Another rear suspension thread!

19 posts

• Page 1 of 2 • 1, 2

I just got a pair of rear struts which I intend to strip and restore. (And eventually fit.)

I've been through the archives and been thoroughly discouraged!

Hub Puller - SJSportcars sell one that looks a bit limited and presumably only one side ? https://www.sjsportscars.com/parts-and- ... 6D0007.htm

Anyone have experience or know of a better?

Any particular tricks for shaft removal other than heat and a large hammer?

I've been through the archives and been thoroughly discouraged!

Hub Puller - SJSportcars sell one that looks a bit limited and presumably only one side ? https://www.sjsportscars.com/parts-and- ... 6D0007.htm

Anyone have experience or know of a better?

Any particular tricks for shaft removal other than heat and a large hammer?

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

JonB wrote:I believe that the SJS puller goes under a spinner. It's just a spacer with an adjustable width. Correct me if I'm wrong! But if so, I would not want to try and torque up that little grub screw to the required value for pulling a hub.

Appologies if I'm being thick but, if it is under the spinner, presumably the grub screw doesn't actually pull the hub?

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

I have a Sykes pickavant hydraulic puller, and two collars which screw onto the hub. I have removed mine several times, and also those of others without any trouble. I am sure a decent tool hire outfit would be able to supply one for little money.

Chris

Chris

- Chris

- Second Gear

- Posts: 93

- Joined: 06 Aug 2013

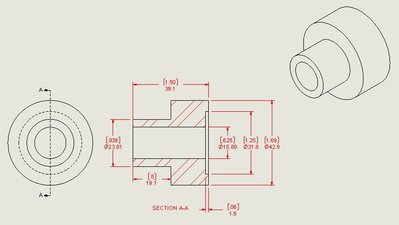

I made up one of the tools below. Not much to it, should be cheap to have made. Just slip it over the stub shaft with the nut removed and crank the K/O nut back on. The recess on the right in the cross section prevents the nut center from taking the load. I used a propane torch to warm the hub to help things along.

Scott

45/9011

Hawkestone, On, Ca

45/9011

Hawkestone, On, Ca

- snowyelan

- Third Gear

- Posts: 444

- Joined: 14 Sep 2003

A local member Paul Toombs helped remove mine with the handed hub extractors , no heat needed and after nearly 50 years they popped straight off. You do need a press for the bearings as well

I?m not sure about putting a spacer under the spinner , might it damage the spinner ?

Steve

I?m not sure about putting a spacer under the spinner , might it damage the spinner ?

Steve

- Concrete-crusher

- Third Gear

- Posts: 386

- Joined: 09 Jun 2013

Vince. Do not use a hub puller !!!!!!!!!!!!!!!

The hub removal tool works perfectly and surprisingly very affectively .

Take the retaining nut off the wheel output shaft , place the tool within the centre of the hub , adjust the grub screw, replace the spinner and hand tighten .

I then personally use a simple blow lamp to apply general heat directly to the back of the cast wheel hub ( not the bearings , or aluminium upright ) .

NOTE . You are not attempting to get the hub 'red' hot but hot enough that you are unable to touch .

Leave for 10-20 seconds to allow the heat to do its stuff then set about the wheel spinner tightening it up with a heavy copper mallet and within half a dozen blows the hub comes off , every time.

DO NOT have your face / body parts in front of the hub just in case the hub leaves the output shaft with considerable force.

I can see your issue being that the uprights are not connected to the car so will need securing some how some where otherwise you will find yourself beating the uprights around the garage floor.

Vince ,again . Do not use a hub puller you will wreck the hub and cause yourself serious physical injury if / when the hub puller comes off the hub.

The hub removal tool works perfectly and surprisingly very affectively .

Take the retaining nut off the wheel output shaft , place the tool within the centre of the hub , adjust the grub screw, replace the spinner and hand tighten .

I then personally use a simple blow lamp to apply general heat directly to the back of the cast wheel hub ( not the bearings , or aluminium upright ) .

NOTE . You are not attempting to get the hub 'red' hot but hot enough that you are unable to touch .

Leave for 10-20 seconds to allow the heat to do its stuff then set about the wheel spinner tightening it up with a heavy copper mallet and within half a dozen blows the hub comes off , every time.

DO NOT have your face / body parts in front of the hub just in case the hub leaves the output shaft with considerable force.

I can see your issue being that the uprights are not connected to the car so will need securing some how some where otherwise you will find yourself beating the uprights around the garage floor.

Vince ,again . Do not use a hub puller you will wreck the hub and cause yourself serious physical injury if / when the hub puller comes off the hub.

- greg40green

- Second Gear

- Posts: 214

- Joined: 02 Dec 2007

Elan Knock-On Hub Removal Tool

Remove Elan rear KO hubs with this specially designed tool and eliminate chances of bending or breaking your rear hubs. This tool threads directly onto the hub while the center bolt presses on the end of the axle shaft. One tool works for both RH and LH hubs!

