Electric headlight assy

19 posts

• Page 1 of 2 • 1, 2

Quite a few have done this modification. It helps to know which car you have: Elan non-failsafe, failsafe, or Plus2, due to the number and location of the vacuum operating units. Various electric motors have been employed, with the MX5/Miata being popular, as the actuating arm is splined to the motor shaft, and can be placed in most any position. The arm makes a full 360 degree rotation from closed to open to closed. A 5 pin universal relay can take care of the electrical requirements. If using the above motor be careful, the motor operates very quickly with a lot of power, so keep ones fingers well out of the way. There are many discussions in the Mods section.

Rob Walker

26-4889

50-0315N

1964 Sabra GT

1964 Elva Mk4T Coupe (awaiting restoration)

1965 Ford Falcon Ranchero, 302,AOD,9",rack and pinion,disc,etc,etc,etc

1954 Nash Healey LeMans Coupe

Owning a Lotus will get you off the couch

26-4889

50-0315N

1964 Sabra GT

1964 Elva Mk4T Coupe (awaiting restoration)

1965 Ford Falcon Ranchero, 302,AOD,9",rack and pinion,disc,etc,etc,etc

1954 Nash Healey LeMans Coupe

Owning a Lotus will get you off the couch

- prezoom

- Coveted Fifth Gear

- Posts: 1176

- Joined: 16 Mar 2009

I bought the failsafe linkage bar for between the two pods for my plus two and a Mazda headlight motor and mounted it myself. I wired it so that switching the headlights on energised the motor to bring the pods up. Needed a bit of careful measurement and adjusting the length of the arm on the motor unit, but nothing too challenging.

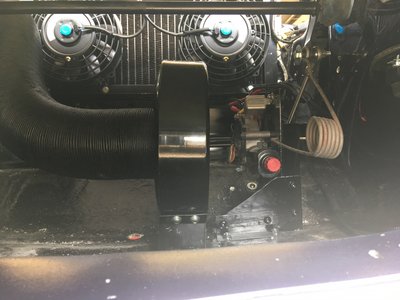

Photo below shows the view through the nose.

Photo below shows the view through the nose.

Change is inevitable, except from a vending machine!

- Bigbaldybloke

- Fourth Gear

- Posts: 889

- Joined: 16 May 2017

Bigbaldybloke wrote:I bought the failsafe linkage bar for between the two pods for my plus two and a Mazda headlight motor and mounted it myself. I wired it so that switching the headlights on energised the motor to bring the pods up. Needed a bit of careful measurement and adjusting the length of the arm on the motor unit, but nothing too challenging.

Photo below shows the view through the nose.

I made up a link bar many years ago, and am now operating on just one vacuum pod, but would like the reliability of electric operation. Do you have a limit switch at the fully up and down positions , or how do you control them ?

68 Elan +2, 70 Elan +2s

-

Foxie - Coveted Fifth Gear

- Posts: 1209

- Joined: 20 Sep 2003

The motor rotates 180 degrees between lights on/up and lights off/down. So the amount of lift is controlled by relative lengths of arm on motor and arm fastened to link bar.

With an 180 sweep the amount of lift from the motor is 2x arm "length", the headlights rotate ~90 degrees so you can use Pythagoras theory to calculate the lift needed for the link bar at the lights. If you can perfectly line up the motor the maths is very simple* but more likely it will be miss aligned and the maths a lot more complicated. Then there also some flex of the fiberglass to allow for.

So I just made a slotted arm for the motor so I could adjust the amount of lift and an adjustable length arm. Then did it by trail and error....

*(2 x Motor Arm length = sqrt(2x(link arm length^2))

With an 180 sweep the amount of lift from the motor is 2x arm "length", the headlights rotate ~90 degrees so you can use Pythagoras theory to calculate the lift needed for the link bar at the lights. If you can perfectly line up the motor the maths is very simple* but more likely it will be miss aligned and the maths a lot more complicated. Then there also some flex of the fiberglass to allow for.

So I just made a slotted arm for the motor so I could adjust the amount of lift and an adjustable length arm. Then did it by trail and error....

*(2 x Motor Arm length = sqrt(2x(link arm length^2))

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

The physical installation is covered in the previous reply, only comment would be choose your location for the motor carefully to get the best alignment for the linkage as it?s an arc not a straight line as with the vacuum pod.

Electrically the Mazda unit has several connections to it. An earth, a permanent live supply, a signal which when energised causes the motor to rotate the arm by 180 degrees and then stop there until the signal is removed which causes the arm to do another 180 degrees and return to the original position. There is also a micro switch built in that operates at one of the stop positions of the arm.

I used a signal taken from the headlights on switch to cause the motor to turn 180 degrees, this is the power to the dip switch.

I also have another bit of relay logic that recognises if the pods are down and I flash the headlights, it flashes the spot lights by the grill, if the pods are up it flashes main beam as normal.

I can provide a wiring diagram if required.

Electrically the Mazda unit has several connections to it. An earth, a permanent live supply, a signal which when energised causes the motor to rotate the arm by 180 degrees and then stop there until the signal is removed which causes the arm to do another 180 degrees and return to the original position. There is also a micro switch built in that operates at one of the stop positions of the arm.

