Quaiffe Helical Gear set for 4 speed

41 posts

• Page 2 of 3 • 1, 2, 3

rgh0 wrote:Yes modern GL5 oils contain less sulphur based anti wear additives to achieve the GL5 rating for sliding tooth contact so they are less corrosive for brass components.

The real question is why GL5 at all as the gear box is a helical gear set with only rolling tooth contact it should have no sliding tooth contact like a hypoid diff does which is what GL5 oils are intended for.

The other question is why a 140 weight oil compare to the lighter oils orginally used in this gear box. There may be minor differences in gear geometry but the loads and pitch circles and gear tooth contact faces are pretty much fixed by the dimensions of the box and the gear ratios so what is creating the need for such a signficant change. The heavier weight oil will also not help the syncro performance especially when cold

Maybe you can asked the "boffins at Quaiffe" that and see if you can get a sensible engineering based answer.

cheers

Rohan

I find the best trade off is not always easy to define : from what I've read AW (Anti Wear) additive used to be lead based, and has been replaced by phosphorus based additive in the 1990s. A sulphur based EP (for Extreme Pressure) additive has been developped so that a layer is bonded to the metal and prevents metal to metal contact by forming a sacrificial layer. Problem occurs when it bonds very strongly to yellow metal, so that a layer of that yellow metal can be peeled off as well (occurs at high temperature and pression).

To prevent that other additives have been developped, "buffuring" the sulfur so that it would not be corrosive to yellow metal, and I understand this is why manufacturers claim modern GL5 oils are not damaging brass synchros.

I've also read that GL4 would contain about half the amount of sulphur additive with respect to GL5 in average, so it's not a black or white situation.

There are also other additives (anti-foam, anti-rust etc)

(nb: film based EP additives using sulphur are not the only option, there is also the dispersion based approach, when molecules are in suspension and would end caught between the surfaces in contact without bonding e.g. Redline Shockproof series).

Ideally one would like the lower viscosity possible for reaching all areas, and at the same time that the film would stay and endure pression and shear when necessary.

Also, slipperiness has to be just right for proper synchromesh operation (friction modifiers FM can be added to play on that parameter, esp. for tuning clutch based LSD).

Yet in some cases (vintage racing) gearboxes are still exposed to harsh condition : I have in mind the Jaguar gearbox of a friend's E-type, that has a tendency to fail from the needle bearing between the input shaft and the output shaft... I would think that the main load there would be pressure, but obviously some shear has taken place eventually, to the point that the film was broken resulting in a time consuming gearbox out maintenance.

I know some of his fellows E-type racers mix oils (GL4 and GL5) in hope to get a better compromise (or is it superstition?), the price of synchros being a fraction of that of the gearset and synchros are not the weakest link apparently anyway (though most have a Moss gearbox, not the Jaguar 4 synchro gearbox, I'm not sure if the weaknesses are identical)... in any case gearbox lubrication is not a simple question (there are some discussions on lubricant topics, e.g. https://www.bobistheoilguy.com/forums/u ... cant_Rheol but it's still not obvious to solve the problem).

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

I don't believe there is a problem. Quaiffe have specified a particular type and brand of oil to use with their gearset. Has anyone experienced any issues when using the recommended oil?? If not I don't think we have a problem. There are sometimes problems caused more by inherent design than the type of oil used - the Moss gearbox in the Jaguar probably falls into that category!

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2164

- Joined: 10 Jun 2015

Can someone explain the extra breather mentioned above?

I'm about to fit the gearbox and motor and dont want to miss the opportunity to improve the breather if it's warranted.

Thank you!

-Kyle

I'm about to fit the gearbox and motor and dont want to miss the opportunity to improve the breather if it's warranted.

Thank you!

-Kyle

'70 S4 Elan - Cosworth BDP & Spyder Chassis

'62 S2 Super Seven Cosworth

'62 S2 Super Seven Cosworth

- disquek

- Second Gear

- Posts: 151

- Joined: 25 Oct 2018

disquek wrote:Can someone explain the extra breather mentioned above?

I'm about to fit the gearbox and motor and dont want to miss the opportunity to improve the breather if it's warranted.

