Page 1 of 1

grinds going into 2nd and third

Posted:

Mon Jul 28, 2014 1:38 pmby mini64

Anyone have a suggestion for a next step for me to look at. For some time now I've had the racer grind, or feel like it is bumping teeth, when I shift up or down to second. Just a quick crunch. This happened in the "old" box, and now since I've put all new straight cut internals in it, it still grinds. So the gears are new, the synchros are new. Should I be looking at the "teeth" in the ID of the selector fork rings (I forget what they are called, the part the selector fork moves to lock the gear to the shaft), the little keys in there, or something else? I swear it has started doing it a bit going into third now which is of course a different set.

Re: grinds going into 2nd and third

Posted:

Mon Jul 28, 2014 9:29 pmby europatek

Most likely cause is the synchro hub and/or the blocker bars. I've rebuilt several gearboxes and never had to replace a synchro ring only the hub and blockers.

Re: grinds going into 2nd and third

Posted:

Mon Jul 28, 2014 9:36 pmby ricarbo

I think the grating noise is from the small teeth on the synchro rings hitting the corresponding grooves in the part you call the 'selector fork ring'. i believe it is called the sliding sleeve. It is because the synchro action isn't working properly to bring the two parts to the same speed. If you take the synchros to bits, you should find the conical face of the ring grabs the cone on the gear under even quite light finger pressure. When my gearbox was doing this, even with new synchro rings, it was found the cones on the gears were ridged and worn. They had to be machined on a lathe to restore the gear cones to the correct finish. Surprising that you are getting this with all new parts, but that's where I would be looking. I wouldn't describe myself as an expert.

regards

Richard

Re: grinds going into 2nd and third

Posted:

Wed Jul 30, 2014 4:36 pmby mini64

Europatek,

How did you inspect the blocker bars and synchro hub? Looking for visual damage or are there wear tolerances that can be measured? I've never replaced the blocker bars - wonder if they could be the problem.

Re: grinds going into 2nd and third

Posted:

Fri Aug 01, 2014 2:08 amby europatek

You can visually inspect the bump on the blocker bars comparing it to others or a new one as well as feeling the assembled hub. Move it back and forth noting the amount of detent/resistance as the hub passes over the bumps in the blockers. Sometimes if the blockers are worn the hub moves back and forth with little resistance from the blockers. New or good blockers produce a definative resistance and "click" over the blockers with intent. I think I've explained that properly..

Re: grinds going into 2nd and third

Posted:

Fri Aug 01, 2014 2:24 amby rgh0

Also have a close look at the synchro ring for wear on the grooved face that matches the gear hub. There should be a clearance between the synchro ring and the shoulder on the gear hub and the ring should grip the hub before it reaches the shoulder. There is a specified clearance for this gap but I cannot locate it currently.

cheers

Rohan

Re: grinds going into 2nd and third

Posted:

Fri Aug 01, 2014 10:33 amby oldchieft

Been a long time since I worked on car gear boxes, but if i recall correctly the three springs and balls in the hub are what control the force pressing the bulk ring on to the cone face of the gear.

If the springs were not changed then that could be why you had a crunch in it before and you still have it with new parts.

Jon the Chief

Re: grinds going into 2nd and third

Posted:

Mon Aug 04, 2014 3:15 amby mini64

You guys are on to something - thank you. On both 1st and second I can push the synchro ring right up against the gear hub shoulder. Strange as these synchro rings only have a partial race weekend on them. I'm beginning to wonder if I have late/early types mixed up.

I've never replaced the 1-2 springs or blocker bars so I'll do that also.

