Horn Earth

11 posts

• Page 1 of 1

I think I know the answer although is seems very unlikely so wanting to check your thoughts.

I have the wire in place bridging the joint between rack and column and have continuity between the chassis and both ends of the wire although not through the column.

I have cleaned the knuckle back to clean metal and have continuity here although not in the column.

The only thing I can think of is that there is so much grime between the column and the knuckle that it is not contacting. Am I just being daft and missing something obvious?

Thanks, Steven

I have the wire in place bridging the joint between rack and column and have continuity between the chassis and both ends of the wire although not through the column.

I have cleaned the knuckle back to clean metal and have continuity here although not in the column.

The only thing I can think of is that there is so much grime between the column and the knuckle that it is not contacting. Am I just being daft and missing something obvious?

Thanks, Steven

- s28ven

- Second Gear

- Posts: 67

- Joined: 30 Sep 2014

I agree, I think you know the answer.

The column has to be earthed. If it is a fibre joint at the steering rack then it needs a link across it. If it a metal universal joint then it may not be necessary, but it does no harm to fit a link wire across the joint to be sure of a connection. Somewhere in that area you have a fault. A continuity meter or even just a battery and lamp method should locate it.

Eric in Burnley

S3SE Type 45

The column has to be earthed. If it is a fibre joint at the steering rack then it needs a link across it. If it a metal universal joint then it may not be necessary, but it does no harm to fit a link wire across the joint to be sure of a connection. Somewhere in that area you have a fault. A continuity meter or even just a battery and lamp method should locate it.

Eric in Burnley

S3SE Type 45

- ericbushby

- Coveted Fifth Gear

- Posts: 1353

- Joined: 13 Jun 2011

I have the bridging wire in place and have an earth at both ends and in the knuckle of the joint although not in the column itself.

I’ve connected a jump lead from the chassis to a clean bit of metal at the bottom of the column (above the UJ) and the horn works.

I’ve stripped the lower part of the column out and am going to need heat to get the knuckle off the column before cleaning up to splines and hopefully get continuity then

I’ve connected a jump lead from the chassis to a clean bit of metal at the bottom of the column (above the UJ) and the horn works.

I’ve stripped the lower part of the column out and am going to need heat to get the knuckle off the column before cleaning up to splines and hopefully get continuity then

