Differential:- Pinion replacement & bearing pre-loading

13 posts

• Page 1 of 1

Another Differential question I?m afraid ! I?ve read through many posts on this and other sites but still a bit unclear on some aspects of this jigger-pokery.

I am fitting the correct pinion flange to a differential that was fully rebuilt some while ago but never used. This was built with an incorrect flange.

It does not currently have a flange fitted, so I can?t mark the position (and it is a different flange anyhow), I am also be unsure about the condition of the crush spacer, so am making the assumption it is not useful.

The diff is currently on my bench with the rear casing & output shafts attached. I have a new pinion seal, collapsible spacer, the flange and the special nut.

Can I set up the pinion bearing pre-load with the diff as it is currently, or do the shafts & casing have to come off ?

eg will the diff come apart enough to fit the crush spacer once the seal is removed ?

does the meshing / backlash etc need checking again, or will this remain correct if the pre-load is done ?

I have seen methods described that involve a spring balance hooked to the flange (prop fitting holes). Will the numbers be correct with the rest of the diff/output shafts fitted , or are they not really involved in this setting ?

If this method is suitable, what should I be aiming for on the spring balance ? [I don?t have a dial torque wrench and they look pretty pricey. Once I have acquired one, I can calibrate a spring balance easily enough]

Another alternative I have heard of is to use a bottle of water in place of the spring balance (again, I can calibrate this on a decent balance) and tighten up until the water bottle won?t drag the flange around anymore.

I would probably calibrate for the upper, lower and mid points. Then setup the diff for something below the lower setting as a trial, then for the lower value , then the mid value and do a check against the upper value. Should this work ?

Regards

Adrian

I am fitting the correct pinion flange to a differential that was fully rebuilt some while ago but never used. This was built with an incorrect flange.

It does not currently have a flange fitted, so I can?t mark the position (and it is a different flange anyhow), I am also be unsure about the condition of the crush spacer, so am making the assumption it is not useful.

The diff is currently on my bench with the rear casing & output shafts attached. I have a new pinion seal, collapsible spacer, the flange and the special nut.

Can I set up the pinion bearing pre-load with the diff as it is currently, or do the shafts & casing have to come off ?

eg will the diff come apart enough to fit the crush spacer once the seal is removed ?

does the meshing / backlash etc need checking again, or will this remain correct if the pre-load is done ?

I have seen methods described that involve a spring balance hooked to the flange (prop fitting holes). Will the numbers be correct with the rest of the diff/output shafts fitted , or are they not really involved in this setting ?

If this method is suitable, what should I be aiming for on the spring balance ? [I don?t have a dial torque wrench and they look pretty pricey. Once I have acquired one, I can calibrate a spring balance easily enough]

Another alternative I have heard of is to use a bottle of water in place of the spring balance (again, I can calibrate this on a decent balance) and tighten up until the water bottle won?t drag the flange around anymore.

I would probably calibrate for the upper, lower and mid points. Then setup the diff for something below the lower setting as a trial, then for the lower value , then the mid value and do a check against the upper value. Should this work ?

Regards

Adrian

1968 Elan plus 2 - project

2007 Elise S2 [modified with a Hethel 70th sticker (yellow)]

2000 Elise S1 - Sold

2007 Elise S2 [modified with a Hethel 70th sticker (yellow)]

2000 Elise S1 - Sold

- wotsisname

- Third Gear

- Posts: 452

- Joined: 24 Jun 2015

Adrian,

I had to face this recently after fitting new bearings and output shafts to a spare diff and realising at the point of fitting to the car that the flange had the wrong pcd.

Not what you probably want to hear but I just swapped them over, retained the crush tube, and re torqued to Lotus spec.

It 'felt' right when I did this (by turning the flange by hand) and after 2000 miles it's quiet as a mouse and gives no trouble at all.

I had to face this recently after fitting new bearings and output shafts to a spare diff and realising at the point of fitting to the car that the flange had the wrong pcd.

Not what you probably want to hear but I just swapped them over, retained the crush tube, and re torqued to Lotus spec.

It 'felt' right when I did this (by turning the flange by hand) and after 2000 miles it's quiet as a mouse and gives no trouble at all.

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

There is no tightening torque specification for the pinion flange nut. The torque on the nut is determined by the point at which the crush tube starts to crush which may vary somewhat from crush tube to crush tube. You would be leaving it to luck only if you just swapped the flanges over relying on "feel".

Although it may be possible to set the pinion preload with the axle shafts still attached I would prefer not to do it that way. The drag of the axle shafts, axle shaft bearings, brakes etc. would mean the pinion preload contribution to the measured torque would be reduced and hence the ultimate accuracy of the setting would be reduced.

Far better to set it with the axle shafts removed or the carrier out of the housing. BEFORE removing the original pinion flange you need to measure what the current pinion running torque is. Best to use a spring balance for this. You don't need to worry too much about calibrating it. We aren't concerned about absolutes figures here - we are only interested in getting the running torque of the pinion with the new flange the same as it was with the old flange. We are of course assuming that the pinion with the old flange was set up correctly originally.

