Slow Return to Idle / Bypass Valves

14 posts

• Page 1 of 1

Running into a bit of a confusing problem on my Stromberg equipped federal Elan+2.

I've noticed that if I am just puttering around town, when I come to a stop, the engine returns to idle reasonably quick. Not straight away but very quickly. However, the harder and longer that I drive at speed the longer it returns to idle.

As an example, if I run on the highway for 15 min and come to a stop the idle will sit at 1,600 and slow drift back down to 900 - 1,000 over the course of a minute or two. If I am doing a short hard run it might sit at 1,300 and then come back to idle over a much shorter period of time.

I'm honestly a little confused as to what could be...

It doesn't seem like a vacuum leak since the idle doesn't stay persistently high. The idle eventually returns to normal and it is easy to tune the idle up and down.

My other thought is that it might be a sticky throttle cable but I don't know why that would vary with the length of a run on the highway. It seems like it should stick or it shouldn't?

Could it be faulty or old temperature compensators?

I did some searching around but was coming up short and thought I'd throw it to the wisdom of the crowds before I started blindly poking around.

I've noticed that if I am just puttering around town, when I come to a stop, the engine returns to idle reasonably quick. Not straight away but very quickly. However, the harder and longer that I drive at speed the longer it returns to idle.

As an example, if I run on the highway for 15 min and come to a stop the idle will sit at 1,600 and slow drift back down to 900 - 1,000 over the course of a minute or two. If I am doing a short hard run it might sit at 1,300 and then come back to idle over a much shorter period of time.

I'm honestly a little confused as to what could be...

It doesn't seem like a vacuum leak since the idle doesn't stay persistently high. The idle eventually returns to normal and it is easy to tune the idle up and down.

My other thought is that it might be a sticky throttle cable but I don't know why that would vary with the length of a run on the highway. It seems like it should stick or it shouldn't?

Could it be faulty or old temperature compensators?

I did some searching around but was coming up short and thought I'd throw it to the wisdom of the crowds before I started blindly poking around.

Last edited by 1969Plus2 on Mon Jun 17, 2019 4:04 pm, edited 1 time in total.

- 1969Plus2

- First Gear

- Posts: 41

- Joined: 04 Jun 2019

The throttle bypass valve may be sticking open longer than it should. On closed throttle over-run, or any time the throttle is closed suddenly, the bypass valve opens a port that allows a flow of air to bypass the closed throttle. That has the same affect as keeping the throttle open a bit. The bypass slowly closes, but it should only take a few seconds, not minutes.

It's an emissions thing that minimizes the spike in oxides of nitrogen that can occur during the high manifold vacuum conditions that can exist during closed throttle over-run, and any sudden closure of the throttle.

It sounds like your bypass valves may be working to excess. A good cleaning might help. Or...

Remove the bypass valves. Holes through the gasket allow bypass air to cross the joint line into the bypass valve, where the flow is turned on and off. Hand cut a replacement gasket that is solid... no holes, except for the necessary screw holes. Then re-assemble. The blank gasket will totally disable the bypass valves. "IF" the bypass valves are the problem, disabling them should both solve the problem and give a more crisp throttle response. If it has no impact, then there is probably a different air leak at work somewhere.

Regards,

Tim Engel

It's an emissions thing that minimizes the spike in oxides of nitrogen that can occur during the high manifold vacuum conditions that can exist during closed throttle over-run, and any sudden closure of the throttle.

It sounds like your bypass valves may be working to excess. A good cleaning might help. Or...

Remove the bypass valves. Holes through the gasket allow bypass air to cross the joint line into the bypass valve, where the flow is turned on and off. Hand cut a replacement gasket that is solid... no holes, except for the necessary screw holes. Then re-assemble. The blank gasket will totally disable the bypass valves. "IF" the bypass valves are the problem, disabling them should both solve the problem and give a more crisp throttle response. If it has no impact, then there is probably a different air leak at work somewhere.

Regards,

Tim Engel

Last edited by Esprit2 on Wed Jun 05, 2019 1:39 am, edited 1 time in total.

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Tim, good idea. I went ahead and rebuilt both bypass valves and the problem seems to have more or less resolved itself. That said, I am not totally sure that the gaskets / valves were bad. Rather, I think that the throttle bypass valve on 3 / 4 was adjusted way out of tune, with a huge amount of allowable movement. When I rebuilt them I set the adjustment screw such that the hex was just seated into the body of the outermost casting and then dropped it further by one turn.

