Weber Fuel Hoses

11 posts

• Page 1 of 1

Hi,

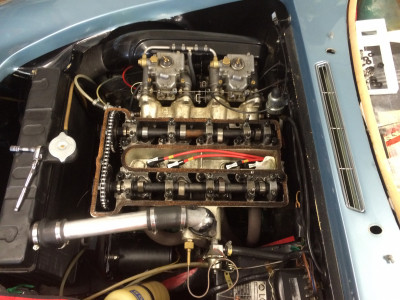

What do members consider to be the pros and cons for the original braided 'Y' hose that goes to the Webers from beneath, versus hoses that go in above the carbs via a tee banjo at the front carb and through a short hose to a banjo at the rear carb? My own thoughts are that any fuel leaks on the 'Y' version would not be immediately apparent, being hidden under the carbs. Are there any other reasons why some prefer the above carb hoses?

I intend to use a Huco 133010 pump, located in the engine bay.

Cheers

Mike

What do members consider to be the pros and cons for the original braided 'Y' hose that goes to the Webers from beneath, versus hoses that go in above the carbs via a tee banjo at the front carb and through a short hose to a banjo at the rear carb? My own thoughts are that any fuel leaks on the 'Y' version would not be immediately apparent, being hidden under the carbs. Are there any other reasons why some prefer the above carb hoses?

I intend to use a Huco 133010 pump, located in the engine bay.

Cheers

Mike

Mike

1967 S3 FHC

1968 S4 FHC

1967 S3 FHC

1968 S4 FHC

- smo17003

- Third Gear

- Posts: 394

- Joined: 11 May 2006

Personally I avoid the pre made hoses as it's hard to know the quality of the hose. Espicially if they are braided hoses.

In the age of ethernol fuels care needs to be taken with the grade of hose used to make sure it is safe and won't break down.

So personally I use the tee's and make my own lines, that way I can use a good quality correct grade hose. I also place the hose in heat shield tube for extra protection should there be a fire in the engine bay.

In the age of ethernol fuels care needs to be taken with the grade of hose used to make sure it is safe and won't break down.

So personally I use the tee's and make my own lines, that way I can use a good quality correct grade hose. I also place the hose in heat shield tube for extra protection should there be a fire in the engine bay.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

I have had 2 of the pre-made Ys fail recently, with fuel squirting out between the braiding. I have replaced all the rubber fuel hoses in my Elan with new piping.

In this age of dodgy suppliers I had to search for quality hoses - you want to look for hoses that meet SAE J30 R9 specification. This is specifically designed for fuels with added ethanol. I went with Codan hoses from the 'Hosemaster', not cheap but of good quality.

https://www.thehosemaster.co.uk/r9-unleaded-petrol-diesel-ethanol-automotive-fuel-hose/?gclid=EAIaIQobChMIm8-ij8T59gIVje7tCh38bAGKEAQYAiABEgLd2vD_BwE

I salvaged the T and the fittings from my Y pipe and used them with the new hose.

It only seemed to be Dell'Orto carbs on the Elan that ran the pipe above the carbs with a T fitting. All the webers I have seen used the Y pipe under the carb. I plan to move to the high pipe solution for my webers (I have bought the fittings) but the pipe will foul the aftermarket throttle linkage I have fitted so I need to do some fiddling about first.

In this age of dodgy suppliers I had to search for quality hoses - you want to look for hoses that meet SAE J30 R9 specification. This is specifically designed for fuels with added ethanol. I went with Codan hoses from the 'Hosemaster', not cheap but of good quality.

https://www.thehosemaster.co.uk/r9-unleaded-petrol-diesel-ethanol-automotive-fuel-hose/?gclid=EAIaIQobChMIm8-ij8T59gIVje7tCh38bAGKEAQYAiABEgLd2vD_BwE

I salvaged the T and the fittings from my Y pipe and used them with the new hose.

It only seemed to be Dell'Orto carbs on the Elan that ran the pipe above the carbs with a T fitting. All the webers I have seen used the Y pipe under the carb. I plan to move to the high pipe solution for my webers (I have bought the fittings) but the pipe will foul the aftermarket throttle linkage I have fitted so I need to do some fiddling about first.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1227

- Joined: 27 Mar 2011

Same here, I had a braided one fail, they're poor. I prefer to see the rubber., and know what I'm dealing with.

Current :- Elan S3 DHC SE S/S 1968,

1963 Alfa Giulia Ti Super Rep.

Previous :-

Elan S3 DHC SE SS 1968,

Elan S3 DHC S/E 1966

Elan S3 FHC Pre-Airflow 1966

1963 Alfa Giulia Ti Super Rep.

Previous :-

Elan S3 DHC SE SS 1968,

Elan S3 DHC S/E 1966

Elan S3 FHC Pre-Airflow 1966

- elans3

- Fourth Gear

- Posts: 528

- Joined: 12 Sep 2003

I read somewhere that the connection to the carb’s should be the high point as to avoid possible vapour locks. If you make your own ‘ Y ‘ type be careful with the ID as the difference between metric and imperial is small under these essentially push on seal is important.