Ref. 36T0286HD KO Hub Extractor - $125.

rd enterprises

I've used it. It works great. Had strut on bench with an electric torque gun, no problem.

Remove Elan rear KO hubs with this specially designed tool and eliminate chances of bending or breaking your rear hubs. This tool threads directly onto the hub while the center bolt presses on the end of the axle shaft. One tool works for both RH and LH hubs!

Ref. 36T0286HD KO Hub Extractor - $125.

rd enterprises

I've used it. It works great. Had strut on bench with an electric torque gun, no problem.

We are supposed to be having fun, are we not?

- USA64

- Third Gear

- Posts: 286

- Joined: 10 Dec 2017

I used one of these from Kelsport , worked well but expensive.

https://kelvedonlotus.co.uk/product/rear-hub-puller/

regards

Andy

https://kelvedonlotus.co.uk/product/rear-hub-puller/

regards

Andy

- batfish

- Third Gear

- Posts: 301

- Joined: 09 Oct 2003

Many thanks for the replies I shall respond individually a bit later.

Meanwhile I'm thinking of having a puller made - what is the thread size of the hub? I saw it mentioned in another thread and cannot find it now.

There is no immediate rush I have lots of other things to do!!

Meanwhile I'm thinking of having a puller made - what is the thread size of the hub? I saw it mentioned in another thread and cannot find it now.

There is no immediate rush I have lots of other things to do!!

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

There's another way to warm the hub:

Fit the K/O hub Remover with a mild tension on the bolt / or spacer/spinner set up. Preheat some Water to about 80 deg C and position the hub/shaft end upright. Slowly fill the five little pools evenly with the hot water. In my case, a pair of hubs sitting there for 50 years, refusing to come off with regular K/O puller and really heavy duty thrust bolt and 3feet 3/4 breaker bar, came off gently without noise or jumping around. Even the original paint stayed untouched. It would have been a good idea to fit a little plastic collar under the hub - to avoid water entering bearings.

Next Time...

PS the pair of handcrafted pullers I used had two flats machined to accept a huge spanner to counterbalance the torque.

Anna

Fit the K/O hub Remover with a mild tension on the bolt / or spacer/spinner set up. Preheat some Water to about 80 deg C and position the hub/shaft end upright. Slowly fill the five little pools evenly with the hot water. In my case, a pair of hubs sitting there for 50 years, refusing to come off with regular K/O puller and really heavy duty thrust bolt and 3feet 3/4 breaker bar, came off gently without noise or jumping around. Even the original paint stayed untouched. It would have been a good idea to fit a little plastic collar under the hub - to avoid water entering bearings.

Next Time...

PS the pair of handcrafted pullers I used had two flats machined to accept a huge spanner to counterbalance the torque.

Anna

1965 S2

- Emma-Knight

- Third Gear

- Posts: 362

- Joined: 26 Mar 2004

elanfan1 wrote:Surely there?s a member close enough to Vince to loan him a puller?? I believe he?s near High Wycombe.

I'm near High Wycombe and I have one of the SJ type removal tools (although it's a bit battered) that's taken my hubs off three or four times. Vince is welcome to borrow it but, even with heat, using it does feel like a good way to convert functional parts into scrap.

Re the grub screw, I've always assumed it's just to ensure the end of the shaft doesn't get damaged.

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

Emma-Knight wrote:There's another way to warm the hub:

Fit the K/O hub Remover with a mild tension on the bolt / or spacer/spinner set up. Preheat some Water to about 80 deg C and position the hub/shaft end upright. Slowly fill the five little pools evenly with the hot water. In my case, a pair of hubs sitting there for 50 years, refusing to come off with regular K/O puller and really heavy duty thrust bolt and 3feet 3/4 breaker bar, came off gently without noise or jumping around. Even the original paint stayed untouched. It would have been a good idea to fit a little plastic collar under the hub - to avoid water entering bearings.

Next Time...

PS the pair of handcrafted pullers I used had two flats machined to accept a huge spanner to counterbalance the torque.

Anna

Welcome back Anna ! It?s been a while. Do you still have your lovely S2 ?

Richard

'72 Sprint

'72 Sprint

- richardcox_lotus

- Coveted Fifth Gear

- Posts: 1098

- Joined: 11 Jul 2004

USA64 wrote:Ref. 36T0286HD KO Hub Extractor - $125.

rd enterprises

I've used it. It works great. Had strut on bench with an electric torque gun, no problem.

I agree this is a very good tool and similar ones are available from other sources. My preferred use is to slack the hub retaining nut off about one turn, install the removal tool, run the jacking screw in to about 80 ft-lb torque, finally strike the hex head of the jacking screw with a lead or copper mallet, straight in line with the axis of the jacking screw. This will pop the hub off of the tapered axle and nothing will fly very far. In my youth I tried this on an Aston Martin. We made two mistakes, removing the hub retaining nut completely and using the jacking screw to apply all of the force (i.e. not gently torquing the jacking screw and striking with a mallet). When the hub came off the taper it released enough stored energy to fly across the garage. Luckily nobody was hit by it.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

19 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 15 guests