I found a great resource here: https://static1.squarespace.com/static/ ... art+II.pdf

All that said, I am still a bit confused about the exact way the bypass valves work. Where exactly do these things sense the pressure differential? Does the valve sit directly across the butterfly, which would allow the pressure differential before and after to move the throttle bypass valve?

I found a great resource here: https://static1.squarespace.com/static/ ... art+II.pdf

All that said, I am still a bit confused about the exact way the bypass valves work. Where exactly do these things sense the pressure differential? Does the valve sit directly across the butterfly, which would allow the pressure differential before and after to move the throttle bypass valve?

- 1969Plus2

- First Gear

- Posts: 41

- Joined: 04 Jun 2019

Whenever the throttle is suddenly closed while the engine is at speed (either simply blipping the throttle, or closed throttle over-run/ engine braking), a very strong intake manifold vacuum is generated. And the oxides of nitrogen (NOx) emissions spike during those high vacuum conditions. The Bypass Valve is an emissions control devices that is meant to minimize those NOx emissions.

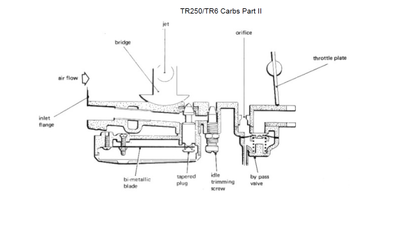

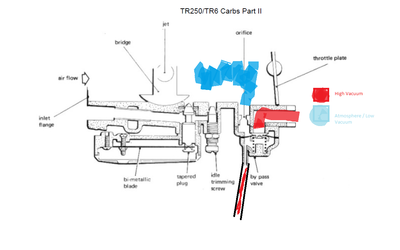

Go to page 4/9 of the Triumph article that you mentioned. The illustration at the top of the page clearly shows the bypas valve in cross-section.

There is an air channel that breaks into the carb throat just before the butterfly. There's an orifice (jet) in the opening to limit how much air can bypass the butterfly when the Bypass Valve is open. The Bypass Valve itself is just a diaphragm valve that's normally closed, but is opened by vacuum. An external rubber hose delivers vacuum from a spigot on the intake manifold to the spigot on the Bypass Valve.

During periods of closed throttle over-run, the strong manifold vacuum works against the Bypass Valves diaphragm, opening the valve and allowing metered air to flow around the butterfly. The engine doesn't care how the air got through the carb... air/fuel mixture is air/fuel mixture regardless of how it gets into the engine. So while vacuum holds the Bypass Valve open, the engine continues to run at a faster than idle speed, reducing the closed throttle vacuum and oxides of nitrogen.

In most applications, the vacuum hose goes from the intake manifold to a Delay Valve, and then on to the Bypass Valve. The Delay Valve allows the vacuum to slowly bleed off, gradually closing the Bypass Valve over a period of seconds. The goal isn't to bypass the butterfly, rather to 'soften' the effect of it suddenly slamming shut.

Some other types of carbs addressed the same problem by putting a small 'dashpot' between the throttle linkage and it's stop. Think of the dashpot as a shock absorber/ damper that gets squeezed when the throttle is closed. It's a diaphragm capsule vented to the atmosphere through a small orifice. It's spring loaded to expand, filling with air whenever the throttle linkage is lifted off of it (ie, when it's no longer pinched by the throttle linkage). When the throttle is closed, the expanded dashpot catches the linkage before it reaches the throttle stop, then slowly lowers it to the stop as the air inside the dashpot bleeds out through the small orifice.

The Bypass Valve and Dashpot are effectively doing the same thing. On closed-throttle over-run, they both prevent the throttle from abruptly cutting off the air flow through the carb. They provide a 'soft' closure, either by mechanically dampening the butterfly's linkage closure, or by providing a temporary alternate air flow path around the butterfly.

All that is for the same of emissions, and the engine will run better/ fell more responsive to throttle inputs if the dashpot is removed or the Bypass Valve is defeated.

Regards,

Tim Engel

Go to page 4/9 of the Triumph article that you mentioned. The illustration at the top of the page clearly shows the bypas valve in cross-section.

There is an air channel that breaks into the carb throat just before the butterfly. There's an orifice (jet) in the opening to limit how much air can bypass the butterfly when the Bypass Valve is open. The Bypass Valve itself is just a diaphragm valve that's normally closed, but is opened by vacuum. An external rubber hose delivers vacuum from a spigot on the intake manifold to the spigot on the Bypass Valve.