Be sure to use a new crush tube (available from Burtons). Preferably a new pinion nut (note - there's early and late type nuts. The early thinner type depends on staking for locking the later type is a much thicker locking nut and much more secure. You can use the later nut on early differentials no problem). Don't use a new pinion seal as it will affect the preload measurement. You shouldn't have to if the differential is a reconditioned unit anyway.

With the new pinion and crush tube fitted just set the pinion running torque to the same figure it was before. Beware though that when the crush tube starts to crush and the end float of the pinion is zero the pinion running torque will increase rapidly for even very small tightenings of the pinion nut so you need to be careful. If you go past the setting you will need to repeat the process with a new crush tube.

You don't need to worry about pinion backlash, depth of mesh etc. If you set the pinion running torque to what it was originally these should not have changed.

Although it may be possible to set the pinion preload with the axle shafts still attached I would prefer not to do it that way. The drag of the axle shafts, axle shaft bearings, brakes etc. would mean the pinion preload contribution to the measured torque would be reduced and hence the ultimate accuracy of the setting would be reduced.

Far better to set it with the axle shafts removed or the carrier out of the housing. BEFORE removing the original pinion flange you need to measure what the current pinion running torque is. Best to use a spring balance for this. You don't need to worry too much about calibrating it. We aren't concerned about absolutes figures here - we are only interested in getting the running torque of the pinion with the new flange the same as it was with the old flange. We are of course assuming that the pinion with the old flange was set up correctly originally.

Be sure to use a new crush tube (available from Burtons). Preferably a new pinion nut (note - there's early and late type nuts. The early thinner type depends on staking for locking the later type is a much thicker locking nut and much more secure. You can use the later nut on early differentials no problem). Don't use a new pinion seal as it will affect the preload measurement. You shouldn't have to if the differential is a reconditioned unit anyway.

With the new pinion and crush tube fitted just set the pinion running torque to the same figure it was before. Beware though that when the crush tube starts to crush and the end float of the pinion is zero the pinion running torque will increase rapidly for even very small tightenings of the pinion nut so you need to be careful. If you go past the setting you will need to repeat the process with a new crush tube.

You don't need to worry about pinion backlash, depth of mesh etc. If you set the pinion running torque to what it was originally these should not have changed.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2165

- Joined: 10 Jun 2015

On re-reading this apparently you don't currently have a pinion flange fitted and so therefore you won't have a baseline pinion running torque figure to work with. In that case you will have to set it to the correct value using a spring balance and the figures given in the workshop manual taking into account whether you are using new or used pinion bearings and new or used pinion seal. You will need to use some maths though to work it out and also to calculate the torque for any given reading on the spring balance. Torque = force x distance.

Also you shouldn't attempt to measure it with the axle shafts connected if this is the case. The workshop manual figures are for the differential centre out of the car and on the work bench.

Also you shouldn't attempt to measure it with the axle shafts connected if this is the case. The workshop manual figures are for the differential centre out of the car and on the work bench.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2165

- Joined: 10 Jun 2015

Thank you, both, for your replies. 2cams70, you have pretty much confirmed my suspicion that I need to pull the shafts. I guess this means a slide hammer [I will attempt to make one], unless anyone has a viable alternative... The drive shaft bearings & circlips are "new" (although fitted for some while] , is there a recommended "glue" for re-fitting of the bearing into the housing.

I'll take this opportunity to count the teeth (it's a 3.5?) and replace the gasket, etc

Adrian

I'll take this opportunity to count the teeth (it's a 3.5?) and replace the gasket, etc

Adrian

1968 Elan plus 2 - project

2007 Elise S2 [modified with a Hethel 70th sticker (yellow)]

2000 Elise S1 - Sold

2007 Elise S2 [modified with a Hethel 70th sticker (yellow)]

2000 Elise S1 - Sold

- wotsisname

- Third Gear

- Posts: 452

- Joined: 24 Jun 2015

..I used the loctite 603(?) metal repair for the output bearings which according to the blurb will take up to 0.5mm wear on shafts. It's silver in colour and worked well for me - the previous diff had spun an output shaft bearing even though the housing was not apparently worn so i will use from now on.

Point take on the pinion nut, if you've no original reference point and have fitted new taper bearings (had not realised that). There is a pinion nut torque value in the Lotus manual however and I torqued mine up to that, did the 'feel' test and it worked for me but that was on a simple flange changover with nothing else altered.

Jon

Point take on the pinion nut, if you've no original reference point and have fitted new taper bearings (had not realised that). There is a pinion nut torque value in the Lotus manual however and I torqued mine up to that, did the 'feel' test and it worked for me but that was on a simple flange changover with nothing else altered.

