has made me completely happy to run the Carter 4070 without any regulator. I know that it can't deliver more than 4 psi at the carbs. When running the pressure will be somewhat less.

Digging out the Sytec (Proline, etc) regulator has reminded my of a fun "fault" mode they exhibit. There you are tinkering under the bonnet, then all done off for a run. Car is great for a little while until you put your foot down then cough, splutter, pop, no power. How long does it take you to find that you lent on the dial on the top of regulator and twisted it round to 1psi by accident? Too long as I recall

Adjusted the fuel regulator using my fuel gauge. The pump was just pushing through the regulator and into the gauge. I had to release the pressure after each tweak of the grub screw or it "latched" at the highest value. Obvious behavior once I thought how the diaphragm operates.

So then I lashed up the regulator at the carbs. Got the car running and had a look at the fuel level in the bowls. It might have dropped by 1- 2mm when restricting the fuel pressure down to the 1psi setting on the regulator. So, as you say Rohan, within the 2-4psi range this is negligible.

So for my next trick I need a 1/4NPT junction between the carbs so I can measure the pressure whilst the engine is running. To be honest the whole process has made me completely happy to run the Carter 4070 without any regulator. I know that it can't deliver more than 4 psi at the carbs. When running the pressure will be somewhat less.

Digging out the Sytec (Proline, etc) regulator has reminded my of a fun "fault" mode they exhibit. There you are tinkering under the bonnet, then all done off for a run. Car is great for a little while until you put your foot down then cough, splutter, pop, no power. How long does it take you to find that you lent on the dial on the top of regulator and twisted it round to 1psi by accident? Too long as I recall

Simon

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

-

simonknee - Third Gear

- Posts: 392

- Joined: 18 Sep 2003

awatkins wrote:Simon -- You said "I do have sheet of rubber betwixt body and bracket " Just to be clear about the use of those rubber sheets: the rubber sheets don't do any good unless the fasteners connecting the bracket to the body are not themselves completely isolated by rubber. IOW if any metal object touches both the bracket and the body, the rubber sheets accomplish almost nothing, because the vibration is transmitted from the bracket, along the fastener and directly into the bodywork not matter how much rubber there is elsewhere.

I was contemplating the very same thing and have a few ideas in mind to achieve this. One option would be to do away with the carter angle bracket completely. Instead I have seen a pump mounted with a U-bracket around the cylindrical body (like a coil) but isolated from the U clamp with a wrap around of neoprene first.

However my first test will be to let it dangle in the air supported from below by a block of foam. Then I can assess what the best case scenario will be. It may be diminishing returns already. To be honest in the current setup it is very quiet after I've been running for 10 minutes. I can only just hear it above the exhaust at idle.

Simon

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

-

simonknee - Third Gear

- Posts: 392

- Joined: 18 Sep 2003

oldchieft wrote:My guess would be you may be drawing air into the system, to get a good lead on whats going on, fit some clear hose at the carburettor inlet.

Jon the Chief

Liking the clear hose idea Jon.

Simon

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

-

simonknee - Third Gear

- Posts: 392

- Joined: 18 Sep 2003

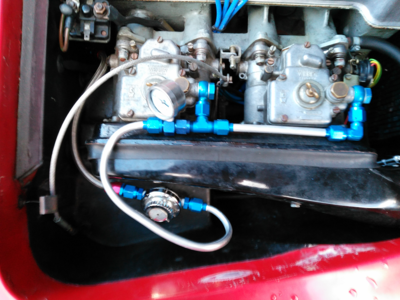

It's not pretty, yet, but it does the job.

What have I learnt?

1. That measuring pressure by slapping a gauge on the output of a pump is inaccurate (possibly due to air pockets with nowhere to go) - I got 4psi. Once I had 1/8npt take-off adaptor in place for the pressure gauge I could then see that the Carter 4070 delivers 6-7psi at the carbs when the engine is running.

2. The Carter 4070 is a bit hot pressure wise and a regulator is a good idea.

3. The way I calibrated the regulator (grub screw in the center of the dial) by attaching a gauge to the output did translate pretty well to the running conditions. Setting the reg to 3psi on it's dial produced 3psi at the gauge when running.

4. Without the regulator the pressure drops (like Rohan said) when your foot goes down. Perhaps 1psi for a blip of the throttle. With the regulator the pressure now holds station at whatever you set. Fairly obvious why - it's doing it's regulatory job!

5. I need a nicer under-bonnet setup. Perhaps one of those Holley's that has the inlet on the bottom would allow a neat install.

In all all this has been another fun learning experience!

Question: is having a regulated low pressure supply to the carbs better/worse/same as using a pump that supplies the low pressure in the first place but that varies with "load". My instinct thinks regulated is better but then that's my electrical head that likes regulated supplies over unregulated ones?

What have I learnt?

1. That measuring pressure by slapping a gauge on the output of a pump is inaccurate (possibly due to air pockets with nowhere to go) - I got 4psi. Once I had 1/8npt take-off adaptor in place for the pressure gauge I could then see that the Carter 4070 delivers 6-7psi at the carbs when the engine is running.

2. The Carter 4070 is a bit hot pressure wise and a regulator is a good idea.

3. The way I calibrated the regulator (grub screw in the center of the dial) by attaching a gauge to the output did translate pretty well to the running conditions. Setting the reg to 3psi on it's dial produced 3psi at the gauge when running.

4. Without the regulator the pressure drops (like Rohan said) when your foot goes down. Perhaps 1psi for a blip of the throttle. With the regulator the pressure now holds station at whatever you set. Fairly obvious why - it's doing it's regulatory job!

5. I need a nicer under-bonnet setup. Perhaps one of those Holley's that has the inlet on the bottom would allow a neat install.

In all all this has been another fun learning experience!

Question: is having a regulated low pressure supply to the carbs better/worse/same as using a pump that supplies the low pressure in the first place but that varies with "load". My instinct thinks regulated is better but then that's my electrical head that likes regulated supplies over unregulated ones?

Simon

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

'67 S3 FHC 36/7002

'69 +2 50/1370 (stolen '00)

-

simonknee - Third Gear

- Posts: 392

- Joined: 18 Sep 2003

I ran a Facet pump on my Elan back in the 70s. 168bhp at the wheels with no issues or any noise that I could hear.

At the end of the day, there isn't a single right answer. Whatever works for you is the way to go.

At the end of the day, there isn't a single right answer. Whatever works for you is the way to go.

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

39 posts

• Page 3 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: Stagmatt and 11 guests