Timing chain and reshimming tappets

14 posts

• Page 1 of 1

Sorry to disagree but I don't think that it is vital to keep tension on the chain. Provided that the crank sprocket is set to TDC for No 1 cylinder when putting it all back together and the camshaft sprockets are also correctly set then no problems. Remember that the only important thing is the correct orientation of crank, inlet and exhaust sprockets relative to each other. When refitting the chain then the run between crank and exhaust sprockets needs to be tight - all other chain adjustments can be made using the tensioner mechanism but remember that operating that mechanism will rotate the inlet can sprocket as the chain moves.

Worth putting a screwdriver/pencil/whatever through the chain loop and across the top of the timing chest - stops the chain falling into the bottom.

Miles Wilkins' book covers valve shimming/timing etc in some detail.

Martin B

Worth putting a screwdriver/pencil/whatever through the chain loop and across the top of the timing chest - stops the chain falling into the bottom.

Miles Wilkins' book covers valve shimming/timing etc in some detail.

Martin B

Time flies like an arrow; fruit flies like a banana.

72 Europa Special, 72 Sprint, 72 Plus 2

72 Europa Special, 72 Sprint, 72 Plus 2

- martinbrowning

- Third Gear

- Posts: 260

- Joined: 07 Jun 2007

William2 wrote:I assume that I don't have to slacken the chain tensioner off to remove the cam shafts or sprockets??

I do slacken the chain tensioner before removing the sprockets. My previous post did not go through somehow, but in a nutshell I suppose the intent is to minimize the intervention length with the engine in the car : as I find it difficult to keep the timing after the camshafts have been removed, I just keep the chain attached so that it does not fall but do not lose time trying preserve the exact angular position of the cranck and cams, and I always set the timing again after the camshafts are back (that includes ignition timing).

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2000

- Joined: 02 Sep 2013

If all I'm doing is shimming a Twin Cam's valve clearances, then I've found the simple way to be...

1) Remove the cam bearing caps from one cam, freeing it.

2) Grasp the sprocket and apply firm upward pressure, lifting the front of the cam out of the front cam bearings as far as timing chain slack will allow.

3) Gradually unscrew the tensioner, allowing you to lift the sprocket & cam's forward end until the front cam journal is above the bearing in the head, then stop. Go no further than necessary.

4) Lift the back end of the cam higher than level, as necessary to allow that end to be swung to one side, over the head. Not far. Just a slight angle, far enough to find a resting spot for the cam. Lay the cam down on the head, while still maintaining upward pressure on the sprocket.

Ample use of foam or folded shop towel pads between the cam and head is recommended, although they're not 'required' if care is exercised.

Neither the chain nor it's mesh with the sprocket is rigid. There's enough flex available to allow the camshaft to be gently skewed slightly to one side or the other, as required to lay it at a slight angle across the head. NOT 90 degrees across the head. Just enough of an angle to find a spot, and far enough that the cam doesn't tend to drop back into the head. The sprocket is still in roughly the same location, just higher than normal, and slightly cocked with the tail end of the cam off to one side. There's just enough slack in the chain to allow the sprocket to rise as much as required, without ever introducing enough slack to allow the chain to come off either the cam or crank sprocket.

5) Maintain upward pressure on the sprocket & chain throughout the move. Once the back end of the cam is laid on the head, screw the tensioner back in only enough to pull the sprocket back down against upward hand-pressure, to a now 'crooked' rest position. Release the upward hand-pressure on the sprocket and chain only after the cam is at rest in it's new position.

Do what you need to do with tappets and shims, then...

6) Reverse the process. Grasp the sprocket and apply upward pressure while unscrewing the tensioner far enough to lift the cam to minimally clear of the head.

7) Lift the rear of the cam above level, and swing it back over into alignment with the bearing journals. Lower the back end down into the rear bearing, but maintain upward pressure on the sprocket.

8. Screw the tensioner in, drawing the sprocket and front end of the cam down until the cam rests in the front cam bearing journal. Or as close as it can get if valve springs & tappets are holding the cam up. No extra slack in the chain, but not 'tight'.

9) Install the cam bearing caps and torque tighten. Tightening the caps may draw the cam down against valve spring pressure. Watch timing chain slack as you draw the cam down, and tighten the tensioner periodically to prevent the chain from going slack enough to drop off the crank sprocket.

10) Repeat for the second cam.

11) Properly tension the timing chain, and double-check the cam timing.