- Craven

- Coveted Fifth Gear

- Posts: 1624

- Joined: 14 Sep 2013

Mike,

I know this is a bit off topic but you mentioned the Huco 133010 pump. I have come to the same conclusion for my Elan S4 with Dellortos. Last week I contacted a couple of well known suppliers to buy one. They both said they are not selling the low pressure version right now. Eorcarb said this model was pushing out too much pressure. They have told the manufacturer. It might not affect your pump as it could be a batch issue. Where in the engine bay do you intend to position the pump.

I know this is a bit off topic but you mentioned the Huco 133010 pump. I have come to the same conclusion for my Elan S4 with Dellortos. Last week I contacted a couple of well known suppliers to buy one. They both said they are not selling the low pressure version right now. Eorcarb said this model was pushing out too much pressure. They have told the manufacturer. It might not affect your pump as it could be a batch issue. Where in the engine bay do you intend to position the pump.

- RAJ2628

- Second Gear

- Posts: 74

- Joined: 24 Oct 2019

RAJ2628 wrote:Mike,

I know this is a bit off topic but you mentioned the Huco 133010 pump. I have come to the same conclusion for my Elan S4 with Dellortos. Last week I contacted a couple of well known suppliers to buy one. They both said they are not selling the low pressure version right now. Eorcarb said this model was pushing out too much pressure. They have told the manufacturer. It might not affect your pump as it could be a batch issue. Where in the engine bay do you intend to position the pump.

I've had the pump for about 12 months now, so hopefully it's OK, but I will bear in mind the pressure issue and probably plumb it into a gauge before fitting - thank you.

Not sure where I will locate it yet. I'm putting the coil on one of Cliveyboy's brackets, just behind the radiator, so possibly somewhere nearby i.e. where I can see it. Problem is my body has been away for new front and repaint for a while now. Until I get it back and on the chassis I'd just be guessing.

Mike

Mike

1967 S3 FHC

1968 S4 FHC

1967 S3 FHC

1968 S4 FHC

- smo17003

- Third Gear

- Posts: 394

- Joined: 11 May 2006

Thank you all. I'll probably ditch the Y hose and use some R9.

I also found this link quite useful in explaining hose specifications.

http://www.volksbolts.com/faq/fuelhose.htm

I also found this link quite useful in explaining hose specifications.

http://www.volksbolts.com/faq/fuelhose.htm

Mike

1967 S3 FHC

1968 S4 FHC

1967 S3 FHC

1968 S4 FHC

- smo17003

- Third Gear

- Posts: 394

- Joined: 11 May 2006

mbell wrote:Personally I avoid the pre made hoses as it's hard to know the quality of the hose. Espicially if they are braided hoses.

Agree 100%. With the introduction of E10 I decided to replace the hoses on the Elan's original style braided rubber with modern R9 fuel injection hose.

I'll admit I used the original fittings & configuration but the big lesson was the condition of the braided hoses.

Firstly the wall thickness was much thinner than what's considered normal these days or even what I expected it to be. Ok, pressure is nothing like fuel injection and in fairness it's never leaked, but the addition of wall thickness does give better resistance to permeation even if the mechanical strength is overkill on our cars.

Secondly I'd been getting roughly 2/3 of the pipe bore because the crimped fittings had collapsed the steel unions badly. And the rubber under the crimped ends was actually quite scary, no wonder we've had car fires in the past.

Until then I'd have sworn that OEM braided hoses was the best option. Now ? I want to see what the rubber looks like.....

Brian

-

UAB807F - Fourth Gear

- Posts: 604

- Joined: 20 Dec 2010

Brian,

I entirely agree. I leaned this lesson with a braided hose on my oil fired central heating boiler which failed when less than one year old. Having removed the braid the rubber was visibly cracked and had no visible spec printed on it. I have concluded that braid can be used as a disguise. This reminds me of my time in the inspection dept of a branch of GEC, if the chief inspector visited a fabricator and the fabrication had been painted he refused to carry out the inspection with the comment that a coat of paint may conceal errors.

Richard Hawkins

I entirely agree. I leaned this lesson with a braided hose on my oil fired central heating boiler which failed when less than one year old. Having removed the braid the rubber was visibly cracked and had no visible spec printed on it. I have concluded that braid can be used as a disguise. This reminds me of my time in the inspection dept of a branch of GEC, if the chief inspector visited a fabricator and the fabrication had been painted he refused to carry out the inspection with the comment that a coat of paint may conceal errors.

Richard Hawkins

- RichardHawkins

- Coveted Fifth Gear

- Posts: 1276

- Joined: 05 Jul 2008

11 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 11 guests