Tachometer reading too high, Europa S2

17 posts

• Page 1 of 2 • 1, 2

My car is a 1968 Europa S2, which of course isn't an Elan, but I figured the problem would be the same with an Elan. My tachometer is reading more revs than the engine is actually doing. If I recall correctly, it's reading 50% too much. The tachometer was checked/restored by a Smiths expert, who regretfully has passed away. The coil is a Lucas Sport and the distributor is an original Ducellier on the Renault engine. I use an electronic fuel pump on the ignition circuit. What might be the cause and solution of this error?

- max

- New-tral

- Posts: 5

- Joined: 19 Dec 2010

Hi Max

need a bit more info to be helpful. Is the tacho an RV1 type with an external or internal current loop?

the number is usually on the dial just below the centre of the pointer. and the external currernt loop type is the one where a small loop can be seen on the rear of the tacho usually held on with a small U bracket and a nut. An internal current loop has two wires that go into the tacho one with a male and the other with a female bullet.

Might be able to help if new a bit more about it

best of luck

Bob

need a bit more info to be helpful. Is the tacho an RV1 type with an external or internal current loop?

the number is usually on the dial just below the centre of the pointer. and the external currernt loop type is the one where a small loop can be seen on the rear of the tacho usually held on with a small U bracket and a nut. An internal current loop has two wires that go into the tacho one with a male and the other with a female bullet.

Might be able to help if new a bit more about it

best of luck

Bob

- bob_rich

- Fourth Gear

- Posts: 564

- Joined: 06 Aug 2009

Max

I was able to successfully adjust my RVI tach (the earlier one with the wire loop connection as Bob describes above). There is an adjustment potentiometer inside the case. Adjustment is quite sensitive, and done by turning the pot with a small screwdriver. I had to remove the tach, undo two of the screws on the back case, remove the instrument, drill a 1/4" hole in the back case, and re-assemble the unit.

Adjustment was done by connecting to the car wiring and running at different engine speeds. Much easier with a helper to set the throttle to a desired engine speed on the tuning tach so you can concentrate on holding the Smiths unit and getting the adjustment done correctly. Bit iterative to get it reading reasonably over the rev range; I focused on getting it right from about 3500 to 6500.

HTH

I was able to successfully adjust my RVI tach (the earlier one with the wire loop connection as Bob describes above). There is an adjustment potentiometer inside the case. Adjustment is quite sensitive, and done by turning the pot with a small screwdriver. I had to remove the tach, undo two of the screws on the back case, remove the instrument, drill a 1/4" hole in the back case, and re-assemble the unit.

Adjustment was done by connecting to the car wiring and running at different engine speeds. Much easier with a helper to set the throttle to a desired engine speed on the tuning tach so you can concentrate on holding the Smiths unit and getting the adjustment done correctly. Bit iterative to get it reading reasonably over the rev range; I focused on getting it right from about 3500 to 6500.

HTH

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 2063

- Joined: 03 Sep 2007

bob_rich wrote:Is the tacho an RV1 type with an external or internal current loop?

My tacho has the external wire loop.

stugilmour wrote:Max

I was able to successfully adjust my RVI tach (the earlier one with the wire loop connection as Bob describes above). There is an adjustment potentiometer inside the case. Adjustment is quite sensitive, and done by turning the pot with a small screwdriver. I had to remove the tach, undo two of the screws on the back case, remove the instrument, drill a 1/4" hole in the back case, and re-assemble the unit.

Adjustment was done by connecting to the car wiring and running at different engine speeds. Much easier with a helper to set the throttle to a desired engine speed on the tuning tach so you can concentrate on holding the Smiths unit and getting the adjustment done correctly. Bit iterative to get it reading reasonably over the rev range; I focused on getting it right from about 3500 to 6500.

Interesting solution, I'll try that if there's no easier solution to the problem.

Isn't there a chance that the fuel pump is affecting the signal? I mean, it might somehow introduce more pulses in the wiring loop. Now I should have been able to describe how it's wired, but I'll have to check that, as it was a while since I worked on the car. It is wired together with the ignition to make it start when the ignition is on.

