Speedo angle drive questions.

33 posts

• Page 2 of 3 • 1, 2, 3

Is this the fiber washer?

"Checked out RDent's Parts Manual for diagram of *washer.

http://www.rdent.com/manuals/index.html

* Parts Manual>Transmission>Casing>Item 40>Part #E316-ME-1>Gasket"

"Checked out RDent's Parts Manual for diagram of *washer.

http://www.rdent.com/manuals/index.html

* Parts Manual>Transmission>Casing>Item 40>Part #E316-ME-1>Gasket"

- bdea

- First Gear

- Posts: 45

- Joined: 23 Oct 2003

bdea wrote:Is this the fiber washer?

"Checked out RDent's Parts Manual for diagram of *washer.

http://www.rdent.com/manuals/index.html

* Parts Manual>Transmission>Casing>Item 40>Part #E316-ME-1>Gasket"

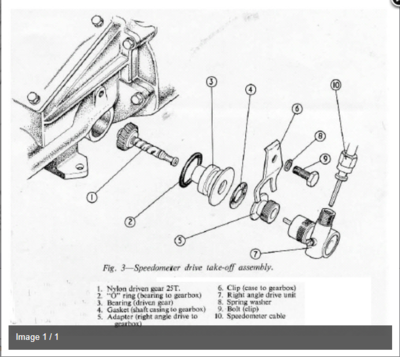

No. That gasket (washer) #40 goes between the Speedo gear housing and the adaptor piece.

As said before, as far as I know, there was never any form of seal between the adaptor and the angle drive itself and certainly it does not appear in the parts list. I have added a washer in there during my various attempts to stop the leaks.

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1969

- Joined: 02 Jan 2008

This is way to go..

lotus-talk-f50/how-your-this-almost-hate-question-t39252.html

lotus-talk-f50/how-your-this-almost-hate-question-t39252.html

-

mark030358 - Coveted Fifth Gear

- Posts: 1182

- Joined: 29 May 2004

Errr, slightly off topic, but my speedo cable has (I think) snapped. I have a Plus 2 with the Lotus five speed box. So I am wondering how I get to that angled drive without taking the engine, gearbox or both out.

Has anyone cut a hole in the top of the transmission tunnel to get to it? I would glass it back in afterwards, or if a circular hole put a big rubber bung, grommet over the hole, just in case I have to do it again. This method does feel wrong!

Any other method gratefully recieved.

Kind regards

Jeff 72+2 5 speed.

Has anyone cut a hole in the top of the transmission tunnel to get to it? I would glass it back in afterwards, or if a circular hole put a big rubber bung, grommet over the hole, just in case I have to do it again. This method does feel wrong!

Any other method gratefully recieved.

Kind regards

Jeff 72+2 5 speed.

-

jeff jackson - Fourth Gear

- Posts: 578

- Joined: 31 May 2004

On the 5 speed the right angle drive is on the upper rear/right of the tail housing behind the gearstick and roughly above the gearbox mount. I'd expect direct access to be shield by the chassis (fold metal chassis anyway) so cutting a hole in the body won't give you access.

I think you might just about be able to get it from the u joint access hole reaching forwards (and upwards). Failing that I'd see if i could lower the gearbox enough to be able to get a hand to it via the gearstick hole. You'll need to remove the center console, gearstick (don't forget to put it in gear first), may be loosen/remove engine mounts and disconnect the gearbox mount plate to the chassis.

I think you might just about be able to get it from the u joint access hole reaching forwards (and upwards). Failing that I'd see if i could lower the gearbox enough to be able to get a hand to it via the gearstick hole. You'll need to remove the center console, gearstick (don't forget to put it in gear first), may be loosen/remove engine mounts and disconnect the gearbox mount plate to the chassis.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2708

- Joined: 07 Jun 2013

Hi All,

Thanks for the replies. Didn't think it would be as easy as that. Iwill try dropping the gearbox down a bit and see if I can get to it. Failing that I will start growing octopus arms.

Regards

Jeff 72+2 5 speed

Thanks for the replies. Didn't think it would be as easy as that. Iwill try dropping the gearbox down a bit and see if I can get to it. Failing that I will start growing octopus arms.

Regards

Jeff 72+2 5 speed

-

jeff jackson - Fourth Gear

- Posts: 578

- Joined: 31 May 2004

Here's a photo I found that shows the box and engineer out of the car. Do you can get a good idea of location.

If cable isn't too tight if think you'd have decent chance via prop shaft access hole.

If cable isn't too tight if think you'd have decent chance via prop shaft access hole.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2708

- Joined: 07 Jun 2013

One of the first jobs I had to tackle on my Elan was the erratic speedo behaviour (it bounced enthusiastically ±20mph road speed). The cable outer was worn and had been made to run a tight radius down by the gearbox so it was ready for replacement. There was also a little oil weeping from the angle drive.

I undid the gearbox mounting brackets and gently lowered the tail of the gearbox using a jack which gives sufficient space to see what you're doing. The angle drive dropped out easily as the clip screw was only finger tight! The whole adapter and drive could easily rotate and there was limited pressure on the bearing o-ring.

The speed angle drive looked in generally good condition, span freely and the quill was barely worn. But the speedo cable had been cross threaded onto the angle drive.

