My Electronic Ignition & Injector TB Project

26 posts

• Page 1 of 2 • 1, 2

After very positive and good feedback of this thread:

elan-mods-f31/should-change-ecu-who-has-done-t37677.html

I decided to install an electronic ignition and injection system in my Elan Sprint. In this thread I would like to show how my design looks like, the parts I used, the cost (and problems) involved and maybe I encourage others ?

To complete the whole thing, it will certainly take me a while but I try to report here as I get along with new parts installed. First of all I will install ignition only, if that works fine I will add the injection part (semi-sequential).

By the way, all descriptions are given to my best knowledge and I appreciate feedback and corrections (my mother language is not English...).

There are few goals in this conversion:

1) Everything must be reversible to original condition without 'major' effort.

2) I want better cold & hot start, better fuel economy, wider torque range but same output power

3) All selected sensors and parts shall use when ever possible the AMP mini timer type of connector

(due to availability and price)

4) Because of limited access to tools and machines, I try to design as simple as possible, however

access to a lathe is required.

5) I try to keep parts cost as low as possible (but hopefully with common sense)

The ignition-only system is composed of the following main parts:

=================================================================

1 OMEX600 ECU and open end wire harness

1 Trigger wheel & sensor (Ford 36-1)

1 Throttle position sensor (I use the same type for DellOrto and Injector TBs)

1 Ignition coil pack (Ford Type A Connector)

1 Air temp sensor

1 Coolant temp sensor

1 Air pressure sensor (I live in a mountain area)

Adding Trigger wheel and sensor:

=================================

- Manufacture the parts according my drawings. Remove the crank shaft pulley and insert the spigot (which serves as crank shaft replacement).

- When drilling the hole for the splint pin, it is essential that the trigger wheel is absolutely centered to the pulley. At the head side of the pulley bolt/screw use duct tape to fill the gap between the trigger wheel center hole (12mm) and the bolt (7/16" 11mm). There should be no play.

- Put everything together and place the trigger wheel with the missing tooth at about 9 o'clock and the pulley TDC at about 2 o'clock. Drill a hole of 0.2mm under size of the splint pin into trigger wheel, shim and pulley in one go.

- Increase the hole in the trigger wheel and pulley to splint pin diameter size and press the pin into the shim (see pics). There shouldn't be any rotational movement between trigger wheel and pulley.

- the sensor bracket is designed to hold a sensor of about 38mm length with a gap of about 0.5mm to the trigger wheel.

elan-mods-f31/should-change-ecu-who-has-done-t37677.html

I decided to install an electronic ignition and injection system in my Elan Sprint. In this thread I would like to show how my design looks like, the parts I used, the cost (and problems) involved and maybe I encourage others ?

To complete the whole thing, it will certainly take me a while but I try to report here as I get along with new parts installed. First of all I will install ignition only, if that works fine I will add the injection part (semi-sequential).

By the way, all descriptions are given to my best knowledge and I appreciate feedback and corrections (my mother language is not English...).

There are few goals in this conversion:

1) Everything must be reversible to original condition without 'major' effort.

2) I want better cold & hot start, better fuel economy, wider torque range but same output power

3) All selected sensors and parts shall use when ever possible the AMP mini timer type of connector

(due to availability and price)

4) Because of limited access to tools and machines, I try to design as simple as possible, however

access to a lathe is required.

5) I try to keep parts cost as low as possible (but hopefully with common sense)

The ignition-only system is composed of the following main parts:

=================================================================

1 OMEX600 ECU and open end wire harness

1 Trigger wheel & sensor (Ford 36-1)

1 Throttle position sensor (I use the same type for DellOrto and Injector TBs)

1 Ignition coil pack (Ford Type A Connector)

1 Air temp sensor

1 Coolant temp sensor

1 Air pressure sensor (I live in a mountain area)

Adding Trigger wheel and sensor:

=================================

- Manufacture the parts according my drawings. Remove the crank shaft pulley and insert the spigot (which serves as crank shaft replacement).