It works. I've never 'fully' removed a cam just to shim the valve clearances in a Twin Cam. Properly done, there's never enough slack added to the timing chain loop to allow it to disengage from the crank sprocket, and the timing that was present at the start of the process isn't lost. Still, inspect the cam timing on a paranoid scale, but properly done, the timing shouldn't jump/ be lost. If the cam timing was wrong when you started, it will still be wrong when you finish... so always check the cam timing, and end with it being correct.

If all you do is shim the valves using this method, it doesn't take very long. I've showed the method to a few friends, who now use it as well.

Regards,

Tim Engel

1) Remove the cam bearing caps from one cam, freeing it.

2) Grasp the sprocket and apply firm upward pressure, lifting the front of the cam out of the front cam bearings as far as timing chain slack will allow.

3) Gradually unscrew the tensioner, allowing you to lift the sprocket & cam's forward end until the front cam journal is above the bearing in the head, then stop. Go no further than necessary.

4) Lift the back end of the cam higher than level, as necessary to allow that end to be swung to one side, over the head. Not far. Just a slight angle, far enough to find a resting spot for the cam. Lay the cam down on the head, while still maintaining upward pressure on the sprocket.

Ample use of foam or folded shop towel pads between the cam and head is recommended, although they're not 'required' if care is exercised.

Neither the chain nor it's mesh with the sprocket is rigid. There's enough flex available to allow the camshaft to be gently skewed slightly to one side or the other, as required to lay it at a slight angle across the head. NOT 90 degrees across the head. Just enough of an angle to find a spot, and far enough that the cam doesn't tend to drop back into the head. The sprocket is still in roughly the same location, just higher than normal, and slightly cocked with the tail end of the cam off to one side. There's just enough slack in the chain to allow the sprocket to rise as much as required, without ever introducing enough slack to allow the chain to come off either the cam or crank sprocket.

5) Maintain upward pressure on the sprocket & chain throughout the move. Once the back end of the cam is laid on the head, screw the tensioner back in only enough to pull the sprocket back down against upward hand-pressure, to a now 'crooked' rest position. Release the upward hand-pressure on the sprocket and chain only after the cam is at rest in it's new position.

Do what you need to do with tappets and shims, then...

6) Reverse the process. Grasp the sprocket and apply upward pressure while unscrewing the tensioner far enough to lift the cam to minimally clear of the head.

7) Lift the rear of the cam above level, and swing it back over into alignment with the bearing journals. Lower the back end down into the rear bearing, but maintain upward pressure on the sprocket.

8. Screw the tensioner in, drawing the sprocket and front end of the cam down until the cam rests in the front cam bearing journal. Or as close as it can get if valve springs & tappets are holding the cam up. No extra slack in the chain, but not 'tight'.

9) Install the cam bearing caps and torque tighten. Tightening the caps may draw the cam down against valve spring pressure. Watch timing chain slack as you draw the cam down, and tighten the tensioner periodically to prevent the chain from going slack enough to drop off the crank sprocket.

10) Repeat for the second cam.

11) Properly tension the timing chain, and double-check the cam timing.

It works. I've never 'fully' removed a cam just to shim the valve clearances in a Twin Cam. Properly done, there's never enough slack added to the timing chain loop to allow it to disengage from the crank sprocket, and the timing that was present at the start of the process isn't lost. Still, inspect the cam timing on a paranoid scale, but properly done, the timing shouldn't jump/ be lost. If the cam timing was wrong when you started, it will still be wrong when you finish... so always check the cam timing, and end with it being correct.

If all you do is shim the valves using this method, it doesn't take very long. I've showed the method to a few friends, who now use it as well.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Tim - trying your method, but can't seem to get enough slack to lift the front of the exhaust cam fully out of its seat, much less over the head bolt. I've fully removed the tensioner bolt at this point (though not the pin). Any thoughts or recommendations before I reassemble the bearings and remove the sprockets?

Henry

Henry

Esprit2 wrote:If all I'm doing is shimming a Twin Cam's valve clearances, then I've found the simple way to be...

1) Remove the cam bearing caps from one cam, freeing it.

2) Grasp the sprocket and apply firm upward pressure, lifting the front of the cam out of the front cam bearings as far as timing chain slack will allow.

3) Gradually unscrew the tensioner, allowing you to lift the sprocket & cam's forward end until the front cam journal is above the bearing in the head, then stop. Go no further than necessary.