Last edited by max on Mon Dec 20, 2010 11:21 am, edited 1 time in total.

- max

- New-tral

- Posts: 5

- Joined: 19 Dec 2010

Hi Max,

I'm not sure that the electric pump would affect the rev counter, I have a facet one on my Elan and it didn't seem to make any significant difference.

One thing that did occur to me is that you could try running the engine and then disconnecting the power to the pump (maybe an anti-theft switch in the circuit ?). The engine will run for a few moments with the fuel already in the float chamber and if the pump was making any difference then you should see a drop on the tach as soon as the pump was switched off.

Calibration as mentioned above isn't too bad, just very fiddly. I bought an aftermarket electronic rev counter that I could clip across the coil terminals to get a reading which seemed sensible, then adjusted mine to match it. Mine was well out, I had an elan that would rev to 8000 (no, not really)

Brian

I'm not sure that the electric pump would affect the rev counter, I have a facet one on my Elan and it didn't seem to make any significant difference.

One thing that did occur to me is that you could try running the engine and then disconnecting the power to the pump (maybe an anti-theft switch in the circuit ?). The engine will run for a few moments with the fuel already in the float chamber and if the pump was making any difference then you should see a drop on the tach as soon as the pump was switched off.

Calibration as mentioned above isn't too bad, just very fiddly. I bought an aftermarket electronic rev counter that I could clip across the coil terminals to get a reading which seemed sensible, then adjusted mine to match it. Mine was well out, I had an elan that would rev to 8000 (no, not really)

Brian

-

UAB807F - Fourth Gear

- Posts: 730

- Joined: 20 Dec 2010

Hi Max

From your post I get the impression that the tacho has just been fitted and is over reading steadily and consistently by around 50% so 900rpm tickover is say reading 1350rpm and prorata as engine revs rise. If so it does not sound like interference from any electrical gadget in the car. If the reading is erratic then it could be related to interference on the voltage to the tacho but fans and heater motors would be much worse than a facet pump in this regard. The adjuster inside as the post by Stu suggested may sort out a general over reading.

You mentioned a sports coil they have higher current so might trigger tacho more than once with a given ignition pulse could be worth trying 1 less turn through the external current link as an idea. Also is the wire through the current loop the correct way? perhaps reversing it might effect tacho reading.

Another possibility could be points bouncing on closing after dwell period-- is points gap OK and are points in general good order?

Hope this helps best of luck

Bob

From your post I get the impression that the tacho has just been fitted and is over reading steadily and consistently by around 50% so 900rpm tickover is say reading 1350rpm and prorata as engine revs rise. If so it does not sound like interference from any electrical gadget in the car. If the reading is erratic then it could be related to interference on the voltage to the tacho but fans and heater motors would be much worse than a facet pump in this regard. The adjuster inside as the post by Stu suggested may sort out a general over reading.

You mentioned a sports coil they have higher current so might trigger tacho more than once with a given ignition pulse could be worth trying 1 less turn through the external current link as an idea. Also is the wire through the current loop the correct way? perhaps reversing it might effect tacho reading.

Another possibility could be points bouncing on closing after dwell period-- is points gap OK and are points in general good order?

Hope this helps best of luck

Bob

- bob_rich

- Fourth Gear

- Posts: 564

- Joined: 06 Aug 2009

Max

Check your wiring configuration for the pump carefully & thoroughly, but like Brian I expect it is OK. The pump ideally will be off of a "hot in run or start - fused" circuit, which is generally green. The ignition is typically "hot in run or start - unfused", which is white. Not sure for a Europa, but typically an electric pump is user added in the Elan & Plus 2, so wiring maybe different depending on who did the job.

Typically you do not want any accessory load on the ignition wire from key through the tach inductive bridge loop to the +ve coil, although the temp & fuel gauge voltage stabilizer & ignition dash light may be in there somewhere. This includes powering of electronic ignition modules, which can cause the RVI tach to act up. You will also want some sort of fuse protection for the aftermarket fuel pump, mainly because the power wire may be exposed to road crap, heat, etc. and has a fairly long run depending on the fuse location. Common spots to take fuel pump power would be the white supply wires to the fuse box with it's own dedicated fuse or ignition switch. In any case, if not directly connected to the inductive loop coil wire, should not be an issue regarding tach reading problem. Of course, Brian's suggestion should eliminate this as an issue if you are unsure.

