S1 Tach issues

17 posts

• Page 1 of 2 • 1, 2

Greetings,

I have read all the archive posts I could find but still have some questions. Now that the S1 is on the road I am sorting issues as I can. The tach did not work at all so I began looking into possible causes. After some investigating I pulled the tach and hand written on the back was "negative earth". I went on line and found a great set of instructions for reversing the polarity on the Lotus Cortina site. Mine had indeed been changed to negative ground but I wanted to return to positive as everything else was working just fine. After soldering the leads back to there original position I put it back together. On start up it jumped all over the place but at least it moved. Further investigation had me realize that the electric fuel pump was wired into the white wire circuit. I re-did this and then the tach was very steady but at least twice the proper RPM. I then looked at my MG tach and realized that the Lotus does not have the plastic isolator block that the white wire wraps around. Is this the problem? Could not dig one up in my spares so am stuck for now.

Also encountered a bit of a mystery with my speedo. It was also not working so I pulled the angle drive which appears to be just fine. In tracing the speedo cable I discovered poor routing and corrected this it seemed to now turn very easily where as before it was very stiff. With the angle drive off I inserted a short piece of speedo drive cable into the trasnsmission output drive and tried to turn it by hand to see if the drive gear was sheared. It felt solid. Put it all back together and on the test drive still no speedo. Perhaps I need to get the rear wheels up in the air so I can confirm if the out drive is working and then disconnect it at the speedo and see if it is turning there. On my old Vitesse it turned out to be a seazed speedo...anything else I should investigate?

Thanks so much

S.C

I have read all the archive posts I could find but still have some questions. Now that the S1 is on the road I am sorting issues as I can. The tach did not work at all so I began looking into possible causes. After some investigating I pulled the tach and hand written on the back was "negative earth". I went on line and found a great set of instructions for reversing the polarity on the Lotus Cortina site. Mine had indeed been changed to negative ground but I wanted to return to positive as everything else was working just fine. After soldering the leads back to there original position I put it back together. On start up it jumped all over the place but at least it moved. Further investigation had me realize that the electric fuel pump was wired into the white wire circuit. I re-did this and then the tach was very steady but at least twice the proper RPM. I then looked at my MG tach and realized that the Lotus does not have the plastic isolator block that the white wire wraps around. Is this the problem? Could not dig one up in my spares so am stuck for now.

Also encountered a bit of a mystery with my speedo. It was also not working so I pulled the angle drive which appears to be just fine. In tracing the speedo cable I discovered poor routing and corrected this it seemed to now turn very easily where as before it was very stiff. With the angle drive off I inserted a short piece of speedo drive cable into the trasnsmission output drive and tried to turn it by hand to see if the drive gear was sheared. It felt solid. Put it all back together and on the test drive still no speedo. Perhaps I need to get the rear wheels up in the air so I can confirm if the out drive is working and then disconnect it at the speedo and see if it is turning there. On my old Vitesse it turned out to be a seazed speedo...anything else I should investigate?

Thanks so much

S.C

- PDXjunkman

- First Gear

- Posts: 43

- Joined: 26 Jan 2011

There is a trimmer accessible from the back. There is no absolute scaling and its pretty coarse, probably to handle six-cylinder cars as well. My picture is of a later +2 model which has bullet connectors but I believe that the holes in the back are in the same place. Meter is shown the right way up.

Setting it accurately is a problem unless you have an independent instrument so your best bet is to find a friend and try to synchronise your engines at, say, 3000 rpm while you adjust it.

I have a problem as my transistor blew up and I couldn't find a replacement Germanium type. The available Silicon one I fitted works but isn't stable with temperature so I often cruise at an indicated 6,000 rpm! Has anyone got the right stuff, or even a correct Germanium transistor I could have? It was marked MT 59/A.

Meg

Setting it accurately is a problem unless you have an independent instrument so your best bet is to find a friend and try to synchronise your engines at, say, 3000 rpm while you adjust it.

I have a problem as my transistor blew up and I couldn't find a replacement Germanium type. The available Silicon one I fitted works but isn't stable with temperature so I often cruise at an indicated 6,000 rpm! Has anyone got the right stuff, or even a correct Germanium transistor I could have? It was marked MT 59/A.

Meg

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1278

- Joined: 03 Oct 2012

Thanks Meg,

I have held off playing with the calibration until I rule out that the missing isolator block, the small plastic item that the white wire wraps around, is not part of my problem. I have no idea if this is the case but I intend to find out just as soon as I can put my hands on one.

I have held off playing with the calibration until I rule out that the missing isolator block, the small plastic item that the white wire wraps around, is not part of my problem. I have no idea if this is the case but I intend to find out just as soon as I can put my hands on one.

