Tightening Spinners

Hi

I have a 1971 Elan and I am doing a track day next weekend

To make sure my wheels stay on before, during and after I have purchased one of those wheel widget things

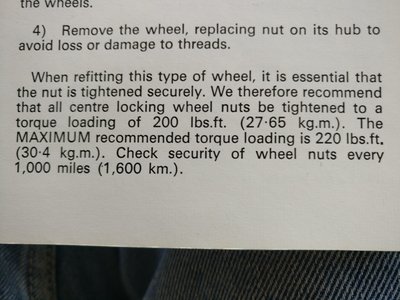

So my question is what setting do I need to set the torque wrench at? I've only had the car for a month and I'm new to all things Elan!

Many thanks

I have a 1971 Elan and I am doing a track day next weekend

To make sure my wheels stay on before, during and after I have purchased one of those wheel widget things

So my question is what setting do I need to set the torque wrench at? I've only had the car for a month and I'm new to all things Elan!

Many thanks