New Engine Build

Finally found time to put the Elan with the new engine on the Dyno. It had run OK at the last race meeting on Avgas but was clearly not quite right and i want to tune it now to run on pump fuel. This engine was a bit of an experiment as I was dropping the compression ratio from 12.5:1 to around 11:1 to run on 98 Octane premium unleaded pump fuel rather than Avgas ( In Australia quoted fuel octane is RON+MON / 2 like in Europe ).

I went to a longer duration and higher lift inlet cam of 0.46 lift and 300 degrees seat to seat to try to compensate while leaving the 0.44 lift 285 degree exhaust cam.

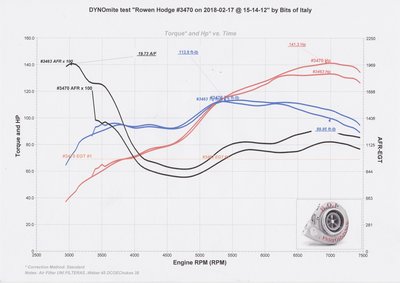

Spent a day on the dyno and did many runs, trying many things. I had used 36mm chokes previously but ended up trying 38mm chokes which gave more top end with no loss of mid-range torque. Also found my fuel pump was not keeping up at the top end and losing pressure so did the dyno work with a temporary set up - new pump and fuel line to go in next weekend !

Dyno curves for the best 36mm choke result and the final 38 mm choke are attached. 141 HP at the back wheels is not bad for a 1600 twink in an Elan with a 3.77 diff in top The curve drops off at 7400 rpm but this is the dyno safety cutoff setting, it would have pulled with similar power well over 8000 rpm

The curve drops off at 7400 rpm but this is the dyno safety cutoff setting, it would have pulled with similar power well over 8000 rpm

Also have one noisy exhaust tappet that I need to have a look at, must have got the clearance a little big

cheers

Rohan

I went to a longer duration and higher lift inlet cam of 0.46 lift and 300 degrees seat to seat to try to compensate while leaving the 0.44 lift 285 degree exhaust cam.

Spent a day on the dyno and did many runs, trying many things. I had used 36mm chokes previously but ended up trying 38mm chokes which gave more top end with no loss of mid-range torque. Also found my fuel pump was not keeping up at the top end and losing pressure so did the dyno work with a temporary set up - new pump and fuel line to go in next weekend !

Dyno curves for the best 36mm choke result and the final 38 mm choke are attached. 141 HP at the back wheels is not bad for a 1600 twink in an Elan with a 3.77 diff in top

Also have one noisy exhaust tappet that I need to have a look at, must have got the clearance a little big

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8416

- Joined: 22 Sep 2003

rgh0 wrote:Finally found time to put the Elan with the new engine on the Dyno. It had run OK at the last race meeting on Avgas but was clearly not quite right and i want to tune it now to run on pump fuel. This engine was a bit of an experiment as I was dropping the compression ratio from 12.5:1 to around 11:1 to run on 98 Octane premium unleaded pump fuel rather than Avgas ( In Australia quoted fuel octane is RON+MON / 2 like in Europe ).

I went to a longer duration and higher lift inlet cam of 0.46 lift and 300 degrees seat to seat to try to compensate while leaving the 0.44 lift 285 degree exhaust cam.

Spent a day on the dyno and did many runs, trying many things. I had used 36mm chokes previously but ended up trying 38mm chokes which gave more top end with no loss of mid-range torque. Also found my fuel pump was not keeping up at the top end and losing pressure so did the dyno work with a temporary set up - new pump and fuel line to go in next weekend !

Dyno curves for the best 36mm choke result and the final 38 mm choke are attached. 141 HP at the back wheels is not bad for a 1600 twink in an Elan with a 3.77 diff in topThe curve drops off at 7400 rpm but this is the dyno safety cutoff setting, it would have pulled with similar power well over 8000 rpm

Also have one noisy exhaust tappet that I need to have a look at, must have got the clearance a little big

cheers

Rohan

What pump arrangement (pressure/flow rate) do you envisage having to use? What is the size of your fuel line and do you use a pressure regulator after the pump(s)?

Cheers

Graeme

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

-

661 - Coveted Fifth Gear

- Posts: 1198

- Joined: 29 Mar 2012

I will be using a Carter universal electric pump that puts up 5 to 6 PSI in the boot with a 8 mm ( 5/16 inch) braided line to the engine and Petrol King regulator set at 3 PSI in the engine bay. The test set up used this pump and regulator and held a rock solid 3 PSI over the full range.

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8416

- Joined: 22 Sep 2003

rgh0 wrote:I will be using a Carter universal electric pump that puts up 5 to 6 PSI in the boot with a 8 mm ( 5/16 inch) braided line to the engine and Petrol King regulator set at 3 PSI in the engine bay. The test set up used this pump and regulator and held a rock solid 3 PSI over the full range.

cheers

Rohan

Is this 'test set up' different to the one you used on the dyno. Sorry, I couldn't work that bit out.

Graeme

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

-

661 - Coveted Fifth Gear

- Posts: 1198

- Joined: 29 Mar 2012

Rohan,

I have a small equation that idicates airflow due to valve size. 1.625 comes out at 178.4bhp, however everything else must match. Its fairly accurate, not 100% but close.

All things being equal it puts your dyno figures at 22% losses. If you assume your hitting the figure above.

In laymans terms i think that makes yours bang on,

Nice one.

I have a small equation that idicates airflow due to valve size. 1.625 comes out at 178.4bhp, however everything else must match. Its fairly accurate, not 100% but close.

All things being equal it puts your dyno figures at 22% losses. If you assume your hitting the figure above.

In laymans terms i think that makes yours bang on,

Nice one.