- When drilling the hole for the splint pin, it is essential that the trigger wheel is absolutely centered to the pulley. At the head side of the pulley bolt/screw use duct tape to fill the gap between the trigger wheel center hole (12mm) and the bolt (7/16" 11mm). There should be no play.

- Put everything together and place the trigger wheel with the missing tooth at about 9 o'clock and the pulley TDC at about 2 o'clock. Drill a hole of 0.2mm under size of the splint pin into trigger wheel, shim and pulley in one go.

- Increase the hole in the trigger wheel and pulley to splint pin diameter size and press the pin into the shim (see pics). There shouldn't be any rotational movement between trigger wheel and pulley.

- the sensor bracket is designed to hold a sensor of about 38mm length with a gap of about 0.5mm to the trigger wheel.

Last edited by crypto on Thu Jul 20, 2017 7:06 pm, edited 2 times in total.

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

Your VR sensor bracket may be on the lightweight side as you want to avoid any vibration. I made the bracket from heavier steel and included a brace.

Dougal.

Dougal.

- dougal9887

- Third Gear

- Posts: 244

- Joined: 23 Aug 2013

dougal9887 wrote:Your VR sensor bracket may be on the lightweight side as you want to avoid any vibration...

Dougal.

You are right, I thought about this too. My concern was the movement of the sensor out of center of the trigger wheel (and not the movement closer to trigger wheel). This would cause a modulation of sensor amplitude. However, the logic in the ECU looks for the zero crossing of the sensor signal, and in practical use it has not caused any problems. The used aluminum is strong enough to lean on it.

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

Adding coolant temp sensor

==============================

mechanical drawing

and throttle position sensor:

=============================

==============================

mechanical drawing

and throttle position sensor:

=============================

Last edited by crypto on Sun Jul 23, 2017 9:27 pm, edited 1 time in total.

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

Dellorto TPS ?? or are you using converted Dellortos to hide the injectors ?

As for the Trigger wheel , why not mod the flywheel ?

John

As for the Trigger wheel , why not mod the flywheel ?

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

john.p.clegg wrote:Dellorto TPS ?? or are you using converted Dellortos to hide the injectors ?

As for the Trigger wheel , why not mod the flywheel ?

John

Hi John, no converted Dellortos

Regarding flywheel, that would have been simple (and very accurate) if Lotus had put the teeth on it initially

Cheers Peter

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

Peter,

From my experience of fitting EFI it is a good idea to get the car running on ECU ignition and carbs. But there is no need to map the ECU at this stage. You just need to set the ignition timing correctly with a map that is similar to the dizzy curve. Once the engine will start easily in this state you can then fit the injection with the knowledge that any problems are on the fuelling side.

Cheers

John

From my experience of fitting EFI it is a good idea to get the car running on ECU ignition and carbs. But there is no need to map the ECU at this stage. You just need to set the ignition timing correctly with a map that is similar to the dizzy curve. Once the engine will start easily in this state you can then fit the injection with the knowledge that any problems are on the fuelling side.

Cheers

John

- elanman999

- Fourth Gear

- Posts: 500

- Joined: 12 Nov 2005

John, what you are saying was exactly my intention. I started with a dizzy timing curve identical for all load conditions. My hope was to optimize ignition timing also for the carburetors by attaching a TPS sensor. This works but I "think" I observe knocking on high load, this even with the dizzy timing. I reduced the timing now and it has improved significantly.

I don't understand why it knocks with the dizzy timing, I use regular 95 octane fuel but with K&N filters instead of the original Lotus setup. In other words, air entering the carbs is significantly warmer. Should this matter ? I don't know and I'm currently reverting back to original to see if there's any difference.

My intention is to use a return-less fuel system, so I ordered copper fuel piping to replace the standard tube. But during internet research I found this : http://documents.msdperformance.com/2920_add.pdf

What puzzles me is this note: "... If you are planning to use metal tubing for your fuel system, then a fuel system with a return to the tank is recommended...." Unfortunately the article doesn't state why, any ideas ?