I used a signal taken from the headlights on switch to cause the motor to turn 180 degrees, this is the power to the dip switch.

I also have another bit of relay logic that recognises if the pods are down and I flash the headlights, it flashes the spot lights by the grill, if the pods are up it flashes main beam as normal.

I can provide a wiring diagram if required.

Change is inevitable, except from a vending machine!

- Bigbaldybloke

- Fourth Gear

- Posts: 889

- Joined: 16 May 2017

Bigbaldybloke wrote:

<Snip>

I also have another bit of relay logic that recognises if the pods are down and I flash the headlights, it flashes the spot lights by the grill, if the pods are up it flashes main beam as normal.

I can provide a wiring diagram if required.

Yes Please !

68 Elan +2, 70 Elan +2s

-

Foxie - Coveted Fifth Gear

- Posts: 1209

- Joined: 20 Sep 2003

Headlamp, spot lamp and other wiring diagram for early Elan +2 that has the spotlights added beside the front intake. Easiest place to pick up the signal for the pod motor is where the column switch harness joins the main dashboard harness, just change the single bullet connector for a double one and connect in here, much easier than trying to get to the back of the lights switch in the dashboard and make a connection there. The spot light switch is a Lucas push/pull switch typically used on an MGB and it is fitted in place of the pod vacuum switch and has the original knob fitted to it with the lamp icon on it. looks original and can be returned to standard if required at a later date.

Beware when fiddling with the Mazda electric motor when setting up and adjusting the new pod linkage, it is very fast and powerful and could easily chop of a finger so ALWAYS isolate it completely from the power when your fingers are in there, you can turn the manual knob on the end of the motor to try out the linkage to the pods and if its wrong you can stop before you do any damage. I actually have two of the standard pod springs fitted so that the pods require minimal force to move them up or down. By carefully locating the bottom of the spring in the fore and aft direction, you can make it such that the springs go just over centre and actually hold the pods down without the motor linkage connected.

Beware when fiddling with the Mazda electric motor when setting up and adjusting the new pod linkage, it is very fast and powerful and could easily chop of a finger so ALWAYS isolate it completely from the power when your fingers are in there, you can turn the manual knob on the end of the motor to try out the linkage to the pods and if its wrong you can stop before you do any damage. I actually have two of the standard pod springs fitted so that the pods require minimal force to move them up or down. By carefully locating the bottom of the spring in the fore and aft direction, you can make it such that the springs go just over centre and actually hold the pods down without the motor linkage connected.

- Attachments

-

Headlamp wiring diagram rev 5.pdf

Headlamp wiring diagram rev 5.pdf- (414.32 KiB) Downloaded 442 times

Change is inevitable, except from a vending machine!

- Bigbaldybloke

- Fourth Gear

- Posts: 889

- Joined: 16 May 2017

Yep, I read the article by Dougal, very helpful. I went a different way in making the actual bracket for the Mazda motor but the theory and final layout are pretty much the same. My bracket was make from 3mm alloy sheet plus some 25mm alloy angle and 25mm square alloy tube. I bought the 3mm plate on ebay and the angle and square tube from B&Q. These were then cut, drilled and bolted together.

Saved me the bending and welding. Its handy if you have a rivnut tool as they make it easier and neater but its not essential. My second spring is on the right hand pod fixed to a simple bracket made from the 25mm square tube and mounted in the nosecone. I chose to modify the length of the motor arm and keep the failsafe tube linkage standard, but that's just personal preference, the end effect is the same. You need to do one or the other as the standard motor arm used with the standard linkage tube does not give quite enough lift on the pods.

Saved me the bending and welding. Its handy if you have a rivnut tool as they make it easier and neater but its not essential. My second spring is on the right hand pod fixed to a simple bracket made from the 25mm square tube and mounted in the nosecone. I chose to modify the length of the motor arm and keep the failsafe tube linkage standard, but that's just personal preference, the end effect is the same. You need to do one or the other as the standard motor arm used with the standard linkage tube does not give quite enough lift on the pods.

Change is inevitable, except from a vending machine!

- Bigbaldybloke

- Fourth Gear

- Posts: 889

- Joined: 16 May 2017

I just purchased tow linear actuators

One for the baby, second for thee +2

https://m.youtube.com/watch?v=_HLdt4Bhnto

One for the baby, second for thee +2

https://m.youtube.com/watch?v=_HLdt4Bhnto

Born, and brought home from the hospital (no seat belt (wtf)) in a baby!

Find out where the limits are, and start from there

Love your Mother

Earth

Find out where the limits are, and start from there

Love your Mother

Earth

-

h20hamelan - Coveted Fifth Gear

- Posts: 1957

- Joined: 25 Sep 2010

Spyder have produced a power supply for the Mazda motor to slow it down and make it less aggressive. I would assume it uses a lower voltage, does anyone know?

- mikealdren

- Coveted Fifth Gear

- Posts: 1194

- Joined: 26 Aug 2006

Spyder have produced a control unit for the Mazda motor to slow it down and make it less aggressive. I would assume it uses a lower voltage, does anyone know?

- mikealdren

- Coveted Fifth Gear

- Posts: 1194

- Joined: 26 Aug 2006

19 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 13 guests