What on earth??

17 posts

• Page 1 of 2 • 1, 2

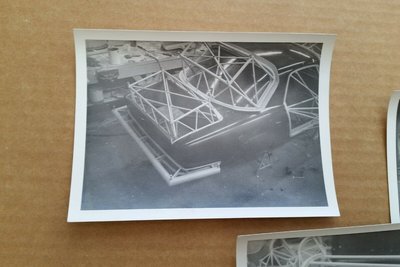

Paul has posted some more photos on eBay, this one is rather interesting

https://www.ebay.co.uk/itm/LOTUS-ELAN-C ... rk:16:pf:0

No connection to Paul, just a happy customer.

https://www.ebay.co.uk/itm/LOTUS-ELAN-C ... rk:16:pf:0

No connection to Paul, just a happy customer.

-

Mazzini - Coveted Fifth Gear

- Posts: 2282

- Joined: 11 Dec 2010

Interesting. I?ve seen lots of early factory photos and have never seen these gigs. It looks like they are placed on a painted body which doesn?t make a lot of sense. I would have thought they would have been ?measured? while still in raw fiberglass form.

Glen

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

05 Elise - Back where I started

65 Elan S2 - 26/4055

72 Europa - 74/2358R

69 Elan S4 - 45/7941

64 Elan S1 - 26/0379

12 Colin 30 - Lotus Racing Kart

07 Exige S - Wicked Road/Track Car

07 Exige S - Fast Road/Track Car

06 Elise - Track pack

-

Certified Lotus - Coveted Fifth Gear

- Posts: 1233

- Joined: 04 Aug 2014

gus wrote:perhaps they are display photos showing the use of the items

yes, it seems to me that they are the moulding jigs used to glue the different finishing parts to the body, like boot water chanel, door jambs... (e.g. to make sure the bonnet will fit and the seam area is smooth it makes sens to use a jig for registering seamlessly all the constituting parts) - these moulding jigs are nicely triangulated to stay rigid

new gel coat is smooth and shiny like paint

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2044

- Joined: 02 Sep 2013

I would think these jigs are parts of the main mold used to be attached to the main mold to create the details of window openings and bonnet aperature. Note there is a piece to mold the slide area in the front of the bonnet aperature. And then separate headlamp pod molds.

Roger

Roger

'67 Elan S3 SS DHC

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

- Elan45

- Coveted Fifth Gear

- Posts: 2518

- Joined: 23 Nov 2008

Lotus had multiple moulds on the go at any one time to get the production rate up which were made in sections from glassfibre reinforced with steel tubing and bolted together. There are pictures on the web of the moulds used by Lotus and by Bourne which look nothing like these frames.

The tooling in the picture looks as if it could have been used as formers to produce the parts of the moulds which couldn't be made by laying up over the original clay buck, not in the production of the final bodies themselves.

It would be very interesting to find out for sure.

Nice bit of 'Chapman spaceframe triangulation' on the support structures for the formers.

The tooling in the picture looks as if it could have been used as formers to produce the parts of the moulds which couldn't be made by laying up over the original clay buck, not in the production of the final bodies themselves.

It would be very interesting to find out for sure.

Nice bit of 'Chapman spaceframe triangulation' on the support structures for the formers.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1178

- Joined: 27 Mar 2011

Andy8421 wrote:Lotus had multiple moulds on the go at any one time to get the production rate up which were made in sections from glassfibre reinforced with steel tubing and bolted together. There are pictures on the web of the moulds used by Lotus and by Bourne which look nothing like these frames.

The tooling in the picture looks as if it could have been used as formers to produce the parts of the moulds which couldn't be made by laying up over the original clay buck, not in the production of the final bodies themselves.

It would be very interesting to find out for sure.

Nice bit of 'Chapman spaceframe triangulation' on the support structures for the formers.

To get the panel fit on the new type 36 right? That would make sense.

-

Mazzini - Coveted Fifth Gear

- Posts: 2282

- Joined: 11 Dec 2010

When making a mold you just make it in pieces from an original, it is not necessary to do it all at once.

You could then make a master and start cutting it up to make internal details. So you make a faux body from the clay derived mold and cut the headlight holes door apertures etc out with a saw, form the details there, then make master molds from that

These are not mold pieces, and the excessive triangulation must be due to dimensional stability so it must be some kind of quality gear

You could then make a master and start cutting it up to make internal details. So you make a faux body from the clay derived mold and cut the headlight holes door apertures etc out with a saw, form the details there, then make master molds from that

These are not mold pieces, and the excessive triangulation must be due to dimensional stability so it must be some kind of quality gear

- gus

- Fourth Gear

- Posts: 724

- Joined: 05 May 2011

When I first started reading/posting on lotusElan.net all those moons ago, there was a US thread about the dimensional differences between the left & right hand sides of the car, when measured from a centreline down the body. Let?s just say that the cars didn?t have an equal width.....

So control can only be up to a certain level of ?quality?

Regards

Richard

So control can only be up to a certain level of ?quality?

Regards

Richard

Richard

'72 Sprint

'72 Sprint

- richardcox_lotus

- Coveted Fifth Gear

- Posts: 1359

- Joined: 11 Jul 2004

rgh0 wrote:To me they look like jigs for checking and trimming the openings to the final dimensions after moulding and before fitting the glass or headlights or boot and bonnet

cheers

Rohan

this photo in particular made me think that the rain gutter or other small concave ends may have been glassed on the assembled body

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2044

- Joined: 02 Sep 2013

17 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 19 guests