Re: grinds going into 2nd and third

Posted:

Wed Aug 06, 2014 3:24 pmby joe7

Ran into the same problem with aftermarket 1/2 syncro rings but luckily before assembling the trans. The rings bottomed out on the gear shoulder in both 1st and 2nd. Installed a slightly used set of rings, checking clearance before assembly. 1st gear clearance @ .066 & 2nd @ .062. I usually like to see around .040 to .050 minimum clearance on 1st & 2nd gear, the more the better. NOS rings I have get about .070+. Or could be 2 worn gear hubs? For some reason the clearance seems to be smaller for 3rd & 4th (input shaft) @ .045 to 050. Also you may want to check your end float on 1st, 2nd & 3rd after assembly.

two findings

Posted:

Sat Sep 20, 2014 10:04 pmby mini64

first, my third gear synchro ring was broken at one of the bar locations AND the other two are cracking, ready to break

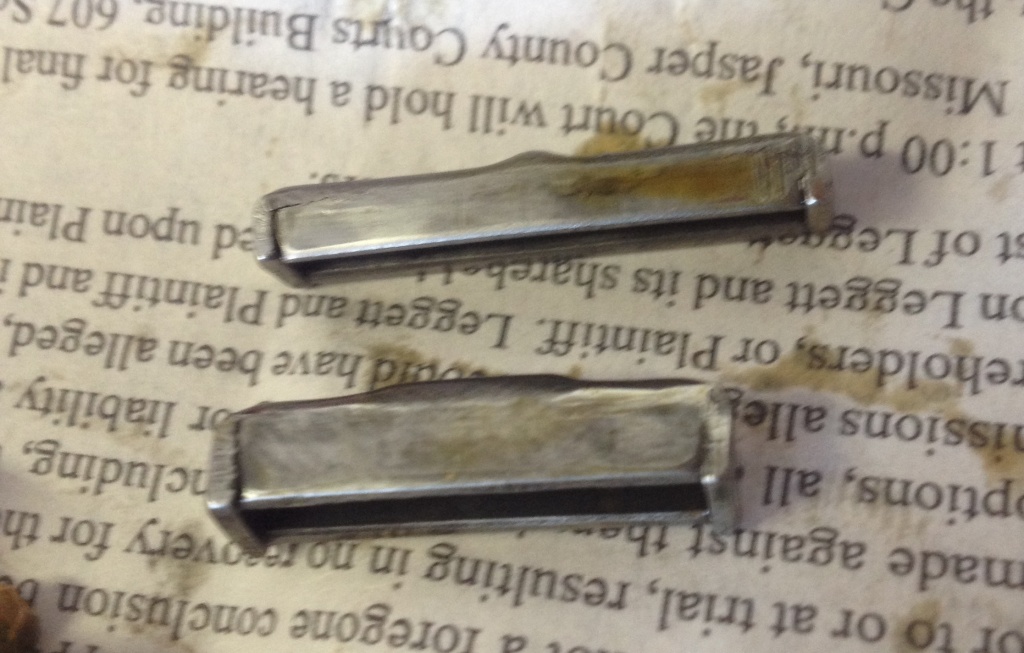

am I using the wrong blocker bars? here they are below. the new ones I bought from burton; they are solid rather then pressed like this, but their overall thickness at the ends is the same. they say for the late box.

