Electric fuel pump install on a carburetor car

20 posts

• Page 2 of 2 • 1, 2

When I get to updating my fuel pump set up I plan to add fitting to the edge of the body/chassis near the location of the standard fuel pump (rear left corner of the engine bay). Something similair to the brass brake lines union that fasten to the chassis.

I'll then fit the fuel line to the lower connection and fuel feed to the carbs to the upper. Aim is to keep the fuel line out of the way at rear of the engine bay and give an easy places for connect/disconnecting the carb feed hose.

I'll then fit the fuel line to the lower connection and fuel feed to the carbs to the upper. Aim is to keep the fuel line out of the way at rear of the engine bay and give an easy places for connect/disconnecting the carb feed hose.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

Grizzly wrote:pharriso wrote:Bruce Crowthorne wrote:OK, so we seem to have covered the installation in the boot (trunk), but what about the engine end?

Bruce, I wondered about this & could not find a lot of information posted here.

I fitted a fuel pump blanking plate (without Oil deflector yet) & had a piece of copper pipe made up with the correct fittings to go between the supply line & the Carb fuel hose:

Do you remember what fittings you used? from memory i think it has compression fittings but not sure what size?

I haven't got round to removing the mechanical pump yet but it's leaking oil onto the starter so needs looking at, might be the time to do away with it completely.

Chris, the local hardware store made this up for me, Standard 1/4" Copper pipe with 2 flare fittings, they flared the copper with a 45 degree double flare.

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

OK... an update with detail on the Pipe & fittings used to fill in where the Mechanical pump used to be. The copper pipe is actually 5/16" Copper (OD) 3" long & the fittings standard 5/16 flares:

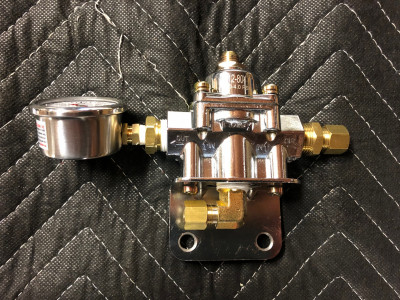

I originally had no pressure regulator as my pump is meant to be supply 2.5-4.5 psi. I did not have any flooding issues, but after a couple of weeks added a generic version of the Sytec Pro-flow pressure regulator installed in the trunk. After reading that it is good practice to have the pressure regulator as close as possible to the Carburettors I've installed a Holley 12-804 pressure regulator & Measureman pressure gauge under the hood (bonnet), mounted to the fuel pump mounting flange:

The Holley regulator comes with a mounting bracket, just had to enlarge 2 of the holes to match the Fuel pump mounting bolts:

For reference:

Plastic Fuel line uses 1/4" compression fittings

Metal line from Mechanical fuel pump to Carbs has 5/16" compression fittings

Holley 12-804 uses 3/8 NPT fittings throughout.

I originally had no pressure regulator as my pump is meant to be supply 2.5-4.5 psi. I did not have any flooding issues, but after a couple of weeks added a generic version of the Sytec Pro-flow pressure regulator installed in the trunk. After reading that it is good practice to have the pressure regulator as close as possible to the Carburettors I've installed a Holley 12-804 pressure regulator & Measureman pressure gauge under the hood (bonnet), mounted to the fuel pump mounting flange:

The Holley regulator comes with a mounting bracket, just had to enlarge 2 of the holes to match the Fuel pump mounting bolts:

For reference:

Plastic Fuel line uses 1/4" compression fittings

Metal line from Mechanical fuel pump to Carbs has 5/16" compression fittings

Holley 12-804 uses 3/8 NPT fittings throughout.

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

Hi Phil

Engine vibration may affect the regulator and alter its accuracy or shorten its life. Personally I would mount it in a suitable location on the body. In 9000 rpm race engines Everything attached to the engine suffers from the vibrations, less of an issue with road engines but still something to think about especially for a fairly delicate device like the regulator with its springs and diaphragm's and valves and seats

cheers

Rohan

Engine vibration may affect the regulator and alter its accuracy or shorten its life. Personally I would mount it in a suitable location on the body. In 9000 rpm race engines Everything attached to the engine suffers from the vibrations, less of an issue with road engines but still something to think about especially for a fairly delicate device like the regulator with its springs and diaphragm's and valves and seats

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

20 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 8 guests