New Engine Build

Put a block on the engine stand to build a new race engine for the Elan. Aiming to have it complete for my next race in early November.

General specs:

1600 cc standard stroke 83.5mm bore 120E block

11.5:1 compression ratio and premium unleaded 98 RON fuel ( Avgas is being banned in historic racing here )

)

Carrillo rods, JE pistons, Datsum L16 crank , 8500 rpm rev limited but good for over 9k+

McCoy Stage 4 converted head 1.625 and 1.4 inch valves with QED race springs( red) and Tony Ingram titanium retainers ( I like to mix and match )

)

McCoy .460 lift 300 degree inlet .450 lift 290 degree exhaust cams

45DCOEs with 36 mm chokes and TTR race headers

Swinging baffle wet sump to my own design with HV / HP pump

Bosch points based distributor, magnecor leads and NGK BP8ES plugs

small diameter crank pulley

shortened jackshaft

lightweight steel flywheel ( I have an alloy one but not sure if I want to try it on this engine)

I was looking to use a new modular water pump front cover but no one has them currently so may need to rebuild and fit one of the spares I have.

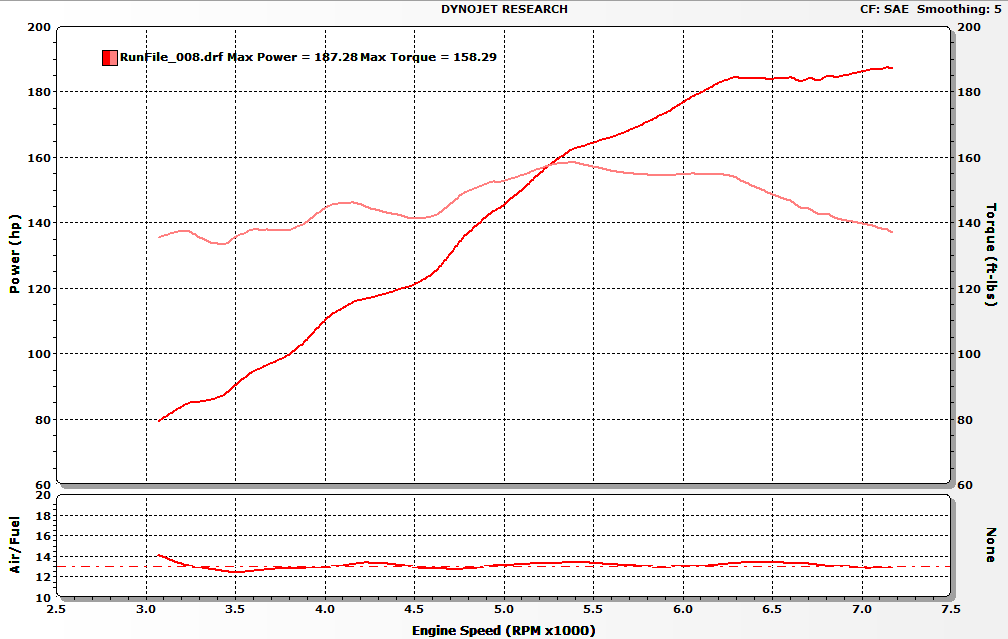

I expect around 180hp at flywheel at around 7500 to 8500 rpm with a nice fat torque curve

I will post some more photos as i go.

cheers

Rohan

General specs:

1600 cc standard stroke 83.5mm bore 120E block

11.5:1 compression ratio and premium unleaded 98 RON fuel ( Avgas is being banned in historic racing here

Carrillo rods, JE pistons, Datsum L16 crank , 8500 rpm rev limited but good for over 9k+

McCoy Stage 4 converted head 1.625 and 1.4 inch valves with QED race springs( red) and Tony Ingram titanium retainers ( I like to mix and match

McCoy .460 lift 300 degree inlet .450 lift 290 degree exhaust cams

45DCOEs with 36 mm chokes and TTR race headers

Swinging baffle wet sump to my own design with HV / HP pump

Bosch points based distributor, magnecor leads and NGK BP8ES plugs

small diameter crank pulley

shortened jackshaft

lightweight steel flywheel ( I have an alloy one but not sure if I want to try it on this engine)

I was looking to use a new modular water pump front cover but no one has them currently so may need to rebuild and fit one of the spares I have.

I expect around 180hp at flywheel at around 7500 to 8500 rpm with a nice fat torque curve

I will post some more photos as i go.

cheers

Rohan