bullet connector stuck in rev counter?

13 posts

• Page 1 of 1

I would try squirting some plusgas easing oil around the bullet, then wait a few hours and then with some needle nose pliers pull, or squeeze the connector and then pull to get it out. As a last resort if the wire comes away, drill out the old connector with a drill bit, just a little smaller than the diameter of a bullet connector.

The circuit is such that, inside, a wire goes from that connector, winds only a few times around a small transformer core as the primary and then go to the opposite bullet connector. It is done with opposit gender connectors so that you can pull out both white wires and plug them into each other to complete the ignition circuit to allow the car to run without the rev-counter.

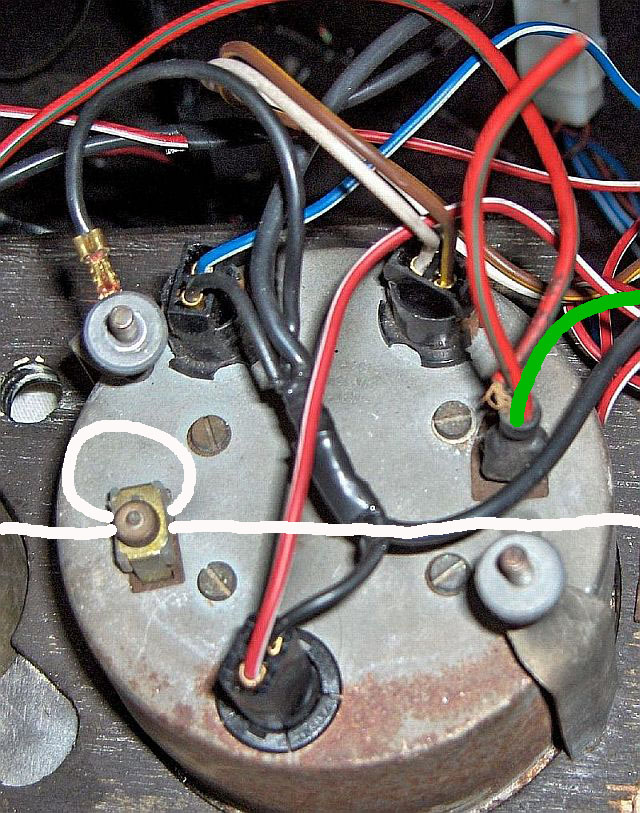

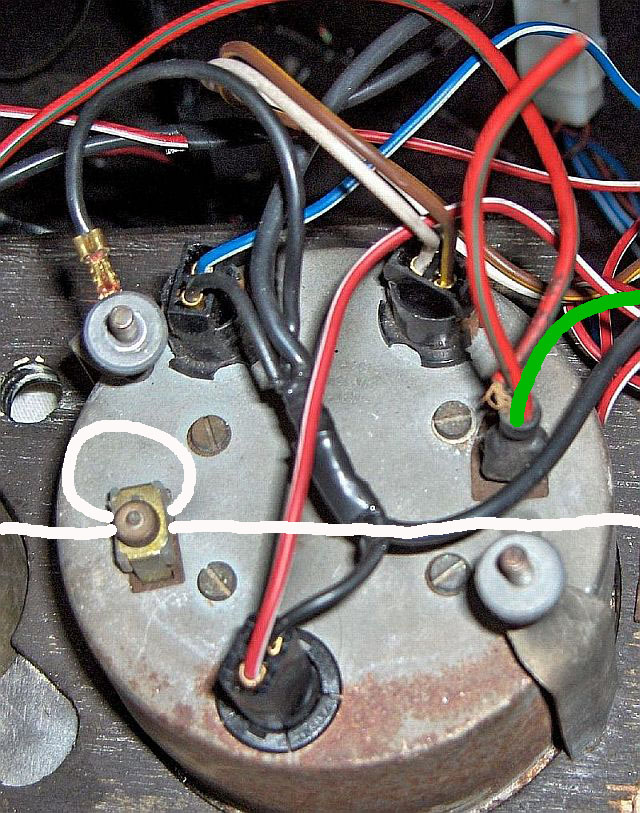

Earlier versions used a U shaped thin iron strip as the transformer core, with half the 'core' outside the can and the primary was wound around the outside portion of the core. Like this one:

The circuit is such that, inside, a wire goes from that connector, winds only a few times around a small transformer core as the primary and then go to the opposite bullet connector. It is done with opposit gender connectors so that you can pull out both white wires and plug them into each other to complete the ignition circuit to allow the car to run without the rev-counter.

Earlier versions used a U shaped thin iron strip as the transformer core, with half the 'core' outside the can and the primary was wound around the outside portion of the core. Like this one:

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Take care on the back of the rev counter you should have a female bullet and also a male bullet.

They should not be both female

Alan

They should not be both female

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3756

- Joined: 06 Dec 2008

Tom - the stub of wire still attached to the connector looks quite clean. It could be soldered onto a new wire and if well inuslated should last forever.

I only suggest this in case you should break the board the connector sits on. I cannot see it being a readily available part. If you do resort to this though, first, check continuity between the wire stub and the actual connector is good.

I only suggest this in case you should break the board the connector sits on. I cannot see it being a readily available part. If you do resort to this though, first, check continuity between the wire stub and the actual connector is good.

Hal Adams

Evora SR

Elan +2

Evora SR

Elan +2

-

HCA - Coveted Fifth Gear

- Posts: 1087

- Joined: 03 Jan 2020

HCA wrote:Not a problem - could you clean up a bit of the connector body to solder a wire onto?

Can't do it. The bullet connectors are inside a rubber shield which fastens somehow inside the tach. I'm pretty resolved to send it out for repair but may try drilling first.

Tom

- TomMull

- Second Gear

- Posts: 120

- Joined: 01 Oct 2018

I'm confident you should be able to proceed with the drilling, just do it upside down so that metallic schrapnels won't get too much into the gauge. Then you can use a small nail, also reversed head inside the hole, then to the side to pull the remains of the bullet out. Good luck !

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

If that problem was presented to me, I would select a self tapping screw of the appropriate size, and screw it in just far enough, leaving plenty on the outside to grip with a pair of pliers, and pull ! Out it should pop. If it doesn't, you did not use a large enough screw to grip the bullet.

Leslie

Leslie

- 512BB

- Coveted Fifth Gear

- Posts: 1205

- Joined: 24 Jan 2008

After a couple of days of messing around and hashing over ideas from this forum and also a local one, I finally got the bl**dy thing out. Thanks to photo above those to connectors are on either end of an induction loop (1 coil) so easy to make if I screwed it up. Armed with that knowledge I took the smallest drill I had that was just big enough not to fall to the bottom of the connector and made one pass on the drill press. That took out the slightest bit of brass so I repeated the drilling again 3 more times with successively bigger bits, and tugged on the connector each time. The last pass I made allowed the bullet to come right out. As you can see in the photo below, There was no corrosion. It would appear that it was the design of the aftermarket connector that held it in.

Tom

Tom

- TomMull

- Second Gear

- Posts: 120

- Joined: 01 Oct 2018

13 posts

• Page 1 of 1

Total Online:

Users browsing this forum: elanner and 41 guests