Page 5 of 6

Re: My first engine rebuild

Posted:

Fri Jan 12, 2018 6:25 pmby Concrete-crusher

Some progress , I have put the head on after setting TDC on the degree wheel , I opted for silicone on the cork front cover gasket and nothing on the head gasket. Oh and silicone on the rubber breather , all torqued down , it's quite tricky getting the D washer on the two ends to line up correctly.

I made a paper gasket for the chain tensioner and pivot both with wellseal on each side.

I found the head line up easily on the two guide bolts , despite the chain guide sticking up , next job is to swap a few shims and fit and time the cams.

Steve

Re: My first engine rebuild

Posted:

Thu Jan 18, 2018 1:39 pmby Concrete-crusher

So valve clearances done , valve timing done , sump on , rocker cover on

I opted for a new canister type oil pump , it did not feel quite as smooth as the original ford type but I put this down to new parts and no oil.

I have filled the filter with oil and run a little oil through it before assembly.

I have filled the engine with 4 litres of oil , and was expecting to see some oil emerge from the oil pressure hole when turning the engine by hand. It doesn't. Should I just wait until it's in the car and turning on the starter or should I pack the pump with grease or vasalene while it's easy to get too.

Steve

Re: My first engine rebuild

Posted:

Thu Jan 18, 2018 3:13 pmby MarkDa

Vaseline or engine assembly paste to get initial suction.

You'll be spinning the engine pretty fas without plugs to circulate oil before firing up anyway so that should build up full pressure on the gauge.

Re: My first engine rebuild

Posted:

Thu Jan 18, 2018 7:35 pmby mbell

I normally connect a garden weed killer spray bottle with oil in it to the oil pressure take off and prime the system that way. My engine never wants to build pressure on the starter until its running so I tend to prime it when I've done things like valve clearance and had the engine out for a while.

Re: My first engine rebuild

Posted:

Thu Jan 18, 2018 7:55 pmby rgh0

mbell wrote:I normally connect a garden weed killer spray bottle with oil in it to the oil pressure take off and prime the system that way. My engine never wants to build pressure on the starter until its running so I tend to prime it when I've done things like valve clearance and had the engine out for a while.

I do the same but just use the hand pump bottle that I use to fill gearboxs and diffs. I pump about a litre through the oil passages and back into the pump after filling the filter before assemble. I find I get pressure quickly when I tunr it on the starter

cheers

Rohan

Re: My first engine rebuild

Posted:

Thu Jan 18, 2018 10:52 pmby 2cams70

The critical thing is to wet the oil pump rotors first with engine oil before bolting it on. Just pour some engine oil into the pump ports and rotate the pump by hand several times to ensure a good coverage of oil internally. Even if you pre-fill the filter, fill the oil galleries, etc. pumping just won't happen unless you do this. The internal rotor clearances need to be closed up by a thin coating of oil otherwise air will leak and the pump can't pull a vacuum to draw oil out of the sump.

Also a paper gasket is not really suitable for use under the timing chain pivot and adjustment bolt heads. It's better to use a soft aluminium washer. QED sell them.

Re: My first engine rebuild

Posted:

Fri Jan 19, 2018 2:34 amby seniorchristo

Steve

Have you calculated your compression ratio with the Omega pistons? QED says 12.5 to 1 is "available" with these pistons. This seems excessive for street purposes.

Chris

Re: My first engine rebuild

Posted:

Fri Jan 19, 2018 3:19 amby 2cams70

QED offer race and road type Omega pistons. From the pictures it looks like the road type have been used so no problems. The forging itself is pretty much the same between the two types excluding the valve cutouts and piston dome but the ring packs are different. Road type has single piece oil control ring, race type is three piece. I think the compression rings are a bit wider on the road type too.

Re: My first engine rebuild

Posted:

Fri Jan 19, 2018 7:44 amby Concrete-crusher

The pistons are standard compression , the oil control ring is the single piece with the spring inside.

I did Oil the rotars but will try pumping oil as suggested , also I'm only turning by hand at this stage , so I will wait until it's on the starter motor.

I guess I'm stuck with the paper gasket for now on the pivot bolt , otherwise I need to scrap the rocker gaskets.

Next job is to attach the clutch cover and do a trial fitting to the gearbox , which I bought on eBay as a reconditioned unit.

My clutch cover does not have the thrust pad , so I have the Burton adaptor which brings the bearing forward.

I just got my credit card bill today , ouch I can't quite believe how all this has added up.

Steve

Re: My first engine rebuild

Posted:

Fri Jan 19, 2018 10:23 amby 2cams70

Note If you are using the clutch cover without pad you should also use the corresponding round nose release bearing and not the flat face type

Re: My first engine rebuild

Posted:

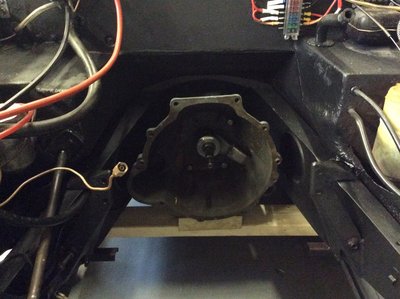

Mon Jan 22, 2018 6:34 pmby Concrete-crusher

Well I got the gearbox back in and clutch setup ready for the engine. I'm not expecting to do this until the weekend.

I also added up the costs , so far a whopping ?2800 , that includes the clutch plate , cover and bearing.

Steve

Re: My first engine rebuild

Posted:

Mon Jan 22, 2018 10:32 pmby MarkDa

Steve

Good progress - well done!

Is Mrs CC on hand to help with engine alignment?!

You should be thinking about tilting the gearbox up to help mating the engine.

Mark

Re: My first engine rebuild

Posted:

Sun Feb 11, 2018 11:48 amby Concrete-crusher

Morning , almost there , I have pumped about 3 litres of oil at 25 psi through the oil pressure sender , but while cranking am not showing any pressure.

I?m cranking for around 20 secs at a time.

My next thought is to remove the oil pump cover and pack it with something.

I have either lm grease , vasalene or graphogen

Any advice ?

Steve

Re: My first engine rebuild

Posted:

Sun Feb 11, 2018 12:13 pmby nmauduit

Concrete-crusher wrote:Morning , almost there , I have pumped about 3 litres of oil at 25 psi through the oil pressure sender , but while cranking am not showing any pressure.

I?m cranking for around 20 secs at a time.

My next thought is to remove the oil pump cover and pack it with something.

I have either lm grease , vasalene or graphogen

Any advice ?

Steve

if you have greased (graphogen etc) the bearings when reassembling, I would try to start the engine once or twice after priming/lubing it as you described, watching the oil pressure light and cutting off if it does not go out after 5-10 sec of running : priming the oil pump may be difficult just by cranking with the starter, which may be slow (depending on battery, starter type etc), and running pre lubed well assembled engine with no load is not going to damage it within 10 seconds. Run it to 2000-2500 rpm, not just idling for a long time at first.

Re: My first engine rebuild

Posted:

Sun Feb 11, 2018 1:10 pmby john.p.clegg

Steve

What I would do is remove the oil pressure sender and rig up a funnel/tube ,push into the sender hole and top up with engine oil...leave for a little while till the level in the funnel has dropped,re-fit the sender and try again..

John