During periods of closed throttle over-run, the strong manifold vacuum works against the Bypass Valves diaphragm, opening the valve and allowing metered air to flow around the butterfly. The engine doesn't care how the air got through the carb... air/fuel mixture is air/fuel mixture regardless of how it gets into the engine. So while vacuum holds the Bypass Valve open, the engine continues to run at a faster than idle speed, reducing the closed throttle vacuum and oxides of nitrogen.

In most applications, the vacuum hose goes from the intake manifold to a Delay Valve, and then on to the Bypass Valve. The Delay Valve allows the vacuum to slowly bleed off, gradually closing the Bypass Valve over a period of seconds. The goal isn't to bypass the butterfly, rather to 'soften' the effect of it suddenly slamming shut.

Some other types of carbs addressed the same problem by putting a small 'dashpot' between the throttle linkage and it's stop. Think of the dashpot as a shock absorber/ damper that gets squeezed when the throttle is closed. It's a diaphragm capsule vented to the atmosphere through a small orifice. It's spring loaded to expand, filling with air whenever the throttle linkage is lifted off of it (ie, when it's no longer pinched by the throttle linkage). When the throttle is closed, the expanded dashpot catches the linkage before it reaches the throttle stop, then slowly lowers it to the stop as the air inside the dashpot bleeds out through the small orifice.

The Bypass Valve and Dashpot are effectively doing the same thing. On closed-throttle over-run, they both prevent the throttle from abruptly cutting off the air flow through the carb. They provide a 'soft' closure, either by mechanically dampening the butterfly's linkage closure, or by providing a temporary alternate air flow path around the butterfly.

All that is for the same of emissions, and the engine will run better/ fell more responsive to throttle inputs if the dashpot is removed or the Bypass Valve is defeated.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Drawing referenced for others:

This all makes sense to me and I think you hit on the one piece that I am missing: how do you get high manifold vacuum to open the by pass valve?

Presumably, you would draw vacuum from the capped off pipe at the top of my by pass valve, thought mine was never hooked up. However, wouldn't the vacuum from the manifold counteract that force? I've tried to mock up in a drawing what my words probably fail to convey.

This all makes sense to me and I think you hit on the one piece that I am missing: how do you get high manifold vacuum to open the by pass valve?

Presumably, you would draw vacuum from the capped off pipe at the top of my by pass valve, thought mine was never hooked up. However, wouldn't the vacuum from the manifold counteract that force? I've tried to mock up in a drawing what my words probably fail to convey.

- 1969Plus2

- First Gear

- Posts: 41

- Joined: 04 Jun 2019

Slightly off-topic, but the Temperature Compensator is similar but different. The basic carb has a straight throat, interupted by an Air Valve (piston) and then by a butterfly. Then they added some external bypass circuits to moderate normal function. The Bypass Valve was discussed above, and it bypasses the butterfly. The Temperature Compensator (TC) bypasses the Air Valve/ piston.

The TC has a bi-metalic strip that is temperature sensitive, and opens/ closes an air passage that shunts around the Air Valve/ piston. Doing so alters the pressure drop/ vacuum that occurs in the throat across the piston. And playing with that vacuum alters how high the piston is lifted, which plays with the air-fuel ratio (lower is leaner, higher is richer). The Temperature Compensator is supposed to provide a temporarily richer mixture whenever the ambient air (engine bay air) is cooler. As the air temp increases, the air-fuel ratio trends back toward the carb's emissions-lean setting. Again, it's an emissions thing. The carb is adjusted so emissions-lean that it can cause poor running under certain conditions. In this case, cool running.

The TC can help with normal cold starts, but there's a choke/ enrichment device that covers that. So the TC's main function is to preserve good running/ driveability during cooler seasons... Winter. Since most of the vintage cars that used Z-S carbs are now collector cars that aren't used during frigid Winter weather, the TC isn't as important as it originally was. And if the engine no longer has to pass an annual emissions test where you live, then the engine will run better if the air-fuel mixture is re-adjusted richer for 'best running', and the Temperature Compensator is defeated.

Both the TC and the Bypass Valve are crutches that help the carbs cope with emissions issues. Both of them sorta work, but they also have downsides. The engine will run better if the emissions issues and the compensating crutches are eliminated.

Regards,

Tim Engel

The TC has a bi-metalic strip that is temperature sensitive, and opens/ closes an air passage that shunts around the Air Valve/ piston. Doing so alters the pressure drop/ vacuum that occurs in the throat across the piston. And playing with that vacuum alters how high the piston is lifted, which plays with the air-fuel ratio (lower is leaner, higher is richer). The Temperature Compensator is supposed to provide a temporarily richer mixture whenever the ambient air (engine bay air) is cooler. As the air temp increases, the air-fuel ratio trends back toward the carb's emissions-lean setting. Again, it's an emissions thing. The carb is adjusted so emissions-lean that it can cause poor running under certain conditions. In this case, cool running.

