REAR STUB AXLE

10 posts

• Page 1 of 1

At a race last weekend I had the unpleasant experience of a left rear stub axle failing and thus becoming a 3 wheel Elan. The axle is a TT one and has failed at the end of the 'keyway' - a superb stress raiser!

Has anyone else had this problem?

The shafts have done about 20 races, and look as if they had good contact with the inside of the hub. Do we have to life them to 19 races?

I seem to remember that the first Elan I raced - 20 plus years ago, I used the normal Lotus stub axles and never had a failure - and that was on 10" wide slicks. The Lotus shaft has a long tapering out of the keyway, whist the TT stops abrubtly - and this is where it failed. Steel looks fine grained and as it should be for this spec, but a lovely example of a classic fatigue and with stress marks.

Needless to say the right and is now off the car and will be magnaflux tested tomorrow!

Richard

Has anyone else had this problem?

The shafts have done about 20 races, and look as if they had good contact with the inside of the hub. Do we have to life them to 19 races?

I seem to remember that the first Elan I raced - 20 plus years ago, I used the normal Lotus stub axles and never had a failure - and that was on 10" wide slicks. The Lotus shaft has a long tapering out of the keyway, whist the TT stops abrubtly - and this is where it failed. Steel looks fine grained and as it should be for this spec, but a lovely example of a classic fatigue and with stress marks.

Needless to say the right and is now off the car and will be magnaflux tested tomorrow!

Richard

- paros

- Second Gear

- Posts: 105

- Joined: 06 Nov 2003

there's no link buy the catalog for $5 or $6, Lots of good info in the catalog.

www.davebean.com

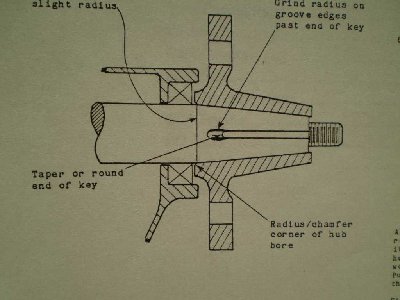

Heres a sample,

You will need to copy the text image and rotate it 90 degrees to the left.

www.davebean.com

Heres a sample,

You will need to copy the text image and rotate it 90 degrees to the left.

Last edited by garyeanderson on Sat Jun 30, 2007 2:58 pm, edited 1 time in total.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

First of all thank you all very much for the input.

Two things to add

One is that 3 times the left K O wheel has worked loose - this is a problem I found out after Anglesey race with the cast wheels not being thick enough for the KO to be tight. And of course the rear left is the one that gets all the reversals as you come on and off the power to steer. Hence why this one keps undoing the eared KO and the wheel working loose - and not sucha problem with the fronts or rear right. The loose wheel problem and the associated vibration had slackened off the stub axle nut that holds the hub in place - this has I am certain contributed to the problem. At one race 4 weeks ago I was seen using loctite to try and stop the rear left knock on, working loose.

I also found that if I had ordered the stub axles specifically for racing Tony Thompson would have offered his ' keyless' design. I am now ordering a pair of these. The Bean solution is the other way that Tony and I discussed earlier this week.

The point is of course that the key does not drive but locates and makes it easier to do the hub nut tight without the stub axle rotating.

The web site has raised awareness of peole to this potentail problem before someone got hurt Fortunately mine broke at the Mallory Hairpin exit and not Gerrards - which is top gear and the longest corner in the UK!

In conclusion it would seem that the Bean solution or the Tony T one of a keyless axle removes the danger.

Richard

Two things to add

One is that 3 times the left K O wheel has worked loose - this is a problem I found out after Anglesey race with the cast wheels not being thick enough for the KO to be tight. And of course the rear left is the one that gets all the reversals as you come on and off the power to steer. Hence why this one keps undoing the eared KO and the wheel working loose - and not sucha problem with the fronts or rear right. The loose wheel problem and the associated vibration had slackened off the stub axle nut that holds the hub in place - this has I am certain contributed to the problem. At one race 4 weeks ago I was seen using loctite to try and stop the rear left knock on, working loose.

I also found that if I had ordered the stub axles specifically for racing Tony Thompson would have offered his ' keyless' design. I am now ordering a pair of these. The Bean solution is the other way that Tony and I discussed earlier this week.

The point is of course that the key does not drive but locates and makes it easier to do the hub nut tight without the stub axle rotating.

The web site has raised awareness of peole to this potentail problem before someone got hurt Fortunately mine broke at the Mallory Hairpin exit and not Gerrards - which is top gear and the longest corner in the UK!

In conclusion it would seem that the Bean solution or the Tony T one of a keyless axle removes the danger.

Richard

- paros

- Second Gear

- Posts: 105

- Joined: 06 Nov 2003

The keyless axles from TT work well. However, it is imperative that the hubs are perfectly lapped in before tourquing up the nuts. Time spent here will pay off ! ( - had to renew one following own shortcut.....  )

)

Dag

Dag

Elan S1 -64/ Elan race-replica 26R / Works Escort TwinCam -69/ Brabham BT41 Holbay

-

Dag-Henning - Third Gear

- Posts: 330

- Joined: 30 Sep 2004

Thanks Dag

Yes I went and lapped them - in fact I had to buy more paste this morning! An hour a side with coffee breaks. Smashing blister on my hand to prove the hard work. Got 95% plus contact from the lapping - on both hubs a small hollow in middle of the taper.

having mentioned the probelms of wheels working loose, I have to say the nut was at around 100 plus ft lbs as it took a long tube with me standing on it to free the nut.

But I do intend to follow the advice and set it to 150 plus lb ft and then do a a lap and retorque.

A colleague in an F1 team says to heat the hub to 100/120 centrigrade and then install - then torque. Sounds easy in F1 speak but on an Elan not so easy!

Next race is at Snetterton - 6 hours away so not ideal for testing if there is a problem

Richard

Yes I went and lapped them - in fact I had to buy more paste this morning! An hour a side with coffee breaks. Smashing blister on my hand to prove the hard work. Got 95% plus contact from the lapping - on both hubs a small hollow in middle of the taper.

having mentioned the probelms of wheels working loose, I have to say the nut was at around 100 plus ft lbs as it took a long tube with me standing on it to free the nut.

But I do intend to follow the advice and set it to 150 plus lb ft and then do a a lap and retorque.

A colleague in an F1 team says to heat the hub to 100/120 centrigrade and then install - then torque. Sounds easy in F1 speak but on an Elan not so easy!

Next race is at Snetterton - 6 hours away so not ideal for testing if there is a problem

Richard

- paros

- Second Gear

- Posts: 105

- Joined: 06 Nov 2003

I have had a hub shaft similarly fail. The Elan is amazingly stable on 3 wheels I found. I lost the outside rear at around 120kph going into MG corner at Phillip island and had no problem driving the car off onto the grass to park it when the rear wheel went past me !!

I believe the orginal cast iron hubs can flex and the taper come loose under racing corner loads adding to the stresss at the end of the shaft around the key and causing the fatigue cracking even in high strength steel shafts. I now use high strength steel hubs also which fit more rigidly on the shafts.

cheers

Rohan

I believe the orginal cast iron hubs can flex and the taper come loose under racing corner loads adding to the stresss at the end of the shaft around the key and causing the fatigue cracking even in high strength steel shafts. I now use high strength steel hubs also which fit more rigidly on the shafts.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

10 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 28 guests