Thank you!

-Kyle

I believe one properly operating breather (e.g. not plugged etc.) is just fine, unlike the engine crancase, the gearbox is not exposed to blow-by or water/coolant ingress that would evaporate under heating from operation...

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

I just noticed that my breather bolt is in the lower right corner. Not the lower left as it should be. I will move it.

Any thoughts on if this could have contributed to leaking?

-Kyle

Any thoughts on if this could have contributed to leaking?

-Kyle

'70 S4 Elan - Cosworth BDP & Spyder Chassis

'62 S2 Super Seven Cosworth

'62 S2 Super Seven Cosworth

- disquek

- Second Gear

- Posts: 151

- Joined: 25 Oct 2018

I might be a little late coming in on this. The gearbox in my S2 which is the EX Murray Brydon Aussie race car, but now a road car, is fitted with the ultra close ratio helical gear set, first gear is really tall, with second, third, fourth, closely stacked.

The box still runs the same original gear set, and I often wondered, if they ever required replacing where I could acquire another set of helical gears, as there's no way I would use noisy straight cut gears in a road car.

I rebuilt this box way back in the early 80s, new bearings, layshaft, needle rollers, etc, etc. I have only ever used 90 gear oil, same as what I use in the diff, with the addition of Nulon Smooth Shift Manual Gearbox and Diff Treatment (G70). Seems to work very well, changed every couple of years, but car would be lucky to cover 3000miles per year.

Racing of course is so much harder on mechanicals, so you want the best of the best lubricants.

The box still runs the same original gear set, and I often wondered, if they ever required replacing where I could acquire another set of helical gears, as there's no way I would use noisy straight cut gears in a road car.

I rebuilt this box way back in the early 80s, new bearings, layshaft, needle rollers, etc, etc. I have only ever used 90 gear oil, same as what I use in the diff, with the addition of Nulon Smooth Shift Manual Gearbox and Diff Treatment (G70). Seems to work very well, changed every couple of years, but car would be lucky to cover 3000miles per year.

Racing of course is so much harder on mechanicals, so you want the best of the best lubricants.

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

Does anyone know if this gearset is as quiet as the original?

Reason I ask is I'm running the MKF close ratio 'bullet' gearset which works very well but it's quite noisy and becoming a bit tiresome for a road car - turns out it's actually classed as a 'semi helical'

Reason I ask is I'm running the MKF close ratio 'bullet' gearset which works very well but it's quite noisy and becoming a bit tiresome for a road car - turns out it's actually classed as a 'semi helical'

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

My recollection of the original Bullet box is, no increase in noise level over the standard 2000e ratio?s.

However they do suffer from gear frailer if pushed too hard, I?m still looking for a laygear if anyone has a good one to sale, your price paid.

However they do suffer from gear frailer if pushed too hard, I?m still looking for a laygear if anyone has a good one to sale, your price paid.

- Craven

- Coveted Fifth Gear

- Posts: 1624

- Joined: 14 Sep 2013

Jon is referring to the MKF semi helical close ratio set not the original close ratio set. We both have them and they have the same noise as a modern needle roller straight cut box. Hence the question about the new TTR set. Has anybody spun one up to know.

The MKF was described as Sporty Noise.

Mike

The MKF was described as Sporty Noise.

Mike

Mike

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

-

miked - Coveted Fifth Gear

- Posts: 1192

- Joined: 29 Sep 2003

helical , semi helical , straight cut ?????

That's the marketing guys at work again.

The angle of the teeth helix and how many rows of teeth in contact at any one time is what makes it quiet. A larger angle means thinner and more fragile teeth but more in contact at any one time and less noise. The noise comes from teeth engaging and disengaging. if you always have multiple teeth engaged with a higher helix angle then less noise. A straight cut gear has one tooth disengage just as the next engages hence the greater noise.

I guess semi helical means a low helical angle on the teeth hence more noise but higher gear tooth strength. The question is how does it work in practice . Never heard an MKF box in real life and never will now I guess given the sudden demise of that company. Hopefully i will try the Quaiffe one soon

cheers

Rohan

That's the marketing guys at work again.