4) Lift the back end of the cam higher than level, as necessary to allow that end to be swung to one side, over the head. Not far. Just a slight angle, far enough to find a resting spot for the cam. Lay the cam down on the head, while still maintaining upward pressure on the sprocket.

Ample use of foam or folded shop towel pads between the cam and head is recommended, although they're not 'required' if care is exercised.

Neither the chain nor it's mesh with the sprocket is rigid. There's enough flex available to allow the camshaft to be gently skewed slightly to one side or the other, as required to lay it at a slight angle across the head. NOT 90 degrees across the head. Just enough of an angle to find a spot, and far enough that the cam doesn't tend to drop back into the head. The sprocket is still in roughly the same location, just higher than normal, and slightly cocked with the tail end of the cam off to one side. There's just enough slack in the chain to allow the sprocket to rise as much as required, without ever introducing enough slack to allow the chain to come off either the cam or crank sprocket.

5) Maintain upward pressure on the sprocket & chain throughout the move. Once the back end of the cam is laid on the head, screw the tensioner back in only enough to pull the sprocket back down against upward hand-pressure, to a now 'crooked' rest position. Release the upward hand-pressure on the sprocket and chain only after the cam is at rest in it's new position.

Do what you need to do with tappets and shims, then...

6) Reverse the process. Grasp the sprocket and apply upward pressure while unscrewing the tensioner far enough to lift the cam to minimally clear of the head.

7) Lift the rear of the cam above level, and swing it back over into alignment with the bearing journals. Lower the back end down into the rear bearing, but maintain upward pressure on the sprocket.

8. Screw the tensioner in, drawing the sprocket and front end of the cam down until the cam rests in the front cam bearing journal. Or as close as it can get if valve springs & tappets are holding the cam up. No extra slack in the chain, but not 'tight'.

9) Install the cam bearing caps and torque tighten. Tightening the caps may draw the cam down against valve spring pressure. Watch timing chain slack as you draw the cam down, and tighten the tensioner periodically to prevent the chain from going slack enough to drop off the crank sprocket.

10) Repeat for the second cam.

11) Properly tension the timing chain, and double-check the cam timing.

It works. I've never 'fully' removed a cam just to shim the valve clearances in a Twin Cam. Properly done, there's never enough slack added to the timing chain loop to allow it to disengage from the crank sprocket, and the timing that was present at the start of the process isn't lost. Still, inspect the cam timing on a paranoid scale, but properly done, the timing shouldn't jump/ be lost. If the cam timing was wrong when you started, it will still be wrong when you finish... so always check the cam timing, and end with it being correct.

If all you do is shim the valves using this method, it doesn't take very long. I've showed the method to a few friends, who now use it as well.

Regards,

Tim Engel

Henry

69 Elan S4

65 Seven S2

69 Elan S4

65 Seven S2

- SENC

- Coveted Fifth Gear

- Posts: 1018

- Joined: 30 Dec 2015

Whether you take the cams clear off the head or what be aware that the chain will droop off the crank sprocket when chain is slack and ignition timing will be lost. Turn engine to firing point of #1 and make sure rotor points to # 1 terminal on the cap. If not let chain go slack and wiggle the rotor around til it lines up then put the cams back in lined up correctly hopping links as necessary. I never thought of Mr Engel's method but I like that!.

- Billmack

- Third Gear

- Posts: 257

- Joined: 30 Sep 2017

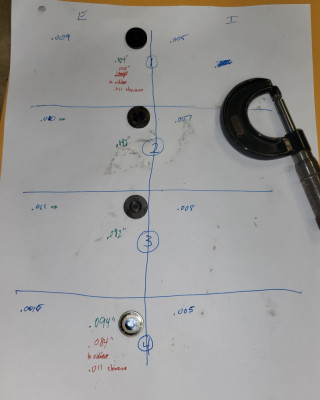

Finally had some time to get back to this job and since I haven't done this before would love a back-check before I order some shims. Here is my worksheet after retrieving the exhaust side shims. Blue is the clearance measured, green the shim size, red the calculated shim to achieve the target 0.11" clearance.

Thanks!

Thanks!

Henry

69 Elan S4

65 Seven S2

69 Elan S4

65 Seven S2

- SENC

- Coveted Fifth Gear

- Posts: 1018

- Joined: 30 Dec 2015

I agree with your numbers! Measure the new shims, they aren't always exact.