- PDXjunkman

- First Gear

- Posts: 43

- Joined: 26 Jan 2011

S.C. and Meg

Some time back there was a dicussion re tach calibration on the forum and one way described to do it was to pass a lines household voltage lead thru the plastic isolater block on the tach. The alternating current wave spike of one pass thru the block gives the impulse required to drive the tach as follows;

On this side of the pond we operate at 120 volt, 60 cycles (per second), therefore;

60 cycles per second times 60 seconds per minute gives you 3600 cycles (REVOLUTIONS) per minute.

If your at 240 volt 50 cycle that gives you 3000 RPM.

Do it on the workbench with the cord to a worklite, pass one lead thru, and trim to the appropriate RPM.

I havent tried it mysef yet - I have issues to resolve yet with my S1 tach on Pertronex ignition . Another winter project. Theoretically it makes scence.

Bill - 26/0538

Keep your stick on the ice!

Some time back there was a dicussion re tach calibration on the forum and one way described to do it was to pass a lines household voltage lead thru the plastic isolater block on the tach. The alternating current wave spike of one pass thru the block gives the impulse required to drive the tach as follows;

On this side of the pond we operate at 120 volt, 60 cycles (per second), therefore;

60 cycles per second times 60 seconds per minute gives you 3600 cycles (REVOLUTIONS) per minute.

If your at 240 volt 50 cycle that gives you 3000 RPM.

Do it on the workbench with the cord to a worklite, pass one lead thru, and trim to the appropriate RPM.

I havent tried it mysef yet - I have issues to resolve yet with my S1 tach on Pertronex ignition . Another winter project. Theoretically it makes scence.

Bill - 26/0538

Keep your stick on the ice!

Bill Rathlef

Vancouver Island, Canada

"Keep your stick on the ice, boys."

Vancouver Island, Canada

"Keep your stick on the ice, boys."

-

Bill - Fourth Gear

- Posts: 709

- Joined: 05 Oct 2003

S.C. Memory says the white wire wraps around a bent metal strip, embedded in plastic, that pushes into a similar metal strip in the tach. This completes a pulse transformer that is part of a Blocking Oscillator, triggering it to pump standard pulses of current through the meter. The bit of plastic isn't part of the circuit or insulation, as we are only dealing with battery voltage here, but helps retain it in position.

Bill. I'll be surprised if that works as the change of current is so slow compared to the abrupt interruption of the much higher coil current, unless your "worklite" isn't just a simple bulb. But if it does work it is a much better solution than mine. The power companies are allowed to vary their frequency a little to cope with loads; it used to be 2% but now we are linked to the EU it may be less. H&S precludes me from recommending it but if you know what you are doing S.C. let us know how you get on!

I'm sure some of the Dwell Meters you used to be able to buy also read engine speed, could anyone lend one?

Meg

26/4088 White S1/2

Bill. I'll be surprised if that works as the change of current is so slow compared to the abrupt interruption of the much higher coil current, unless your "worklite" isn't just a simple bulb. But if it does work it is a much better solution than mine. The power companies are allowed to vary their frequency a little to cope with loads; it used to be 2% but now we are linked to the EU it may be less. H&S precludes me from recommending it but if you know what you are doing S.C. let us know how you get on!

I'm sure some of the Dwell Meters you used to be able to buy also read engine speed, could anyone lend one?

Meg

26/4088 White S1/2

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1278

- Joined: 03 Oct 2012

The bit of plastic just holds the loop in place so it doesn't get chafed. So it would be fairly easy to make up a copy in wood. The important bit is the 'U' shaped steel clip which holds the block in place. I imagine it must be steel (magnetisable), not brass or aluminium, for good inductive coupling (as used in the construction of transformers, which is basically what this is). The loop has to run through in the right direction.

I too have heard of the trick of using the house mains for calibration at 3000 or 1500 rpm (UK supplies) with full or half wave rectification, but haven't tried it. If I did, I think I would get hold of a 12 volt transformer, put it in a case with the secondary cables lead out of the case. That way, I could play about with the AC voltage safely. I would expect that I would need to load the secondary so that it passed 1 or 2 amps to make the rev counter work, perhaps more, so I would choose a beefy enough transformer and use 4 amp diodes. As I say I've never done it. I can see the adavantage is it doesn't require much equipment to do it, but I am much more concerned to get my rev counter right at max revs and correct idle speed, and I can assure you these meters are not very linear in their response, even with careful fettling, but you can get it spot on at any two speeds. I've seen a suggestion on the internet that you can download a tone generator for free and use the audio output of your computer, connected to an amplifier, which sounds promising.