Currently I see two solutions:

1) a pulse-width regulated fuel pump, the pressure is electrically measured and the pump regulated accordingly

2) the pump runs full speed and a mechanical pressure regulator will feed overflow directly into the main tank.

In both cases there will be no pressure feedback from the manifold (the injectors differential fuel pressure will vary due to this) but I will use a Lambda sensor to compensate for.

Any comments ?

Cheers Peter

I don't understand why it knocks with the dizzy timing, I use regular 95 octane fuel but with K&N filters instead of the original Lotus setup. In other words, air entering the carbs is significantly warmer. Should this matter ? I don't know and I'm currently reverting back to original to see if there's any difference.

My intention is to use a return-less fuel system, so I ordered copper fuel piping to replace the standard tube. But during internet research I found this : http://documents.msdperformance.com/2920_add.pdf

What puzzles me is this note: "... If you are planning to use metal tubing for your fuel system, then a fuel system with a return to the tank is recommended...." Unfortunately the article doesn't state why, any ideas ?

Currently I see two solutions:

1) a pulse-width regulated fuel pump, the pressure is electrically measured and the pump regulated accordingly

2) the pump runs full speed and a mechanical pressure regulator will feed overflow directly into the main tank.

In both cases there will be no pressure feedback from the manifold (the injectors differential fuel pressure will vary due to this) but I will use a Lambda sensor to compensate for.

Any comments ?

Cheers Peter

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

Peter,

Yes you can use the TPS to great effect with carbs. But if you have the ign timing curve set to the dizzy curve and it pinks then I would double check your timing. With a TPS you can run more advance on light load and the retard the ignition when load is applied to avoid pinking. Pinking will also depend on CR and fuel used. On my +2 if running at 70mph in top the advance will be about 31 or 32 deg but as soon as the throttle is opened the ignition retards, if on full throttle to about 24 deg.

Fuel pump,

1, PWM of the pump is a good idea if you put your pressure sensor on the injector rail and have a good control system with feed forward from the TPS.

2, OEMs do use this method and it does work but it's bad in theory because you are controlling the pressure at the tank and not at the fuel rail. When you open the throttle the pressure at the rail will fall due to pressure drop along the pipe. Provided the engine is mapped with all the plumbing in it's final form then this pressure drop can be mapped around.

The other point about a returnless system is that IF any air or fuel vapour enters the pipe then the only place it can come out is at the injectors in the form of a miss-fire. Some OEMs have had issues with poor starting in very hot conditions because of this.

I do not run a returnless system and would not recommend it. OEMs do it to save money if you are going to the bother of installing EFI then do it right. Just MHO.

Cheers

John

Yes you can use the TPS to great effect with carbs. But if you have the ign timing curve set to the dizzy curve and it pinks then I would double check your timing. With a TPS you can run more advance on light load and the retard the ignition when load is applied to avoid pinking. Pinking will also depend on CR and fuel used. On my +2 if running at 70mph in top the advance will be about 31 or 32 deg but as soon as the throttle is opened the ignition retards, if on full throttle to about 24 deg.

Fuel pump,

1, PWM of the pump is a good idea if you put your pressure sensor on the injector rail and have a good control system with feed forward from the TPS.

2, OEMs do use this method and it does work but it's bad in theory because you are controlling the pressure at the tank and not at the fuel rail. When you open the throttle the pressure at the rail will fall due to pressure drop along the pipe. Provided the engine is mapped with all the plumbing in it's final form then this pressure drop can be mapped around.

The other point about a returnless system is that IF any air or fuel vapour enters the pipe then the only place it can come out is at the injectors in the form of a miss-fire. Some OEMs have had issues with poor starting in very hot conditions because of this.