Bob's suggestion regarding the high output coil is a good one, and easy to try without disassembling the tach. My Plus 2 Workshop Manual, buried within the "Service Notes" section so not obvious, mentions taking the loop out of the tach bridge if a high output coil is fitted. Mine works fine with Pertronix electronic ignition & high output coil with NO loop; i.e. the wire runs straight through the tach inductive bridge as per the Service Notes suggestion. Was set up this way when I got the car, so I just left it that way during my re-wire. However Service Notes describes the HO coil malfunction a bit differently than your problem... "The characteristic in this case is that the needle will stick around 3000 rpm", so this may not be your issue.

Also like Bob, curious if you just fitted the tach after its service, or if this has been a problem for a while. I would have assumed the service tech would have a pulse generator to bench test the tach head and dial in the adjustment pot pretty closely. However, I have never sent one in for service, so who knows, maybe it has to be adjusted in situ in most/all cases? In any case, this is the adjustment procedure for the instrument as designed, so wouldn't look for another external fix after checking the wiring is all OK.

The adjustment procedure of the RVI is pretty straight forward. I found some web pages with good directions & photo's of the tach guts, etc., but having difficulty finding the correct link. Only real point of caution I recall is to make sure you undo the correct two screws on the tach bucket so the guts don't come off of the tach face. Take your time and ask more questions if not sure and we can walk you through it.

Also recommended to examine physical condition of the output capacitor while you have the tach apart. I was able to adjust mine, so did not change any components. Assuming your's is OK as you have had the unit serviced already.

I have added some additional stuff in a word document from the 'net that might help.

HTH Welcome aboard. Where are you located?

Check your wiring configuration for the pump carefully & thoroughly, but like Brian I expect it is OK. The pump ideally will be off of a "hot in run or start - fused" circuit, which is generally green. The ignition is typically "hot in run or start - unfused", which is white. Not sure for a Europa, but typically an electric pump is user added in the Elan & Plus 2, so wiring maybe different depending on who did the job.

Typically you do not want any accessory load on the ignition wire from key through the tach inductive bridge loop to the +ve coil, although the temp & fuel gauge voltage stabilizer & ignition dash light may be in there somewhere. This includes powering of electronic ignition modules, which can cause the RVI tach to act up. You will also want some sort of fuse protection for the aftermarket fuel pump, mainly because the power wire may be exposed to road crap, heat, etc. and has a fairly long run depending on the fuse location. Common spots to take fuel pump power would be the white supply wires to the fuse box with it's own dedicated fuse or ignition switch. In any case, if not directly connected to the inductive loop coil wire, should not be an issue regarding tach reading problem. Of course, Brian's suggestion should eliminate this as an issue if you are unsure.

Bob's suggestion regarding the high output coil is a good one, and easy to try without disassembling the tach. My Plus 2 Workshop Manual, buried within the "Service Notes" section so not obvious, mentions taking the loop out of the tach bridge if a high output coil is fitted. Mine works fine with Pertronix electronic ignition & high output coil with NO loop; i.e. the wire runs straight through the tach inductive bridge as per the Service Notes suggestion. Was set up this way when I got the car, so I just left it that way during my re-wire. However Service Notes describes the HO coil malfunction a bit differently than your problem... "The characteristic in this case is that the needle will stick around 3000 rpm", so this may not be your issue.

Also like Bob, curious if you just fitted the tach after its service, or if this has been a problem for a while. I would have assumed the service tech would have a pulse generator to bench test the tach head and dial in the adjustment pot pretty closely. However, I have never sent one in for service, so who knows, maybe it has to be adjusted in situ in most/all cases? In any case, this is the adjustment procedure for the instrument as designed, so wouldn't look for another external fix after checking the wiring is all OK.