The TC can help with normal cold starts, but there's a choke/ enrichment device that covers that. So the TC's main function is to preserve good running/ driveability during cooler seasons... Winter. Since most of the vintage cars that used Z-S carbs are now collector cars that aren't used during frigid Winter weather, the TC isn't as important as it originally was. And if the engine no longer has to pass an annual emissions test where you live, then the engine will run better if the air-fuel mixture is re-adjusted richer for 'best running', and the Temperature Compensator is defeated.

Both the TC and the Bypass Valve are crutches that help the carbs cope with emissions issues. Both of them sorta work, but they also have downsides. The engine will run better if the emissions issues and the compensating crutches are eliminated.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Tim, re the temp compensators, do you have any information on how the Elan ones should be set. Specifically the temperature at which they start to open and the fully open temperature. I ask because I've not been able to find anything at all for Elans other than don't touch them / replace them. There is information for other cars that use similar set ups - the Buckeye Triumph source for example suggesting it should be somewhere in the 40/50C range and other stuff for Volvos saying it should be much lower (in the mid 20'sC) so it would seem there's not a universal setting for them.

I've seen many reports that say screw them up tight and then ignore them but I think that comes from not thinking through why they're there. There may be an emissions element to their function in the federal setup but I don't think that was much of a consideration over here in the late 60's. They seem to have more of a role to play in hot starting When mine are adjusted / jammed shut the car can be very difficult to start once its heat soaked for five or ten minutes. When I measured carb temperatures under those circumstances it was in the mid 50'sC. By trial and error I've found that by setting the TCs to start opening at 40C and be fully open by the mid 50'sC hot starting is transformed. During normal running the carbs are below 40C so the TCs are shut and playing no role in the carbs functioning. However those are my subjective settings based on what works for my car. What Lotus / Z-S set them to originally I have no idea.

I've seen many reports that say screw them up tight and then ignore them but I think that comes from not thinking through why they're there. There may be an emissions element to their function in the federal setup but I don't think that was much of a consideration over here in the late 60's. They seem to have more of a role to play in hot starting When mine are adjusted / jammed shut the car can be very difficult to start once its heat soaked for five or ten minutes. When I measured carb temperatures under those circumstances it was in the mid 50'sC. By trial and error I've found that by setting the TCs to start opening at 40C and be fully open by the mid 50'sC hot starting is transformed. During normal running the carbs are below 40C so the TCs are shut and playing no role in the carbs functioning. However those are my subjective settings based on what works for my car. What Lotus / Z-S set them to originally I have no idea.

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

Stuart,

Sorry, but I don't have any Elan-specific settings for the Temperature Compensator. I'm certain that I had a comprehensive listing a couple of dead computers ago, but nothing that I can find now.

And you're correct, they were specifically set for each engine application, and there is no universal setting that works for all. We should be so lucky.

Regards,

Tim Engel

Sorry, but I don't have any Elan-specific settings for the Temperature Compensator. I'm certain that I had a comprehensive listing a couple of dead computers ago, but nothing that I can find now.

And you're correct, they were specifically set for each engine application, and there is no universal setting that works for all. We should be so lucky.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

The bypass valves should be adjusted to be normally closed, then opened by vacuum. But 50 years down the road, there's no guarantee that they are still properly adjusted, or that the diaphragms haven't rotted out. If you can confirm that they're good, then yes, disconnecting and plugging both ends of the vacuum line (at the manifold and at the bypass valves) should defeat them. Replacing the gasket with a hand-cut solid gasket is just a belt & suspenders approach.

Regards,

Tim Engel

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Tim, when I bought the car the car the bypass valves had been disconnected from a source of vacuum. Which, now that I think about it makes my original problem all the more strange. My hunch is that one was rotted out a bit and the spring was very loose, which may have allowed it to flutter in place.

Since I went ahead and rebuilt both bypass valves, it looks like I have more or less defeated the system unintentionally!

Since I went ahead and rebuilt both bypass valves, it looks like I have more or less defeated the system unintentionally!