I do not run a returnless system and would not recommend it. OEMs do it to save money if you are going to the bother of installing EFI then do it right. Just MHO.

Cheers

John

- elanman999

- Fourth Gear

- Posts: 500

- Joined: 12 Nov 2005

With everyone I talk to, they do not recommend to implement a returnless fuel system. Of course there are reasons why, but until now I found no one who tried it and said, it's impossible because of this or that. For me there is no right or wrong way to do an installation, because every solution has its advantages or disadvantages. As an engineer I always look at things and study how I could improve something without sacrificing the rest.

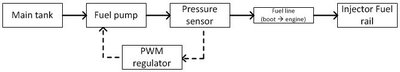

The first option of my setup would look like this:

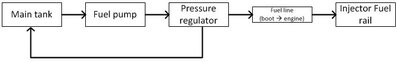

The second option would be:

There is no swirl pot/tank, no manifold pressure sensor but a lambda sensor. My next step will be the installation of a pressure sensor at the fuel rail to measure the time difference when pressure changes happen at the rail until the propagation of the change is sensed just after the pump. The calculated pressure drop from the pump to the rail should be less than 0.1 bar which is neglect able.

Yesterday was the first try to start the engine with the initial ECU mapping. After several unsuccessful attempts I started thinking what might be the problem. I checked voltages, cables and clicked around in the ECU software to possibly find a setting that I had overseen before. Then I gave it an other try and she started right away . I had to balance the bodies and adjust the fuel table to get a steady running but with help of the wideband lambda meter this was easy.

. I had to balance the bodies and adjust the fuel table to get a steady running but with help of the wideband lambda meter this was easy.

The first option of my setup would look like this:

The second option would be:

There is no swirl pot/tank, no manifold pressure sensor but a lambda sensor. My next step will be the installation of a pressure sensor at the fuel rail to measure the time difference when pressure changes happen at the rail until the propagation of the change is sensed just after the pump. The calculated pressure drop from the pump to the rail should be less than 0.1 bar which is neglect able.

Yesterday was the first try to start the engine with the initial ECU mapping. After several unsuccessful attempts I started thinking what might be the problem. I checked voltages, cables and clicked around in the ECU software to possibly find a setting that I had overseen before. Then I gave it an other try and she started right away

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

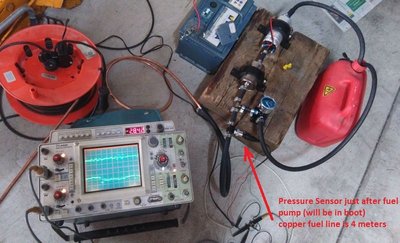

Time to tinker and some new information regarding the return-less fuel system. What you see her is actually option 2 from my post just above. I installed two pressure sensors, one after the pump (which will be in boot) and the other one at the end of the fuel rail. The goal is, to have the fuel pump pulse-width modulated/regulated based on the pressure I measure just after the pump, the end of the rail will be closed.

The question is, do I need to measure fuel-pressure at the rail or is it sufficient to get it after the pump ? To find out I measure the time delay of a pressure variation measured at the rail compared to one at the beginning of the fuel feed line (i.e. after the pump).

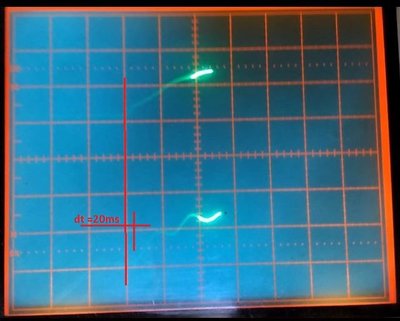

Difficult to see (and capture) but dT is less than 20msec. (top channel is after the pump, lower trace at rail end).

What you also see is the shock wave bouncing back and forth until it settles to about 3bar.

Sorry, this was maybe a little bit to technical. To shorten this, I'm confident to be able to control fuel pressure at the pump end without bigger impact on the system..