- s28ven

- Second Gear

- Posts: 67

- Joined: 30 Sep 2014

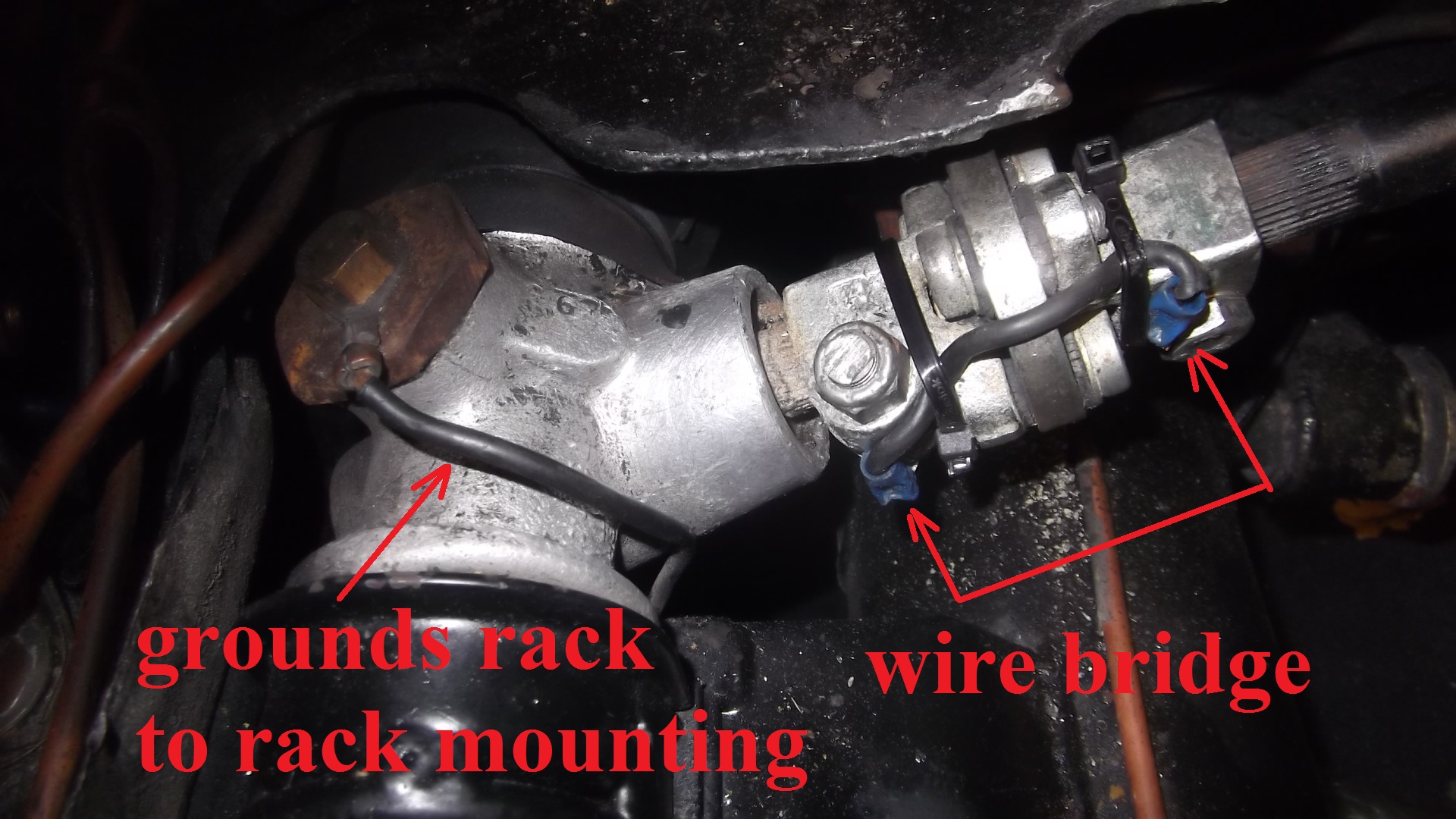

I thought from your initial post that you indeed had the wire that establishes ground connection between the bottom and the top of the column, but just in case you may want to check out the "wire bridge" on this photo from the forum (unless you have an all metal Ujoint) :

https://lotuselan.net/forums/viewtopic.php?f=38&t=26549

In any case one needs to get the ground up to the pencil contact inside the steering wheel horn button to get it to work, so it is a matter of following the ground up from the chassis to find out where a wire is cut or missing.

https://lotuselan.net/forums/viewtopic.php?f=38&t=26549

In any case one needs to get the ground up to the pencil contact inside the steering wheel horn button to get it to work, so it is a matter of following the ground up from the chassis to find out where a wire is cut or missing.

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

I have marked up the attached picture showing where I have an earth (red mark) and where I don’t (blue mark) I have cleaned the column to bare metal but it isn’t earthed.

I’ve got the uj and the column separated today so will clean up each site and prove continuity before re-fitting.

I’ve got the uj and the column separated today so will clean up each site and prove continuity before re-fitting.

- s28ven

- Second Gear

- Posts: 67

- Joined: 30 Sep 2014

With that same type of joint mine wasn't earthing even though the wire bridge was present. Close inspection revealed that the joint was assembled improperly which prevented the bolts from making the needed contact. I switched to the U-joint type and now all is well.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2188

- Joined: 16 Nov 2015

Put another Wire from bridge pinch bolt to Inner Column. Connect end of Wire to Inner Column with a Hose Clip

Alan

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3756

- Joined: 06 Dec 2008

When I bought my car there was an odd torsion spring with 2 legs:

It was attached to the chassis with the free leg rubbing against the steering column.

I had no idea what it did, until I removed it & the first time I tried to use the horn!

It was attached to the chassis with the free leg rubbing against the steering column.

I had no idea what it did, until I removed it & the first time I tried to use the horn!

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

On my +2 just under the steering wheel there was a sliding ring made from copper wire around the inner steer column shaft. Like a slip ring with an earth wire soldered to it to earth the Horn. It was as we say a "heath robinson" lash up but it worked

Alan

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3756

- Joined: 06 Dec 2008

11 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 45 guests