Kick the tyres and light them fires...!!!!!!!

- pauljones

- Fourth Gear

- Posts: 828

- Joined: 09 Feb 2008

nmauduit wrote:Thank you for posting the curve Rohan, and details.

I was looking at the lambda output, which seems to be on the rich side of 12.5 up to about 7000 rpm : is that a choice ?

Yes it was a selection based on a number of runs. The engine liked to be on the rich side and this gave the optimum power and torque curves

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8416

- Joined: 22 Sep 2003

661 wrote:rgh0 wrote:I will be using a Carter universal electric pump that puts up 5 to 6 PSI in the boot with a 8 mm ( 5/16 inch) braided line to the engine and Petrol King regulator set at 3 PSI in the engine bay. The test set up used this pump and regulator and held a rock solid 3 PSI over the full range.

cheers

Rohan

Is this 'test set up' different to the one you used on the dyno. Sorry, I couldn't work that bit out.

On the dyno when we discovered the fuel pressure loss at high loads we hooked up the carter pump and regulator and hose as a test setup. The dyno guy has a trolley with this setup that he could just wheel next to the car to run it.

I will duplicate that test setup, permanently in the car

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8416

- Joined: 22 Sep 2003

pauljones wrote:Rohan,

I have a small equation that idicates airflow due to valve size. 1.625 comes out at 178.4bhp, however everything else must match. Its fairly accurate, not 100% but close.

All things being equal it puts your dyno figures at 22% losses. If you assume your hitting the figure above.

In laymans terms i think that makes yours bang on,

Nice one.

I have a detailed engine simulation program that allows you to model most parameters in an engine design. For this build it says around 175 to 180 hp at the flywheel so 141 at the back wheels is about right. I typically find about 5 to 6 hp losses per 1000 rpm with 25 psi in the tyres and the 3.77 diff I run, so at 7000 rpm 35 to 42 hp of losses gives 176 to 183 hp. Pretty happy with the experiment and shows what is possible on pump fuel and a relatively modest compression ratio if you stick with relatively short duration high lift cams.

Thus a healthy big valve twin cam will get around 95 hp at the wheels with around 30 hp of losses at 6000 rpm.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8416

- Joined: 22 Sep 2003

If i remember corectly im sure its valve dia squared x pi, ?4 =valve area. X by amount of intake valves then ? 30.

So 1.625x25.4=41.275mm

41.275 x 41.275 x pi = 5352.09 ?4, x 4 (no of intake valves) ? 30 = 178.40bhp

Must have all supporting mods.

So 1.625x25.4=41.275mm

41.275 x 41.275 x pi = 5352.09 ?4, x 4 (no of intake valves) ? 30 = 178.40bhp

Must have all supporting mods.

Kick the tyres and light them fires...!!!!!!!

- pauljones

- Fourth Gear

- Posts: 828

- Joined: 09 Feb 2008

pauljones wrote:If i remember corectly im sure its valve dia squared x pi, ?4 =valve area. X by amount of intake valves then ? 30.

So 1.625x25.4=41.275mm

41.275 x 41.275 x pi = 5352.09 ?4, x 4 (no of intake valves) ? 30 = 178.40bhp

Must have all supporting mods.

This formula works on the principle that the maximum flow though an inlet valve is determined by the valve port area when its opened at typically maximum achievable lifts and that you have sonic flow through the valve port which sets the maximum flow rate achievable. Maximum achievable power is then directly related to maximum port flow rates based on valve port area

The "must have all supporting mods" is the key phrase as the inlet valve needs to be the limit and not the many many other things which can limit e.g. carbs or ports or inlet manifold ,exhaust valves ,ports or manifold or mufflers or cam duration and lift or engine revs or combustion chamber shape or ignition timing or compression ratio and fuel etc .

The trade offs are infinite in this set of combinations and you may choose 10 more or maybe 20 less HP in a 1600 twink with 1.625 inlets to give say 160 to 190 hp depending of the engine characteristics wanted and the type of car its in.

e.g. Around 160 hp for 285 degree .44 lift cams for a road going Elan, Around 190 Hp for 320 degree .49 lift inlets in a light open wheeler with a big 4:1 exhaust. To get to the mythical 200 hp in a 1600 twink you need everything just right and focused on top end power and probably also need to go for 1.7 inlets and "all required supporting modifications.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8416

- Joined: 22 Sep 2003

rgh0 wrote:661 wrote:rgh0 wrote:I will be using a Carter universal electric pump that puts up 5 to 6 PSI in the boot with a 8 mm ( 5/16 inch) braided line to the engine and Petrol King regulator set at 3 PSI in the engine bay. The test set up used this pump and regulator and held a rock solid 3 PSI over the full range.

cheers

Rohan

Is this 'test set up' different to the one you used on the dyno. Sorry, I couldn't work that bit out.

On the dyno when we discovered the fuel pressure loss at high loads we hooked up the carter pump and regulator and hose as a test setup. The dyno guy has a trolley with this setup that he could just wheel next to the car to run it.

I will duplicate that test setup, permanently in the car

cheers

Rohan

Thanks, and finally....

Will you run two pumps in parallel from the boot which are switchable on/off from the dash?

Last edited by 661 on Sun Feb 18, 2018 9:12 am, edited 1 time in total.

Graeme

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

-

661 - Coveted Fifth Gear

- Posts: 1198

- Joined: 29 Mar 2012

Just one pump. The chances of a pump failure during a race is small. Never had one fail in the last 40 years of competition or in a road going Lotus either for that matter. Change the filter regularly and check the wiring, the pumps themselves are very reliable.

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8416

- Joined: 22 Sep 2003

Total Online:

Users browsing this forum: No registered users and 25 guests