26R balance bar setting

5 posts

• Page 1 of 1

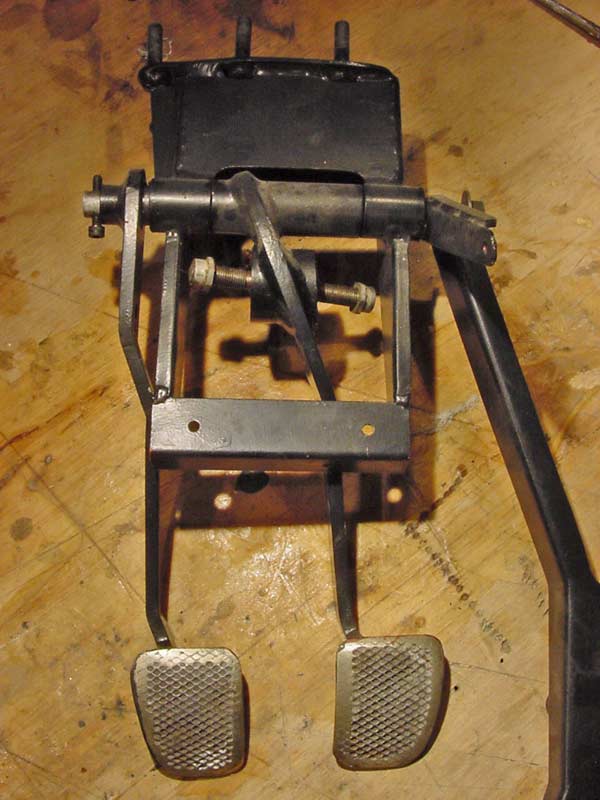

I'm starting from scratch as I had taken it all apart MANY years ago and have no record of the proportion of front to rear and would like to get it reasonably close as adjusting will be kind of tight down in the footwell. I'm also thinking of machining some flats on both ends to further facilitate the process. might not be needed if properly cleaned up and lubbed. Thoughts?

Jerry:

'61 S2 Elite | '69 S4 Elan FHC | '00 S1 Elise Sport 190

'61 S2 Elite | '69 S4 Elan FHC | '00 S1 Elise Sport 190

-

jabingb - Second Gear

- Posts: 174

- Joined: 22 Dec 2004

Too many variables to give a start point. Best is to make it easy to adjust and get to a safe place and do a bunch of threshold braking including some where you simulate initiating a turn and see what you like. The obvious thing would be to start with the spherical thing in the middle of the sleeve but cylinder sizes and caliper types can change that.

- Billmack

- Third Gear

- Posts: 257

- Joined: 30 Sep 2017

jabingb wrote:I'm starting from scratch as I had taken it all apart MANY years ago and have no record of the proportion of front to rear and would like to get it reasonably close as adjusting will be kind of tight down in the footwell. I'm also thinking of machining some flats on both ends to further facilitate the process. might not be needed if properly cleaned up and lubbed. Thoughts?

This setup looks nice, would you please post a photo of the complete system, possibly including a ruler for scale? I would just wonder about the sliding threaded rod dimension which seems a bit small on that view...

As for adjusting, assuming the car is set beforehand (reasonably driveable with current tires and pads etc), MerlinMotorsports, APRacing or Tilton offer a roadmap for tuning, which starts with the 2 clevis equally spaced on each side of the sphere (catching the play equally of both front and rear rods), and if there is a large discrepancy between front and rear caliper pistons, at an angle towards the rear for the front master cylinder side to accomodate for the larger volume to push, so at to get a sliding rod parallel to the pedal axis under load. Then when the sliding rod is set so that the leverage is larger on one side than the other, the applied braking pressure will be higher on the side (front or rear) with the shorter part of the sliding rod.

They also remind that when bleeding one should to open a caliper of the front and rear circuits at the same time (to avoid bending the sliding rod).

https://www.merlinmotorsport.co.uk/files/transfer/technical/doc/tilton600seriesbalancebars.pdf

Rohan posted a photo of a similar system some years ago

https://lotuselan.net/forums/viewtopic.php?f=12&t=17529&start=

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

I found the Merlin advice very useful.

https://www.merlinmotorsport.co.uk/p/ti ... able-72-50

With the spherical in the middle and the clevises set as per the advice I set my front M/C push rod 4mm longer than the rear. (Smaller front M/C)

I use a Tilton balance bar adjuster

https://www.merlinmotorsport.co.uk/p/ti ... able-72-50

and have found that a couple of clicks to the rear have been needed. I suspect one more click to the rear may be right but am still playing with that thought.

https://www.merlinmotorsport.co.uk/p/ti ... able-72-50

With the spherical in the middle and the clevises set as per the advice I set my front M/C push rod 4mm longer than the rear. (Smaller front M/C)

I use a Tilton balance bar adjuster

https://www.merlinmotorsport.co.uk/p/ti ... able-72-50

and have found that a couple of clicks to the rear have been needed. I suspect one more click to the rear may be right but am still playing with that thought.

Graeme

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

-

661 - Coveted Fifth Gear

- Posts: 1198

- Joined: 29 Mar 2012

I found bias so strong to the front I spaced the pushrods a bit further apart with washers on the balance screw. On further adjustment, I think I could have done without those, but the setup balances nicely as is, so I am reluctant to climb under there yet again and then re-set the balance. Oh, I'll do it some time as it does bother me a bit.

Incidental to this is that my 26R style box for LHD would develop terrific binding binding of the throttle axle on braking or clutching. The reason is that the throttle axle passes through the other pedal bearings and is returned by tiny springs that cannot compete with ordinary friction from the bearings under load. It's rather disconcerting to clutch and have that pedal then advance the throttle with no engine load! Weeks of fiddling led to mounting the throttle pedal on its own bearing. Works a treat now. John

Incidental to this is that my 26R style box for LHD would develop terrific binding binding of the throttle axle on braking or clutching. The reason is that the throttle axle passes through the other pedal bearings and is returned by tiny springs that cannot compete with ordinary friction from the bearings under load. It's rather disconcerting to clutch and have that pedal then advance the throttle with no engine load! Weeks of fiddling led to mounting the throttle pedal on its own bearing. Works a treat now. John

- baileyman

- Third Gear

- Posts: 347

- Joined: 17 Aug 2017

5 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 23 guests