The question is, do I need to measure fuel-pressure at the rail or is it sufficient to get it after the pump ? To find out I measure the time delay of a pressure variation measured at the rail compared to one at the beginning of the fuel feed line (i.e. after the pump).

Difficult to see (and capture) but dT is less than 20msec. (top channel is after the pump, lower trace at rail end).

What you also see is the shock wave bouncing back and forth until it settles to about 3bar.

Sorry, this was maybe a little bit to technical. To shorten this, I'm confident to be able to control fuel pressure at the pump end without bigger impact on the system..

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

Sounds like you have the important stuff covered: little change in pressure between the sensor and injectors with variation in load (flow) and adequate time response for controllability. I see a few advantages to a return system (which I implemented on my injected Elan). First, in your system if you overpressurize, as you will on throttle closure before the pump control responds, the excess pressure cannot be relieved except by feeding excess fuel through the injectors (well, eventually it would bleed backward through the pump but I mean in on/off throttle transitions rather than prolonged shutdown). If your control is quick this probably isn't very significant, but it is a disadvantage. Also, I think flowing systems are more resistant to vaporlock issues (and I have a Renault 5 Turbo2 which means I am familiar with vaporlock). Again, probably not an issue as Elans don't run hot anyway.

I considered a returnless system as it wasn't convenient to plumb a return line and I don't like to see excess plumbing but I decided the ability to accurately manage injector pressure with a mechanical regulator of proven reliability in racing use was worth the extra work. I am running a fuel cell and had the body off the chassis anyway so running lines was not too difficult. TomR

I considered a returnless system as it wasn't convenient to plumb a return line and I don't like to see excess plumbing but I decided the ability to accurately manage injector pressure with a mechanical regulator of proven reliability in racing use was worth the extra work. I am running a fuel cell and had the body off the chassis anyway so running lines was not too difficult. TomR

- TomR

- Second Gear

- Posts: 116

- Joined: 19 Sep 2003

Hi Tom

Yes, you are quite right regarding the over pressure issue (or under pressure which I think is worse). Unfortunately I have no technical data about reaction times of mechanical valves, which would be used in place of my pressure control.

When I did these measurements, I also played with fuel pressure to see how the air/fuel ratio would change. At a pressure of :

3.5 bar -> 12.0 AFR

3.0 bar -> 12.3 AFR

2.5 bar -> 12.7 AFR

I know it's not 14.6 but just wanted to know how big the AFR changes are over a range of 1 bar.

The reason I want a return less system is the lack of holes for the return line plumbing. If it was an American version the chassis might have been prepared for this because they had a vapor collection system and an additional pipeline in the other edge of the chassis. My fuel pump doesn't get hot, so the fuel to the injectors is maybe a little warmer than ambient temperature. The question is how hot can it get in the rail during idle in hot summer ? Hmm...time will tell if this works.

Cheers, Peter

Yes, you are quite right regarding the over pressure issue (or under pressure which I think is worse). Unfortunately I have no technical data about reaction times of mechanical valves, which would be used in place of my pressure control.

When I did these measurements, I also played with fuel pressure to see how the air/fuel ratio would change. At a pressure of :

3.5 bar -> 12.0 AFR

3.0 bar -> 12.3 AFR

2.5 bar -> 12.7 AFR

I know it's not 14.6 but just wanted to know how big the AFR changes are over a range of 1 bar.

The reason I want a return less system is the lack of holes for the return line plumbing. If it was an American version the chassis might have been prepared for this because they had a vapor collection system and an additional pipeline in the other edge of the chassis. My fuel pump doesn't get hot, so the fuel to the injectors is maybe a little warmer than ambient temperature. The question is how hot can it get in the rail during idle in hot summer ? Hmm...time will tell if this works.

Cheers, Peter

The really good drivers have the bugs on the side windows (cit. Walter R?hrl)

-

crypto - Second Gear

- Posts: 105

- Joined: 20 Apr 2014

26 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 28 guests