I had the thread chased out by a local machinist. For future reference its a ¾" x 26tpi British Standard Brass (BSB) thread. After regreasing the drive and installing new paper gasket and experimenting with a fibre sealing washer (5/16" ID, 5/8" OD) on the cable end I've not had any subsequent leaks and the speedo is smooth at legal speeds.

I hope that is of some use to people on similar predicaments.

I undid the gearbox mounting brackets and gently lowered the tail of the gearbox using a jack which gives sufficient space to see what you're doing. The angle drive dropped out easily as the clip screw was only finger tight! The whole adapter and drive could easily rotate and there was limited pressure on the bearing o-ring.

The speed angle drive looked in generally good condition, span freely and the quill was barely worn. But the speedo cable had been cross threaded onto the angle drive.

I had the thread chased out by a local machinist. For future reference its a ¾" x 26tpi British Standard Brass (BSB) thread. After regreasing the drive and installing new paper gasket and experimenting with a fibre sealing washer (5/16" ID, 5/8" OD) on the cable end I've not had any subsequent leaks and the speedo is smooth at legal speeds.

I hope that is of some use to people on similar predicaments.

Andy

Elan Coupe 36/5245

Instagram: @sidney_the_elan

https://www.thingiverse.com/andy_makes_spares/designs

- lowflyer

- First Gear

- Posts: 25

- Joined: 17 Aug 2020

Can I ask a silly question? I, too, have a leaking angle drive, but I also notice that there's some weeping from the bearing in which the nylon driven gear inside the tailshaft. Is it possible to pull the bearing (and drive gear?) out of the casing while the gearbox is in place to get at the o-ring? I'm thinking that replacing it, along with a slight bit of sealant between the casing and bearing shoulder should help reduce my current leak tremendously. Also, if this is possible, am I correct in assuming that putting it back together is just a simple reversing of the disassembly process?

Thanks in advance.

Thanks in advance.

- chrisawyer

- New-tral

- Posts: 9

- Joined: 24 Aug 2013

I don't know about the 5 speed gearbox but if you have the 4 speed then it is possible to remove the gear and bearing with the gearbox in place but it is awkward to get to and that can make prising the bearing out of the casing a bit of a challenge, you just need a bit of patience. You will get some oil run out when you remove it, even if the gearbox has been drained first, so be prepared for that. Replacement is just a reversal of the removal procedure but you may want to consider adding an O ring (in addition to the paper gasket) between the bearing housing and the adaptor. There isn't one shown on the parts diagram but the recess in the housing is deep enough and a standard size (BS013) fits perfectly.

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1969

- Joined: 02 Jan 2008

Yes you remove the fork that holds the aluminium bearing in place and just lever out the bearing and the plastic gear. There is an O-ring on the bearing that can be replaced to seal it properly or you can put some sealant under the flange as you indicated.

Make sure the fork has not distorted and that it is firmly holding the bearing in place.

Assembly is just reverse of removal.

The gear shaft through the bearing has no seal and just a grooved scroll along it to hopefully move the oil back up the shaft and into the gearbox. Its is normally leaks along this that are the problem. Trying to seal the angle drive better helps but difficult to get total oil tight !

I have thought about machining the bearing to fit a small lip seal but never got around to it. Just one of many improvement opportunities

cheers

Rohan

Make sure the fork has not distorted and that it is firmly holding the bearing in place.

Assembly is just reverse of removal.

The gear shaft through the bearing has no seal and just a grooved scroll along it to hopefully move the oil back up the shaft and into the gearbox. Its is normally leaks along this that are the problem. Trying to seal the angle drive better helps but difficult to get total oil tight !

I have thought about machining the bearing to fit a small lip seal but never got around to it. Just one of many improvement opportunities

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8831

- Joined: 22 Sep 2003

In addition to Rohan and Roger's comments, you can get access by lowering the tail of the gearbox. Just support the gearbox with a jack and lower once the chassis mounting bolts are removed.

Andy

Elan Coupe 36/5245

Instagram: @sidney_the_elan

https://www.thingiverse.com/andy_makes_spares/designs

- lowflyer

- First Gear

- Posts: 25

- Joined: 17 Aug 2020

A tip somewhere in this forum that originated (apparently) from Dave Bean is to give up trying to seal the adapter and bearing with the paper/fibre gasket and simply glue the two pieces together.

Once you fiddle with the cursed thing enough you realize that the adapter is just that, an adapter. It serves no other purpose and can be considered a single piece with the bearing. The two pieces can be glued together with an aluminium epoxy and fix the leak at that joint once and for all.

Initially I wasn't too keen on this idea but then decided that it was trivial and harmless. The resulting single piece is simpler to fit/remove than the two separate pieces. Of course, my angle drive still leaks everywhere else but one day I'll master it.....

Nick

Once you fiddle with the cursed thing enough you realize that the adapter is just that, an adapter. It serves no other purpose and can be considered a single piece with the bearing. The two pieces can be glued together with an aluminium epoxy and fix the leak at that joint once and for all.

Initially I wasn't too keen on this idea but then decided that it was trivial and harmless. The resulting single piece is simpler to fit/remove than the two separate pieces. Of course, my angle drive still leaks everywhere else but one day I'll master it.....

Nick

-

elanner - Fourth Gear

- Posts: 615

- Joined: 14 Sep 2010

33 posts

• Page 2 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 17 guests