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1170

- Joined: 03 Oct 2012

Quart Meg Miles wrote:I agree with your numbers! Measure the new shims, they aren't always exact.

+1! When I was going through mine last year and having all that trouble with them (some of you may recall my 'reality check' post about it), I ordered some shims from one of the well-known suppliers and found some of them to be off by a thousandth or two. I used a micrometer that is calibrated annually for my job, so I felt confident about it. I brought it to the supplier's attention and they handled it superbly- told me that they sent out their mic for calibration and replaced the incorrect ones with some that I did get correct measurements from.

Oh, and be sure to thoroughly clean the shims before measuring them!

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2188

- Joined: 16 Nov 2015

NEVER do your shim math by using the marked thickness on a shim. Always measure all shims with an accurate micrometer. Do not use a caliper. If a used shim has any shallow depression worn into it's center, a caliper will bridge right over it, giving a false reading. A micromerter's small, round 'anvils' will fit into any center depression, and give you the shim's true 'working' thickness.

Measure the shim in the center, not near an edge. Especially if using used shims. The previous valve stem will have hammered a slight depression into one side of the shim. The shim's 'working' thickness is in the center, where it contacts the valve stem... down in the 'crater'. The rim will give you a 'false' thickness.

If you use a used shim, be certain to install it with any center depression facing DOWN, against the valve stem. Do your measurements and math perfectly, but install the shim depression side UP, and you'll get an unexpected, wrong clearance result.

The pocket in the top of the valve spring keeper that holds the shim may have an corner radius all around the inside perimeter of the bottom corner. Depending upon how high or low the end of the valve stem is cut, the shim's bottom side perimeter corner/ edge might contact the keeper's inside radius before it fully seats on the valve stem.

The correct OEM valve shims (no longer available from LOTUS) are supposed to be a loose 'diameter' fit in the keeper... you should be able to slide it side-to-side a little with light finger pressure. It should move far enough to center itself in the keeper's corner radius without bottoming out against it.

Modern shims come from different sources, and some are slightly larger or smaller in diameter than the originals. A slightly larege OD shim that's a snug fit in the keeper's ID can't move away from the keeper's radius. If the valve stem is cut low enough, the shim will contact the radius first, and not fully seat on the stem. In that case, you can measure and do the math perfectly time after time, but the resulting valve clearances will be wrong... too small. Aaargh!!

When you run into that, take the shim over to the bench grinder, and radius/ grind off the sharp perimeter edge on the bottom side (if it's a used shim, the 'bottom' is the side with the depression in the middle). The result doesn't have to be 'pretty' or perfectly uniform, just grind off the sharp corner edge... crudely radius it. Now, when you install the shim with both the perimeter radius & center depression down, it should firmly contact the end of the valve stem first. And your measurements and good math should give you the clearance you wanted.

Regards,

Tim Engel

Measure the shim in the center, not near an edge. Especially if using used shims. The previous valve stem will have hammered a slight depression into one side of the shim. The shim's 'working' thickness is in the center, where it contacts the valve stem... down in the 'crater'. The rim will give you a 'false' thickness.

If you use a used shim, be certain to install it with any center depression facing DOWN, against the valve stem. Do your measurements and math perfectly, but install the shim depression side UP, and you'll get an unexpected, wrong clearance result.

The pocket in the top of the valve spring keeper that holds the shim may have an corner radius all around the inside perimeter of the bottom corner. Depending upon how high or low the end of the valve stem is cut, the shim's bottom side perimeter corner/ edge might contact the keeper's inside radius before it fully seats on the valve stem.

The correct OEM valve shims (no longer available from LOTUS) are supposed to be a loose 'diameter' fit in the keeper... you should be able to slide it side-to-side a little with light finger pressure. It should move far enough to center itself in the keeper's corner radius without bottoming out against it.

Modern shims come from different sources, and some are slightly larger or smaller in diameter than the originals. A slightly larege OD shim that's a snug fit in the keeper's ID can't move away from the keeper's radius. If the valve stem is cut low enough, the shim will contact the radius first, and not fully seat on the stem. In that case, you can measure and do the math perfectly time after time, but the resulting valve clearances will be wrong... too small. Aaargh!!