You can buy a digital test meter that has dwell and tacho functions for a little over ?20, which would save a lot of messing about and would probably be good in terms of accuracy.

An alternative to the MT59A germanium transistor is the GET114 made by Mullard (15 volt, 200 mw, hfe or gain 30-80). These are available on ebay for ?2.99, also from specialists. The GET114 was also used by Lucas in these revcounters. I don't know if a silicon transistor could be substituted without changing some of the resistors, perhaps. Nothing to lose by trying it.

So far as the speedo is concerned, I would start by disconnecting the cable at the speedo end and seeing if it spins ok when the propshaft turns, as I would find it easier to do. Might have to take the speedo out, but probably easier than grovelling under the car.

regards

Richard

I too have heard of the trick of using the house mains for calibration at 3000 or 1500 rpm (UK supplies) with full or half wave rectification, but haven't tried it. If I did, I think I would get hold of a 12 volt transformer, put it in a case with the secondary cables lead out of the case. That way, I could play about with the AC voltage safely. I would expect that I would need to load the secondary so that it passed 1 or 2 amps to make the rev counter work, perhaps more, so I would choose a beefy enough transformer and use 4 amp diodes. As I say I've never done it. I can see the adavantage is it doesn't require much equipment to do it, but I am much more concerned to get my rev counter right at max revs and correct idle speed, and I can assure you these meters are not very linear in their response, even with careful fettling, but you can get it spot on at any two speeds. I've seen a suggestion on the internet that you can download a tone generator for free and use the audio output of your computer, connected to an amplifier, which sounds promising.

You can buy a digital test meter that has dwell and tacho functions for a little over ?20, which would save a lot of messing about and would probably be good in terms of accuracy.

An alternative to the MT59A germanium transistor is the GET114 made by Mullard (15 volt, 200 mw, hfe or gain 30-80). These are available on ebay for ?2.99, also from specialists. The GET114 was also used by Lucas in these revcounters. I don't know if a silicon transistor could be substituted without changing some of the resistors, perhaps. Nothing to lose by trying it.

So far as the speedo is concerned, I would start by disconnecting the cable at the speedo end and seeing if it spins ok when the propshaft turns, as I would find it easier to do. Might have to take the speedo out, but probably easier than grovelling under the car.

regards

Richard

- ricarbo

- Third Gear

- Posts: 269

- Joined: 14 Apr 2010

Thanks so much for all the helpful info. Here is an update of sorts. With regards to the speedo I believe the problem is the spindle in the angle drive is slipping. The internal end is not a square drive as is the output and it appears to have come loose. I guess the next step is to dismantle the unit and fix the spindle properly.

As for the tach now that it appears that the insolator block has no effect on the calibration issue I will use my meter that has RPM and try the calibration set screw.

Cheers

S.C

As for the tach now that it appears that the insolator block has no effect on the calibration issue I will use my meter that has RPM and try the calibration set screw.

Cheers

S.C

- PDXjunkman

- First Gear

- Posts: 43

- Joined: 26 Jan 2011

Greetings,

It was a bit tricky but I did get the angle drive apart. Used a tiny carbide burr to grind the staking points on the cover ...finally after some monkey business it did come off. The rest proved straight forward. I completely de-greased the spindle and the bevel gear then used J-B Weld to fix the two parts together. Seems like it should work....we will see.

Pics before and after epoxy.

S.C

It was a bit tricky but I did get the angle drive apart. Used a tiny carbide burr to grind the staking points on the cover ...finally after some monkey business it did come off. The rest proved straight forward. I completely de-greased the spindle and the bevel gear then used J-B Weld to fix the two parts together. Seems like it should work....we will see.

Pics before and after epoxy.

S.C

- PDXjunkman

- First Gear

- Posts: 43

- Joined: 26 Jan 2011

Good work S.C. and thank you Richard for your confirmation and pointer to the Ge device. It stimulated an exciting idea for a calibrator but as I'm being whisked off to sun, se* and sangria it will be a few weeks before I can share it. Meg

26/4088 White S1/2

26/4088 White S1/2

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1278

- Joined: 03 Oct 2012

My right angle drive did the same thing. i think the short bit of square section cable that goes into the gearbox is called a quill. Anyway it had become detached. I stuck it back into the right angle drive with some Loctite, which has worked so far. I believe new ones are available, for about ?50.