Jon

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

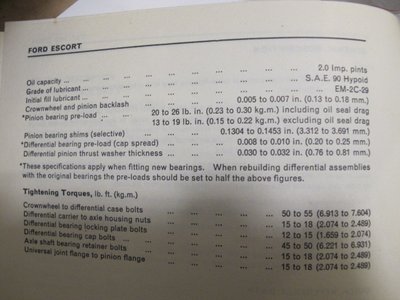

I've attached an extract from the Ford manual for the preload setting. I'm surprised the Lotus manual lists a torque value for the pinion nut. It's not in the Ford manual. Normally a torque figure is only stated for differentials that use a solid spacer and shims to set the pinion preload. I believe some people do replace the original collapsible spacer with a solid spacer and shims but I've certainly never found it necessary to do so. For differentials using a solid type spacer the pinion nut torque figure is usually very high. I did one of these once and I had to borrow a long arm truck torque wrench from work to tighten the nut. My normal 120ft/lb one wasn't enough! To loosen it I kept the car on it's wheels and used a hydraulic jack acting on the end of a socket handle.

Also I use this slide hammer tool made from a scrap Ford Escort half shaft to remove axles. Nothing gets in it's way. Guaranteed removal no matter how rusted in the bearing is! I'm not sure what the wheel nut PCD is on a Lotus but you may be able make up something similar.

Also I use this slide hammer tool made from a scrap Ford Escort half shaft to remove axles. Nothing gets in it's way. Guaranteed removal no matter how rusted in the bearing is! I'm not sure what the wheel nut PCD is on a Lotus but you may be able make up something similar.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2165

- Joined: 10 Jun 2015

Contact Al..... "promotor" on this site .....he'll sort you out, dont waste your time doing a half hearted job unless you want to do the job again.........

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3407

- Joined: 11 Sep 2003

If you do set the crush tube up on running torque it is worth knowing that the diameter of the pinion shaft just behind the flange is 2 inches, i.e. 1 inch radius, so hanging a 10 lb weight on a string wound around it gives you the correct value of 10 lb-in. A UK gallon of water weighs 10 lb but is much larger and less stable than a lump of metal in a bag.

You have to find a way of locking the flange while you tighten the nut and test the running after each increment of tightening. I found I needed over 100 lb-ft torque to crush the tube.

You have to find a way of locking the flange while you tighten the nut and test the running after each increment of tightening. I found I needed over 100 lb-ft torque to crush the tube.

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1170

- Joined: 03 Oct 2012

One other thing to consider also is that if you are measuring the pinion torque with the crown wheel carrier fitted you will also be including the torque caused by the preload on the differential carrier side bearings - i.e it won't be just the pinion bearing torque you are measuring. I don't have the manual in front of me at the moment but if I recall correctly the torque figure given in the manual is for the pinion bearings only not including the carrier bearings. If that's the case things are a little more complicated and you may be better off getting a professional to do it. Or you can try backing off one of the carrier bearing adjuster rings to relieve the preload whilst attending to the pinion bearings, move it back to the original position when finished and hope it's setting hasn't changed.

For adjusting the carrier bearings I use one of these tools. Works great.

http://www.ebay.com.au/itm/ENGLISH-AXLE ... SwL7VWo31F

It complicates things now that the original flange has already been removed since there is no baseline figure to work with.

For adjusting the carrier bearings I use one of these tools. Works great.

http://www.ebay.com.au/itm/ENGLISH-AXLE ... SwL7VWo31F

It complicates things now that the original flange has already been removed since there is no baseline figure to work with.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2165

- Joined: 10 Jun 2015

I don't think the drag of the crownwheel assembly or the output bearings (with or without output shafts) is a problem when setting the pinion preload as the drag is reduced by the large diameter of the crown wheel compared to its bearings and the differential ratio. I don't recall it being noticeable when I did it in 2012 but it could be measured at the pinion, before it starts getting tight, and added to the preload target.

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1170

- Joined: 03 Oct 2012

Adrian,

In your original post you say:

"I am fitting the correct pinion flange to a differential that was fully rebuilt some while ago but never used. This was built with an incorrect flange."

If you are confident the rebuild was good except for the incorrect flange, just change the flange (and seal as easy). Recall the crush spacer is to prevent the bearing races from binding if over tightened and also to not be too loose, it really has nothing to do with the flange depth.

The advice of others is great: you could check that with the new flange tightened up (but not over tightened) the bearings are free and also pull axially on the flange to see if excessive end float (which would mean the crush washer still needs to be crushed). As said by others it takes a lot of torque to crush the spacer, (I noticed the new one was a lot thicker material than an old one that came out).

Jack

In your original post you say:

"I am fitting the correct pinion flange to a differential that was fully rebuilt some while ago but never used. This was built with an incorrect flange."

If you are confident the rebuild was good except for the incorrect flange, just change the flange (and seal as easy). Recall the crush spacer is to prevent the bearing races from binding if over tightened and also to not be too loose, it really has nothing to do with the flange depth.

The advice of others is great: you could check that with the new flange tightened up (but not over tightened) the bearings are free and also pull axially on the flange to see if excessive end float (which would mean the crush washer still needs to be crushed). As said by others it takes a lot of torque to crush the spacer, (I noticed the new one was a lot thicker material than an old one that came out).

Jack

- jk952

- Third Gear

- Posts: 258

- Joined: 04 Jan 2011

Meg's suggestion is great. Measure the torque with no preload on the pinion bearings. That will give you the torque figure for the carrier bearings. The final figure you need to aim for is then the carrier bearing torque + the pinion bearing torque.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2165

- Joined: 10 Jun 2015

13 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 23 guests