The adjustment procedure of the RVI is pretty straight forward. I found some web pages with good directions & photo's of the tach guts, etc., but having difficulty finding the correct link. Only real point of caution I recall is to make sure you undo the correct two screws on the tach bucket so the guts don't come off of the tach face. Take your time and ask more questions if not sure and we can walk you through it.

Also recommended to examine physical condition of the output capacitor while you have the tach apart. I was able to adjust mine, so did not change any components. Assuming your's is OK as you have had the unit serviced already.

I have added some additional stuff in a word document from the 'net that might help.

HTH Welcome aboard. Where are you located?

- Attachments

-

Fast tach and tach operation & instuments.doc

Fast tach and tach operation & instuments.doc- Some instument notes from the net

- (488 KiB) Downloaded 8304 times

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 2063

- Joined: 03 Sep 2007

UAB807F wrote:One thing that did occur to me is that you could try running the engine and then disconnecting the power to the pump (maybe an anti-theft switch in the circuit ?). The engine will run for a few moments with the fuel already in the float chamber and if the pump was making any difference then you should see a drop on the tach as soon as the pump was switched off.

That's a good advice. I'll try that when I get the chance to work on the car.

bob_rich wrote:From your post I get the impression that the tacho has just been fitted and is over reading steadily and consistently by around 50% so 900rpm tickover is say reading 1350rpm and prorata as engine revs rise. If so it does not sound like interference from any electrical gadget in the car. If the reading is erratic then it could be related to interference on the voltage to the tacho but fans and heater motors would be much worse than a facet pump in this regard. The adjuster inside as the post by Stu suggested may sort out a general over reading.

You mentioned a sports coil they have higher current so might trigger tacho more than once with a given ignition pulse could be worth trying 1 less turn through the external current link as an idea. Also is the wire through the current loop the correct way? perhaps reversing it might effect tacho reading.

My idea about the pump is that it would have a pulsating current, just like the ignition signal, which would somehow leak to the signal loop. But then the error would probably change while running the car...

I'll give that a try, adjusting the wire loop through the external current link. It would be really nice if it's that easy. By the way, I think the wire loop on my tacho is held only by a metal U-clip and a nut. Is there supposed to be some kind of a plastic piece, which the wire is supposed to be guided through? I have a vague memory of having seen something like that.

stugilmour wrote:Also like Bob, curious if you just fitted the tach after its service, or if this has been a problem for a while. I would have assumed the service tech would have a pulse generator to bench test the tach head and dial in the adjustment pot pretty closely. However, I have never sent one in for service, so who knows, maybe it has to be adjusted in situ in most/all cases? In any case, this is the adjustment procedure for the instrument as designed, so wouldn't look for another external fix after checking the wiring is all OK.

The adjustment procedure of the RVI is pretty straight forward. I found some web pages with good directions & photo's of the tach guts, etc., but having difficulty finding the correct link. Only real point of caution I recall is to make sure you undo the correct two screws on the tach bucket so the guts don't come off of the tach face. Take your time and ask more questions if not sure and we can walk you through it.

Also recommended to examine physical condition of the output capacitor while you have the tach apart. I was able to adjust mine, so did not change any components. Assuming your's is OK as you have had the unit serviced already.

I have added some additional stuff in a word document from the 'net that might help.

HTH Welcome aboard. Where are you located?

The car had a full restoration a few years ago, then it was left in the garage for a while. My memory says that the tacho worked fine before that, but then the car was dismantled for a respray. Nothing is supposed to have been altered and I really can't see why the gauge guy would calibrate it for a three cylinder engine. Strange.

It would be great if you could find the pictures of the tacho internals. I'll check that Word document too.

Thanks! I haven't seen this forum until now, and I spent a lot of time scanning the Internet during the restoration 2004-06. I live in Sweden.