The angle of the teeth helix and how many rows of teeth in contact at any one time is what makes it quiet. A larger angle means thinner and more fragile teeth but more in contact at any one time and less noise. The noise comes from teeth engaging and disengaging. if you always have multiple teeth engaged with a higher helix angle then less noise. A straight cut gear has one tooth disengage just as the next engages hence the greater noise.

I guess semi helical means a low helical angle on the teeth hence more noise but higher gear tooth strength. The question is how does it work in practice . Never heard an MKF box in real life and never will now I guess given the sudden demise of that company. Hopefully i will try the Quaiffe one soon

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

I was googling around for "helical gear noise" and found a paper I cannot now find that basically said the noise is due to three things, if I remember right:

1 assembly error

2 manufacturing error

3 something that I think was a cyclicality in the longitudinal thrust.

3 was interesting as radial thrust could be constant but the tooth slope made for non-linear behavior along the shaft.

This noise is in addition to the change in tooth angle.

John

1 assembly error

2 manufacturing error

3 something that I think was a cyclicality in the longitudinal thrust.

3 was interesting as radial thrust could be constant but the tooth slope made for non-linear behavior along the shaft.

This noise is in addition to the change in tooth angle.

John

- baileyman

- Third Gear

- Posts: 347

- Joined: 17 Aug 2017

I think MKF was marketing the 3J NXG gear kit, Burton?s ref 3JGK1L. ?1400.

When I see ?Original? quoted I believe this to mean Original Equipment, the close ratio option available with early Elan?s was coined by many as the ? Bullet ? box, 2.5 1st gear helical gear set.

When I see ?Original? quoted I believe this to mean Original Equipment, the close ratio option available with early Elan?s was coined by many as the ? Bullet ? box, 2.5 1st gear helical gear set.

- Craven

- Coveted Fifth Gear

- Posts: 1624

- Joined: 14 Sep 2013

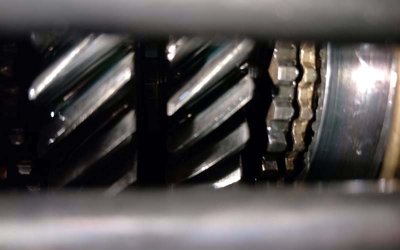

While I am in the process of rebuilding my twin cam engine, the gear box is just sitting there, so I thought that it might be of help to someone if I took the cover off the box and took a shot of the internal helical gears, this is the bullet box, very tall first gear, close ratio gears... this gear box is a delight on the road, or up in the aussie alps in the summer, I run a 3.55 diff ratio, and while it does make first gear very tall and takes a bit of gentle clutch feathering to get it off the line, to me it is the perfect elan gear box.

And runs very quiet.

Shot is taken between the shifter rails, and the angle of the gear teeth are quite evident, If I ever required replacements, I would certainly look to the same gear design.

I don't know the early history of the gear box, whether it was built from parts obtained from the UK, (This would have been in the 1970s) Or if the likes of local Aussie gearbox manufacturer's, Peter Holinger or perhaps others machined/supplied the bits.

There are several engineering places around who would be capable of the CNC machining process, but at what cost I would not know, its a fact that gearbox parts are not cheap, but it is, what it is, I guess.

And runs very quiet.

Shot is taken between the shifter rails, and the angle of the gear teeth are quite evident, If I ever required replacements, I would certainly look to the same gear design.

I don't know the early history of the gear box, whether it was built from parts obtained from the UK, (This would have been in the 1970s) Or if the likes of local Aussie gearbox manufacturer's, Peter Holinger or perhaps others machined/supplied the bits.

There are several engineering places around who would be capable of the CNC machining process, but at what cost I would not know, its a fact that gearbox parts are not cheap, but it is, what it is, I guess.

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

The ratios are indeed superb and I find no difficulty getting off the line even in a lardy Plus 2, in fact it feels no different to the previous semi close box other than I can do 50 in first!

On balance I find the increased noise of the MKF box an acceptable trade off for the excellent ratios.

On balance I find the increased noise of the MKF box an acceptable trade off for the excellent ratios.

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

41 posts

• Page 2 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 33 guests