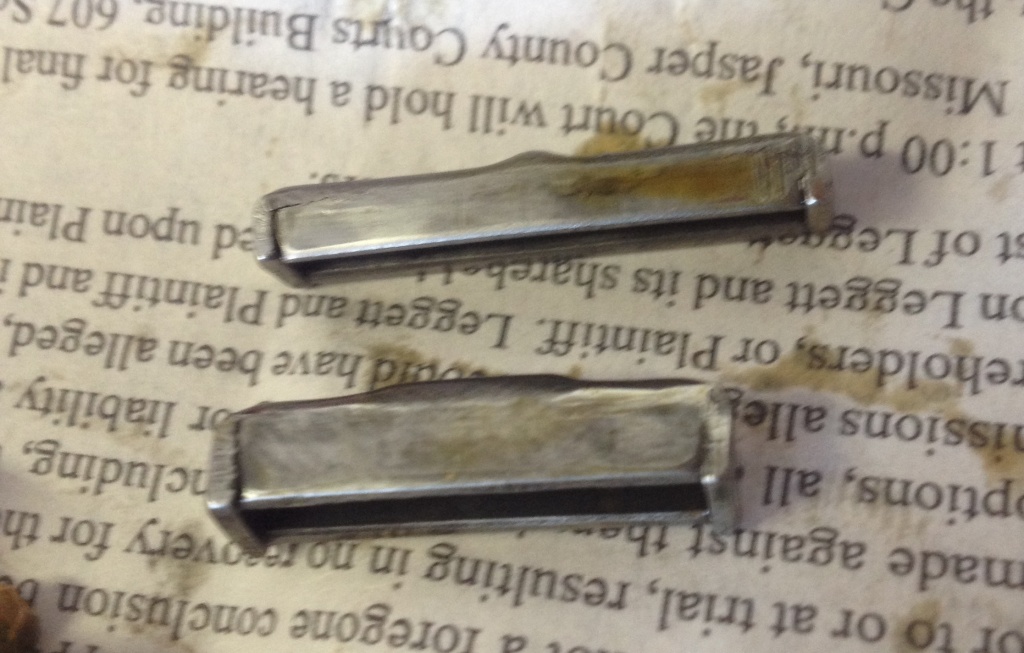

and then, within the hubs, I find there is a raised lip just past the pointed bit. see the red arrows in the below pic:

is this bad? can they be filed off?

any thoughts?

Re: grinds going into 2nd and third

Posted:

Sat Sep 20, 2014 11:52 pmby Craven

Hi.

Looks to me as if you have a late type syncro ring with an earlier hub, if you look at the indent inside hub it is quite small, the block bar hump should be a corresponding size, as top bar in photo, BUT your syncro ring uses the lower block bar, so you need the early type syncro ring, they have engaging teeth all the way round.

This is from memory you need confirmation of this.

May help

Ron.

Re: grinds going into 2nd and third

Posted:

Sun Sep 21, 2014 11:13 amby Craven

Hi,

These three pieces go together, Hub large indent, short block bar with long bump, syncro ring 3 groups of 6 teeth and is much thicker construction than early type hence short block bars.

This is the late type gearbox set up, good guide is the mainshaft speedo drive is plastic and held in place by a circlip ( no large nut ).

Ron.

Re: grinds going into 2nd and third

Posted:

Sun Sep 21, 2014 9:52 pmby mini64

Ron, Thanks for the reply. Now I'm even more confused as I would have called the synchro rings you show the early type in that the notch for the bars goes all the way through them. The post below is where I am getting this:

lotus-suspension-f42/synchro-hub-alignment-t23895.htmlMy rings are all supposedly the late type and the notches do not go all the way through.

Nevertheless, the large hump on the back of the bar would logically go in a hub with a large indent as you say. Both my hubs have small recesses/indents. My 3/4 is supposed to be all late style as I bought it as a kit from Bean- hub, ring, synchros, bars, springs. But Bean often miss packages things so I don't consider this the gospel.

Worse yet, I bought new bars from burton as Bean didn't seem to have any. I ordered the late ones on the following link for both 1/2 and 3/4, but what they sent me, packaged in the part numbers the page shows, has the small hump long bars for 1/2 and long hump short bars for 3/4?!

http://www.burtonpower.com/parts-by-fit ... l?limit=40Can someone throw in another opinion please?

Re: grinds going into 2nd and third

Posted:

Sun Sep 21, 2014 11:49 pmby Craven

Hi,

Like many long running production parts improvements take place, my picture is of a late type syncro ring but a slightly different version, I believe the three groups of teeth identify this type.

Early block bars, shown in pic have extended ends, that positively locate the spring, and both have small hump on the back.

Pic of the 2 syncro rings show a late type, as yours, but the other a much lighter construction with teeth all the way round and is an early ring. I think your hub is early and should have block bars with small hump and extended ends and the lighter syncro ring with teeth all the way round.

Unfortunately I can?t put my hands on a late rear hub to check the block bar size but it is quite possible that the long bars supplied by Burtons are correct and can be used with your rear hub and rings.

Ron.