- max

- New-tral

- Posts: 5

- Joined: 19 Dec 2010

Hi Max

As I recall the external current loop tacho did have a small metal clip that held the loop. Perhaps a good clean up and firmly tighten down might help? Mine is an internal loop tacho and so have no pictures Unfortunately I only have pictures of the internal loop tacho which, internally is quite different. The link below is a book review and usefully it has a bit of info on the RV1 tachos as review pages

hope this helps

best of luck

Bob

http://books.google.co.uk/books?id=9kQ9 ... &q&f=false

As I recall the external current loop tacho did have a small metal clip that held the loop. Perhaps a good clean up and firmly tighten down might help? Mine is an internal loop tacho and so have no pictures Unfortunately I only have pictures of the internal loop tacho which, internally is quite different. The link below is a book review and usefully it has a bit of info on the RV1 tachos as review pages

hope this helps

best of luck

Bob

http://books.google.co.uk/books?id=9kQ9 ... &q&f=false

- bob_rich

- Fourth Gear

- Posts: 564

- Joined: 06 Aug 2009

paddy wrote:paddy wrote:It sounds like it's calibrated for a 6 cylinder engine.

Of course I'm wrong - it would be reading low by 1/3.

Paddy

So then . . . it must be calibrated for a 2.67 cylinder engine!!

Mechanical Engineer, happily retired!

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Galwaylotus - Coveted Fifth Gear

- Posts: 1348

- Joined: 01 May 2006

Done it many times myself.

Mechanical Engineer, happily retired!

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Galwaylotus - Coveted Fifth Gear

- Posts: 1348

- Joined: 01 May 2006

Hi Max

This link has some photo's, although it is not the site I was trying to find. Don't worry about a lot of the discussion as it is not relevant to your problem, although the author describes the calibration procedure and has a cool idea to calibrate using a cheap charger. The calibration may be enough to "fool" the tach reading for different engine cylinder count, but I don't believe this is its primary purpose. I understand its primary purpose is to resolve exactly your problem, and to allow adjustment as some of the components age and change values or to take up slop in the precision of the components even when new. Your tach could have been out of calibration all along; I know mine was by about 1000 rpm but I did not realize it. All good now compared to the clip-on, and was able to confirm comparing GPS speed readings and rpm's in fourth gear and calculating rpm's based on diff ratio.

Your tach may be slightly different than the one in the photo's. For the Plus 2 I have two indicator lights in the bottom of the tach housing. This one appears to have only one. Not sure for Europa. In any case, not an issue.

http://mgaguru.com/mgtech/electric/et202c.htm

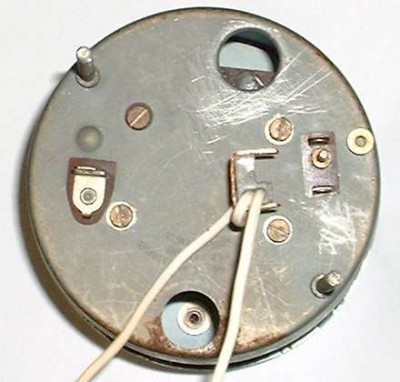

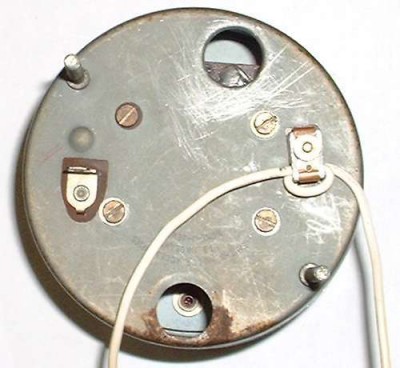

Here are some of the relevant photos from the above site. I don't think the plastic dingus will really matter all that much in terms of tach calibration, but who knows. Reading the web site again, I see the author points out the plastic piece is in effect part of the loom, so could easily have been missed during your re-wire; I recall I almost missed it on my car until I cut it out of the old loom and threaded it into the new wiring. Still a good idea to make sure the white coil wire cannot possibly wear through and short to ground on the tach bucket, as this will halt all forward progress of the car in a rather dramatic fashion with attendant sparks and smoke.