Good luck.

regards

richard

Good luck.

regards

richard

- ricarbo

- Third Gear

- Posts: 269

- Joined: 14 Apr 2010

PDXjunkman wrote:Thanks Meg,

I have held off playing with the calibration until I rule out that the missing isolator block, the small plastic item that the white wire wraps around, is not part of my problem. I have no idea if this is the case but I intend to find out just as soon as I can put my hands on one.

SC, consider calling Nisonger's. I just got my tach converted, and I see they have completely removed the external bridge and replaced it with a blanking plate with a new signal wire coming out through the plate. Perhaps they have some of the bridge components they have removed from conversions they have done.

If all you need is the nylon block bit, I think I have one that is surplus to my needs now (once I confirm my tach actually works tomorrow). These probably get thrown out with the old loom as they are threaded on to the wiring and can only be removed by cutting the wire. I have the tach out this evening and can remove the block and mail it to you. Shoot me your address in a PM or email and I will mail it to you. Cost is (as per Alex's practice) a suitable donation to charity of your choice.

HTH

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 2063

- Joined: 03 Sep 2007

Those tachs are notorious for not reading accuratly and were used on virtually every British car through most of the 60's. The block and bridge is probably available on e-bay if you do a bit of hunting in Smiths rather than Lotus. Its common for the tach not to work with electronic ignition.

The Sprite guys sometimes swap the guts out of a later tach. That is what I intend to do.

Kurt.

The Sprite guys sometimes swap the guts out of a later tach. That is what I intend to do.

Kurt.

- nomad

- Coveted Fifth Gear

- Posts: 1172

- Joined: 05 May 2012

I have established that simple rectified mains (line) waveforms aren't fast enough to trigger a Tach. In fact the one I have needs 4,000 Amps/sec edges to operate and so will only operate on the firing edge of the coil current. This trace shows the minimum I needed for operation, zero current is at the top (I'm only using a resistor and ignore the round bottom, that's the battery charger waveform which triggers the test and powers the "coil"):

And to prove it can be done here is Nicolacoltro's tachometer being checked before I post it to her.

I'm still considering the best configuration of the calibration circuit but if it's too simple it won't be versatile. Watch this space.

And to prove it can be done here is Nicolacoltro's tachometer being checked before I post it to her.

I'm still considering the best configuration of the calibration circuit but if it's too simple it won't be versatile. Watch this space.

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1278

- Joined: 03 Oct 2012

stugilmour wrote:SC, consider calling Nisonger's.

. . . or on this side of the pond, contact Speedy Cables. They converted and calibrated my tach when I went to negative earth to install an alternator. The instrument came back as good as new - or better as it is now accurate!!

Mechanical Engineer, happily retired!

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Galwaylotus - Coveted Fifth Gear

- Posts: 1348

- Joined: 01 May 2006

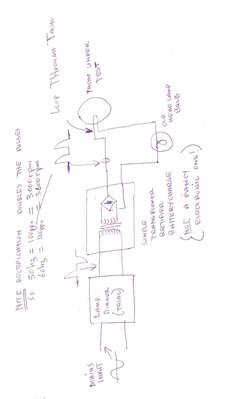

Hi All

Getting a pulse from mains frequency which is quite accurate in most countries (50Hz or 60Hz) is a good source of tacho calibration

It may be possible to use a simple battery charger the transformer and rectifier type ( not a fancy electronic controlled one)

and to feed it from a triac based light dimmer or drill speed controller. This will give current pulses with a very fast rise.

Load the battery charger up with a old headlamp bulb and put the tacho loop in series with this.

I have not tried this myself but I think it should work. Also the battery charger reduces the voltage to a safe value so no messing around with live wires.

with a 4 cylinder engine there are 2 pulses required per rev with this idea rectification doubles the pulses so 50Hz gives 100pps from the battery charger or 3000rpm.

I have attached a sketch-- if someone tries it let me know!!

best of luck

Bob

Getting a pulse from mains frequency which is quite accurate in most countries (50Hz or 60Hz) is a good source of tacho calibration

It may be possible to use a simple battery charger the transformer and rectifier type ( not a fancy electronic controlled one)

and to feed it from a triac based light dimmer or drill speed controller. This will give current pulses with a very fast rise.

Load the battery charger up with a old headlamp bulb and put the tacho loop in series with this.

I have not tried this myself but I think it should work. Also the battery charger reduces the voltage to a safe value so no messing around with live wires.

with a 4 cylinder engine there are 2 pulses required per rev with this idea rectification doubles the pulses so 50Hz gives 100pps from the battery charger or 3000rpm.

I have attached a sketch-- if someone tries it let me know!!

best of luck

Bob

- bob_rich

- Fourth Gear

- Posts: 564

- Joined: 06 Aug 2009

17 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 13 guests