When you run into that, take the shim over to the bench grinder, and radius/ grind off the sharp perimeter edge on the bottom side (if it's a used shim, the 'bottom' is the side with the depression in the middle). The result doesn't have to be 'pretty' or perfectly uniform, just grind off the sharp corner edge... crudely radius it. Now, when you install the shim with both the perimeter radius & center depression down, it should firmly contact the end of the valve stem first. And your measurements and good math should give you the clearance you wanted.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Mr Engel wrote 'If a used shim has any shallow depression worn into it's center' THROW IT AWAY, IT HAS PROBABLY BEEN TURNED OVER 100 TIMES. THEY ARE £1 EACH !

Mr Engel wrote 'If you use a used shim, be certain to install it with any center depression facing DOWN, against the valve stem. Do your measurements and math perfectly, but install the shim depression side UP, and you'll get an unexpected, wrong clearance result.' WHY USE A SHIM WITH DEPRESSIONS, THROW IT AWAY, IT HAS PROBABLY BEEN TURNED OVER 100 TIMES. THEY ARE £1 EACH !

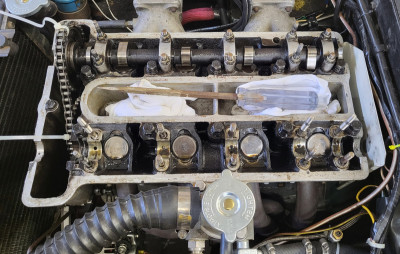

Mr Engel wrote 'The correct OEM valve shims (no longer available from LOTUS) are supposed to be a loose 'diameter' fit in the keeper... you should be able to slide it side-to-side a little with light finger pressure. It should move far enough to center itself in the keeper's corner radius without bottoming out against it. SEE MY PICTURES TO REITERATE Tims point.

Mr Engel wrote 'Modern shims come from different sources, and some are slightly larger or smaller in diameter than the originals. A slightly larege OD shim that's a snug fit in the keeper's ID can't move away from the keeper's radius. If the valve stem is cut low enough, the shim will contact the radius first, and not fully seat on the stem. In that case, you can measure and do the math perfectly time after time, but the resulting valve clearances will be wrong... too small. Aaargh!!

When you run into that, take the shim over to the bench grinder, and radius/ grind off the sharp perimeter edge on the bottom side (if it's a used shim, the 'bottom' is the side with the depression in the middle). The result doesn't have to be 'pretty' or perfectly uniform, just grind off the sharp corner edge... crudely radius it'

See my pictures to show modern, non chamfered shim on the right, and nicely chamfered original shim on the left. I cannot for the life of me understand why anyone would bother to use shims that are indented on both sides. You would then have to measure the indent and work out more complicated calculations than you would otherwise have to. They are £1 odd, just buy new ones and save the GRIEF.

Leslie

Mr Engel wrote 'If you use a used shim, be certain to install it with any center depression facing DOWN, against the valve stem. Do your measurements and math perfectly, but install the shim depression side UP, and you'll get an unexpected, wrong clearance result.' WHY USE A SHIM WITH DEPRESSIONS, THROW IT AWAY, IT HAS PROBABLY BEEN TURNED OVER 100 TIMES. THEY ARE £1 EACH !

Mr Engel wrote 'The correct OEM valve shims (no longer available from LOTUS) are supposed to be a loose 'diameter' fit in the keeper... you should be able to slide it side-to-side a little with light finger pressure. It should move far enough to center itself in the keeper's corner radius without bottoming out against it. SEE MY PICTURES TO REITERATE Tims point.

Mr Engel wrote 'Modern shims come from different sources, and some are slightly larger or smaller in diameter than the originals. A slightly larege OD shim that's a snug fit in the keeper's ID can't move away from the keeper's radius. If the valve stem is cut low enough, the shim will contact the radius first, and not fully seat on the stem. In that case, you can measure and do the math perfectly time after time, but the resulting valve clearances will be wrong... too small. Aaargh!!

When you run into that, take the shim over to the bench grinder, and radius/ grind off the sharp perimeter edge on the bottom side (if it's a used shim, the 'bottom' is the side with the depression in the middle). The result doesn't have to be 'pretty' or perfectly uniform, just grind off the sharp corner edge... crudely radius it'

See my pictures to show modern, non chamfered shim on the right, and nicely chamfered original shim on the left. I cannot for the life of me understand why anyone would bother to use shims that are indented on both sides. You would then have to measure the indent and work out more complicated calculations than you would otherwise have to. They are £1 odd, just buy new ones and save the GRIEF.

Leslie

- 512BB

- Coveted Fifth Gear

- Posts: 1205

- Joined: 24 Jan 2008

14 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 18 guests