Couple of photos before I put my engine in

16 posts

• Page 1 of 2 • 1, 2

Hi,

Just a couple of photos that might be useful to somebody.

This is how I mount the exhaust to the gearbox - got fed up with U clamps and those posh jubilee clips, they all seem to get ripped off.

I modified my TTR antiroll bar to use spherical joints so now it is one of the easily jobs and not the pain in the ass that it was.

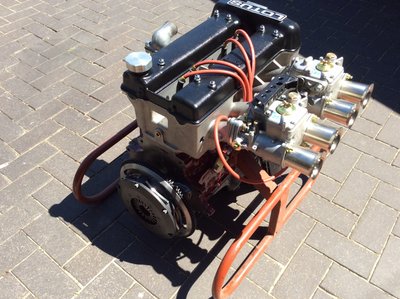

Nothing on the engine just wanted to take photos of it! - if I get chance I will take better photos before fitting.

Regards

Steve

Just a couple of photos that might be useful to somebody.

This is how I mount the exhaust to the gearbox - got fed up with U clamps and those posh jubilee clips, they all seem to get ripped off.

I modified my TTR antiroll bar to use spherical joints so now it is one of the easily jobs and not the pain in the ass that it was.

Nothing on the engine just wanted to take photos of it! - if I get chance I will take better photos before fitting.

Regards

Steve

- patrics

- Fourth Gear

- Posts: 534

- Joined: 21 Sep 2003

elanfan1 wrote:I?m far from an engineering buff but why would you want any movement in the roll bar transferred to your exhaust? Just going to loosen things isn?t it?

I believe these are two mechanically unrelated topics (wrapped in a single post)

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1998

- Joined: 02 Sep 2013

I'll be interested to hear whether the exhaust bracket suffers a fatigue failure in due course.

Does removal of all compliance in the antiroll bar create much 'noise'?

That's a very fancy looking clutch.

Does removal of all compliance in the antiroll bar create much 'noise'?

That's a very fancy looking clutch.

Last edited by MarkDa on Wed Jul 11, 2018 9:38 am, edited 1 time in total.

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

Re Ease of sway bar removal.

I solved the problem by having alloy D clamps made which use off the shelf "rubbers" and are clamped to the horizontal flange of the chassis. This results in a slightly stiffer effective bar and very easy removal when required.

Ultimately, I will have an inverted T bracket fabricated that will bolt to the chassis vertical as well as the horizontal. The inner part of the T will be drilled to offer alternative clamp positions so that I have a variety of stiffnesses available by moving 4 bolts.

Adjustable, easy to use and cheap.

Peter

I solved the problem by having alloy D clamps made which use off the shelf "rubbers" and are clamped to the horizontal flange of the chassis. This results in a slightly stiffer effective bar and very easy removal when required.

Ultimately, I will have an inverted T bracket fabricated that will bolt to the chassis vertical as well as the horizontal. The inner part of the T will be drilled to offer alternative clamp positions so that I have a variety of stiffnesses available by moving 4 bolts.

Adjustable, easy to use and cheap.

Peter

- cudabenefast

- First Gear

- Posts: 27

- Joined: 27 Nov 2015

I think the bar is supposed to twist along it's length and you've eliminated that motion; effectively making two short springs. I will guess it will crack at the weld. Let's hope I'm wrong. I hope you get back on to say how it went.

We are supposed to be having fun, are we not?

- USA64

- Third Gear

- Posts: 286

- Joined: 10 Dec 2017

"I don't see how clamping bar to chassis without longitudinal play will work given that the suspension moves vertically rather than in an arc."

Is it a perfect engineering solution - no!

Does it work? Yes it has worked just fine for 18 months and for nearly 50 years on Ford Escorts etc including on many Championship winning track and rally cars.

USA64 if you question is directed to me, my bar still twists along its length in poly bushes.

Cheers Peter

Is it a perfect engineering solution - no!

Does it work? Yes it has worked just fine for 18 months and for nearly 50 years on Ford Escorts etc including on many Championship winning track and rally cars.

USA64 if you question is directed to me, my bar still twists along its length in poly bushes.

Cheers Peter

- cudabenefast

- First Gear

- Posts: 27

- Joined: 27 Nov 2015

Peter

Escorts et al used McPherson struts not double wishbones.

The antiroll bar was the second part of the lower wishbone with connections into the lower track control arm and at the chassis, both of which were designed to take the significantly increased loads that their role required.

The geometry meant that the wheel travel was on an arc but not in conflict with any other element.

I can't help but think that Lotus would have opted for the cheaper and easier chassis bracket if it made no difference and didn't overstress the suspension.

As you say your set up is less than perfect geometrically and works by placing a side load through the trunnion stud and then flexing the wishbone bushes.

Each to their own of course and I hope it continues to function well and gives you 50 years of trouble free service.

Personally I find that removing the whole bar is easy enough - removing and replacing the link and bushes is of course a different matter.

Escorts et al used McPherson struts not double wishbones.

The antiroll bar was the second part of the lower wishbone with connections into the lower track control arm and at the chassis, both of which were designed to take the significantly increased loads that their role required.

The geometry meant that the wheel travel was on an arc but not in conflict with any other element.

I can't help but think that Lotus would have opted for the cheaper and easier chassis bracket if it made no difference and didn't overstress the suspension.

As you say your set up is less than perfect geometrically and works by placing a side load through the trunnion stud and then flexing the wishbone bushes.

Each to their own of course and I hope it continues to function well and gives you 50 years of trouble free service.

Personally I find that removing the whole bar is easy enough - removing and replacing the link and bushes is of course a different matter.

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

The stock bush can be pressed in to the link with a vice and the bushed link then slid over the sway-bar. The book said I couldn't but someone said you can he just did it. So I tried it; it was easy. Poly I don't know I'm not a racer.

We are supposed to be having fun, are we not?

- USA64

- Third Gear

- Posts: 286

- Joined: 10 Dec 2017

Peter

I've been thinking about your further development and am trying to understand how the adjustability will work.

Most of those I've seen have alternate pick up points at the wishbone end to vary the leverage applied to the bar thereby changing the stifness.

Mark

I've been thinking about your further development and am trying to understand how the adjustability will work.

Most of those I've seen have alternate pick up points at the wishbone end to vary the leverage applied to the bar thereby changing the stifness.

Mark

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

MarkDa wrote:I'll be interested to hear whether the exhaust bracket suffers a fatigue failure in due course.

Does removal of all compliance in the antiroll bar create much 'noise'?

That's a very fancy looking clutch.

The exhaust bracket has been on for a while now - it is lasting longer than all the normal arrangements!

The roll bar is not solid and I guess it can move more freely than standard - as for noise I wouldn?t know this is for racing

The clutch is from Helix - Obviously for racing

Regards

Steve

- patrics

- Fourth Gear

- Posts: 534

- Joined: 21 Sep 2003

16 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 13 guests