- 1969Plus2

- First Gear

- Posts: 41

- Joined: 04 Jun 2019

69S4 wrote:temp compensators...seem to have more of a role to play in hot starting When mine are adjusted / jammed shut the car can be very difficult to start once its heat soaked for five or ten minutes. When I measured carb temperatures under those circumstances it was in the mid 50'sC. By trial and error I've found that by setting the TCs to start opening at 40C and be fully open by the mid 50'sC hot starting is transformed. During normal running the carbs are below 40C so the TCs are shut and playing no role in the carbs functioning. However those are my subjective settings based on what works for my car...

Thanks for sharing this observation, Stuart, though I'm not sure I fully understand. Why would a leaner condition improve hot starting? When I rebuilt mine I set them to start reopening about 40C, too, so should be in the same boat - but didn't anticipate impacting this particular issue (which did get reduced after carb rebuild, but I suspected was due to replacement of rock-hard o-rings with pliable o-rings in the mount).

Henry

69 Elan S4

65 Seven S2

69 Elan S4

65 Seven S2

- SENC

- Coveted Fifth Gear

- Posts: 1018

- Joined: 30 Dec 2015

Hot starting problems with Strombergs seems to be an issue of an over rich mixture - a bit like putting the choke on except internally generated. You would think that if you've got the needle adjusted correctly and there's no other faults that the mixture would be correct throughout the range - after all that's what the various needle profiles are for, to keep the mixture under tight control, but trying to restart the engine when the carb has been heat soaked seems to be a special condition outside the capacity of the needle to cope with.

Exactly why this should be so is hard to pin down but I suspect it's something to do with decreased hot air density together with hot fuel viscosity / vaporisation characteristics - basically more fuel than should be is fed into local hot air that can't carry it. Others with a background in this kind of stuff may know more but that's what my simplistic analysis suggests.

The way the TCs work is that by bleeding air into the low pressure area behind the needle the pressure differential is reduced so the needle doesn't rise as far. That reduces the amount of fuel fed into the air stream - a weaker mixture. As soon as the engine starts cool air + 'latent cooling' from the fuel flow reduces the carb body temperature to the point where the TCs close and order is restored.

There is some suggestion in the 'literature' -ie other internet posts - that the TCs still (should) bleed some air during normal running but if they're supposed to the reason goes beyond my understanding of what's going on. Mine are set to start opening at just over 40C and that's higher than the normal running temperature of the carb bodies as measured by my IR thermometer. They only get above that when a hot engine is stopped. Maybe if you're driving in ambient temps around 40C then some extra compensation is needed but conditions like that are rare (to say the least) in the UK.

When my car was at the height of its hot starting tantrums a while back I could often smell petrol after it had been left for 15-20 mins suggesting there was more of it around than there should be. With the original Lucas starter the engine would often fire once, throw the bendix out and then stop. Repeating that would get me nowhere until the engine cooled - 1-2 hrs, something not that convenient if all I'd done is stop for fuel. Push starting it would always work but that's not so easy if you're on your own / road is uphill etc. Since I've worked on the TCs its never failed to hot start - even though I still have a degree of apprehension when I turn the key when its really hot.

Exactly why this should be so is hard to pin down but I suspect it's something to do with decreased hot air density together with hot fuel viscosity / vaporisation characteristics - basically more fuel than should be is fed into local hot air that can't carry it. Others with a background in this kind of stuff may know more but that's what my simplistic analysis suggests.

The way the TCs work is that by bleeding air into the low pressure area behind the needle the pressure differential is reduced so the needle doesn't rise as far. That reduces the amount of fuel fed into the air stream - a weaker mixture. As soon as the engine starts cool air + 'latent cooling' from the fuel flow reduces the carb body temperature to the point where the TCs close and order is restored.

There is some suggestion in the 'literature' -ie other internet posts - that the TCs still (should) bleed some air during normal running but if they're supposed to the reason goes beyond my understanding of what's going on. Mine are set to start opening at just over 40C and that's higher than the normal running temperature of the carb bodies as measured by my IR thermometer. They only get above that when a hot engine is stopped. Maybe if you're driving in ambient temps around 40C then some extra compensation is needed but conditions like that are rare (to say the least) in the UK.

When my car was at the height of its hot starting tantrums a while back I could often smell petrol after it had been left for 15-20 mins suggesting there was more of it around than there should be. With the original Lucas starter the engine would often fire once, throw the bendix out and then stop. Repeating that would get me nowhere until the engine cooled - 1-2 hrs, something not that convenient if all I'd done is stop for fuel. Push starting it would always work but that's not so easy if you're on your own / road is uphill etc. Since I've worked on the TCs its never failed to hot start - even though I still have a degree of apprehension when I turn the key when its really hot.

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

14 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 27 guests