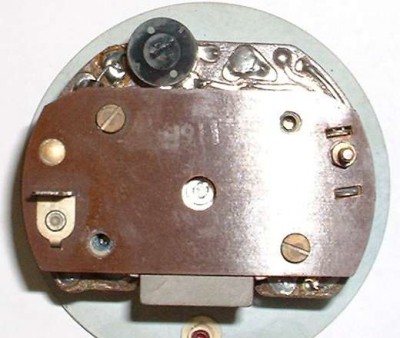

The calibration pot is shown on the last photo. You only need to turn it less than a quarter turn to really move the reading around. If I recall correctly, it feels like you are turning the thing backward when you make the adjustment, sort of like turning it down (clockwise) makes the reading increase. The web site author says the opposite. Easy to figure out as you are doing it.

The hole in the bucket is not strictly speaking required, but a lot safer. I would not recommend connecting the tach and holding it on your hand without the bucket and bezel/glass in place as it is too easy to damage the meter movement. The hole is simply positioned to allow screw driver access to the trimming pot with the bucket in place. You will want to cover the hole after adjustment to prevent dust from getting into the instrument. Avoid touching the gauge face to avoid finger marks; I wore gloves while I had the unit apart at the bench and worked over soft dust free cloth.

After you have removed the bezel and glass, the screws you need to remove to separate the internals from the bucket are shown in the first two photos. There are two of them that need to be unfastened, and they are located at 2 and 8 O'Clock in the photos. They are NOT the ones in the free holes through the bucket; these ones do not need to be loosened, and you can see them still in position with the board attached in the bottom photo. Anyway, the two you need to unfasten are obvious if you know to look for them and leave the other two screws in place.

HTH

This link has some photo's, although it is not the site I was trying to find. Don't worry about a lot of the discussion as it is not relevant to your problem, although the author describes the calibration procedure and has a cool idea to calibrate using a cheap charger. The calibration may be enough to "fool" the tach reading for different engine cylinder count, but I don't believe this is its primary purpose. I understand its primary purpose is to resolve exactly your problem, and to allow adjustment as some of the components age and change values or to take up slop in the precision of the components even when new. Your tach could have been out of calibration all along; I know mine was by about 1000 rpm but I did not realize it. All good now compared to the clip-on, and was able to confirm comparing GPS speed readings and rpm's in fourth gear and calculating rpm's based on diff ratio.

Your tach may be slightly different than the one in the photo's. For the Plus 2 I have two indicator lights in the bottom of the tach housing. This one appears to have only one. Not sure for Europa. In any case, not an issue.

http://mgaguru.com/mgtech/electric/et202c.htm

Here are some of the relevant photos from the above site. I don't think the plastic dingus will really matter all that much in terms of tach calibration, but who knows. Reading the web site again, I see the author points out the plastic piece is in effect part of the loom, so could easily have been missed during your re-wire; I recall I almost missed it on my car until I cut it out of the old loom and threaded it into the new wiring. Still a good idea to make sure the white coil wire cannot possibly wear through and short to ground on the tach bucket, as this will halt all forward progress of the car in a rather dramatic fashion with attendant sparks and smoke.

The calibration pot is shown on the last photo. You only need to turn it less than a quarter turn to really move the reading around. If I recall correctly, it feels like you are turning the thing backward when you make the adjustment, sort of like turning it down (clockwise) makes the reading increase. The web site author says the opposite. Easy to figure out as you are doing it.

The hole in the bucket is not strictly speaking required, but a lot safer. I would not recommend connecting the tach and holding it on your hand without the bucket and bezel/glass in place as it is too easy to damage the meter movement. The hole is simply positioned to allow screw driver access to the trimming pot with the bucket in place. You will want to cover the hole after adjustment to prevent dust from getting into the instrument. Avoid touching the gauge face to avoid finger marks; I wore gloves while I had the unit apart at the bench and worked over soft dust free cloth.

After you have removed the bezel and glass, the screws you need to remove to separate the internals from the bucket are shown in the first two photos. There are two of them that need to be unfastened, and they are located at 2 and 8 O'Clock in the photos. They are NOT the ones in the free holes through the bucket; these ones do not need to be loosened, and you can see them still in position with the board attached in the bottom photo. Anyway, the two you need to unfasten are obvious if you know to look for them and leave the other two screws in place.

HTH

- Attachments

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 2063

- Joined: 03 Sep 2007

17 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 27 guests