Fuel pump leaking

21 posts

• Page 2 of 2 • 1, 2

For information the jacking point grommet from an MG Midget fits the hole, you have to partially trim some of it's 'ears' off for a good fit but it does work. Fit it from inside the car.

Moss Europe part number 2H8198, Moss USA part number 282-135

https://www.moss-europe.co.uk/grommet-j ... soc=139311

Moss Europe part number 2H8198, Moss USA part number 282-135

https://www.moss-europe.co.uk/grommet-j ... soc=139311

Mike

72 Sprint DHC

72 Sprint DHC

-

lotusfan - Third Gear

- Posts: 366

- Joined: 15 Sep 2003

ericbushby wrote:Hi Elanner

It is a few years ago now so I do not remember the details.

I suspect it involved removing the engine mounts and supporting the sump on a jack. The engine will not move far to the left but a bit more up and down.

It was an all metal pump which was replaced with another metal one. The carburettors had to come off I know.

I also have a bad habit of cutting spanners to fit the space available. I am gathering quite a collection of short, bent and ground down tools. I buy tools at car fairs and boot fairs if they are good quality and very cheap.

Best of luck.

Eric in Burnley

I think that was for the OIL pump, not the fuel pump.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Hi Bill

Yes, I think you are right there. I have done both with the engine in and it is a while back.

Cheers

Eric

Yes, I think you are right there. I have done both with the engine in and it is a while back.

Cheers

Eric

- ericbushby

- Coveted Fifth Gear

- Posts: 1353

- Joined: 13 Jun 2011

lotusfan wrote:For information the jacking point grommet from an MG Midget fits the hole, you have to partially trim some of it's 'ears' off for a good fit but it does work. Fit it from inside the car.

Moss Europe part number 2H8198, Moss USA part number 282-135

https://www.moss-europe.co.uk/grommet-j ... soc=139311

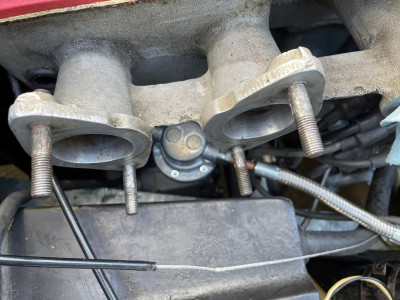

This is/was my original plug:

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3187

- Joined: 15 Sep 2010

Well, I finally had to remove my original glass bowl fuel pump to fix my Elan's poor running. Much to my surprise it came out quite easily without any need for a hole in the footwell despite the clearance being almost non-existent. Not more than 1/16", so close that there were slight marks showing that it had been rubbing lightly against the fiberglass. I think that, fortuitously, the jackshaft cam must have been well out of the way.

Anyway, after removal the unthinking test is to blow & suck on the inlet port of the pump to see if air will go one way but not the other. But this is no test at all. When blowing it's obvious that both valves in the pump need to open. But when sucking only one of the valves needs to close. So the pump must be taken apart and the two valves tested individually. Typically, one will be sticking open.

I decided that I would change both valves and, after pharriso provided some encouragement, I found that a small drill can be used to relieve the staking around the valves so that they can be removed without too much difficulty. Re-staking new valves with a screwdriver and hammer is also not difficult - the aluminium is soft. However, having successfully replaced one of the valves the other broke in half as soon as I *gently* tamped it home into the pump housing around the edges. (I was using a fuel pump refurbish kit purchased some years ago from a UK Elan parts supplier.)

At this point I was stuck with either getting a second refurbish kit or abandoning the whole idea and getting a new pump. I decided that a new pump was the safer option - pumps are hard enough to change without needing to do it twice due to poor quality valves. So, cautionary tale, check the quality of replacement valves carefully.

R.D. Enterprises supplies a replacement mechanical pump that is not the same as the original glass-bowl type but uses exactly the same fittings, so no changes are needed to the fuel lines. It turns out to be a neat little item and, being smaller, there's plenty of space between it and the footwell bodywork. However, it does not have a built-in filter so I also fitted an inline fuel filter in the boot.

It's amazing how much better the engine runs when the Weber float chambers are full!

Next time I suppose I'll switch to an electric pump.

Nick

Anyway, after removal the unthinking test is to blow & suck on the inlet port of the pump to see if air will go one way but not the other. But this is no test at all. When blowing it's obvious that both valves in the pump need to open. But when sucking only one of the valves needs to close. So the pump must be taken apart and the two valves tested individually. Typically, one will be sticking open.

I decided that I would change both valves and, after pharriso provided some encouragement, I found that a small drill can be used to relieve the staking around the valves so that they can be removed without too much difficulty. Re-staking new valves with a screwdriver and hammer is also not difficult - the aluminium is soft. However, having successfully replaced one of the valves the other broke in half as soon as I *gently* tamped it home into the pump housing around the edges. (I was using a fuel pump refurbish kit purchased some years ago from a UK Elan parts supplier.)

At this point I was stuck with either getting a second refurbish kit or abandoning the whole idea and getting a new pump. I decided that a new pump was the safer option - pumps are hard enough to change without needing to do it twice due to poor quality valves. So, cautionary tale, check the quality of replacement valves carefully.

R.D. Enterprises supplies a replacement mechanical pump that is not the same as the original glass-bowl type but uses exactly the same fittings, so no changes are needed to the fuel lines. It turns out to be a neat little item and, being smaller, there's plenty of space between it and the footwell bodywork. However, it does not have a built-in filter so I also fitted an inline fuel filter in the boot.

It's amazing how much better the engine runs when the Weber float chambers are full!

Next time I suppose I'll switch to an electric pump.

Nick

-

elanner - Fourth Gear

- Posts: 546

- Joined: 14 Sep 2010

21 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 21 guests