Fith in five

16 posts

• Page 1 of 2 • 1, 2

Gentlemen and nerds,

Allow me to share a worthwhile mod. to the Lotus five- gearbox.

For many years the downshift from 5th. gear has been very heavy. ( on all three of those I have been involved with )

In other respects I think I have a very nice gearbox these days with some upgrading / developments during a couple of rebuilds through the years addressing different issues.

By reducing preload on the locking pin spring supported by the domed nut in the bottom ( by ca. 30% ) I have now a fifth gear action almost comparable to the other 4 gears. I also rounded of the shape of the contact area of same locking pin. The 135 dg. contact point is now a much smoother round contact.

Yes I know that the contact is still a point, but all the same It felt much smoother when comparing with a surplus bottom shifter shaft.

I was a little apprehensive if it should be prone to jumping out of gear. So far it work very nice.

As I have no access to a large inventory of springs I made a deeper dome nut on my lathe, adding ca 5mm for the spring.

Enjoy

Best regards C.Garde

s muci rpish" releaving the years R

Allow me to share a worthwhile mod. to the Lotus five- gearbox.

For many years the downshift from 5th. gear has been very heavy. ( on all three of those I have been involved with )

In other respects I think I have a very nice gearbox these days with some upgrading / developments during a couple of rebuilds through the years addressing different issues.

By reducing preload on the locking pin spring supported by the domed nut in the bottom ( by ca. 30% ) I have now a fifth gear action almost comparable to the other 4 gears. I also rounded of the shape of the contact area of same locking pin. The 135 dg. contact point is now a much smoother round contact.

Yes I know that the contact is still a point, but all the same It felt much smoother when comparing with a surplus bottom shifter shaft.

I was a little apprehensive if it should be prone to jumping out of gear. So far it work very nice.

As I have no access to a large inventory of springs I made a deeper dome nut on my lathe, adding ca 5mm for the spring.

Enjoy

Best regards C.Garde

s muci rpish" releaving the years R

- c.garde

- Second Gear

- Posts: 59

- Joined: 21 Dec 2011

thank you for your post. I have also attempted to make downshifting from 5 easier by stacking washers (two iirc) under the locking preload spring plug, for a minute improvement only... The gearbox had been overhauled at great expense (but poorly chosen location, my mistake), and I'm still suspecting that there must be something else than just that locking spring causing the trouble (very difficult to disengage when hot - so I don't use it for track days).

I will look into smoothing the pin round next time I fiddle with it, in case I can get an other incremental improvement whatever moderate it may be...

I will look into smoothing the pin round next time I fiddle with it, in case I can get an other incremental improvement whatever moderate it may be...

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

JonB wrote:A picture or diagram would help me understand this mod. .

INdeed. I'm confused. C.Garde mentions reducing preload on a particular spring but

Nmadult mentions adding shims under a preload spring, which, in my mind, makes the

spring stiffer. My disengagement from 5th isn't too bad but stiffer than the other gears.

Greg Z

45/0243K Sprint

45/7286 S3 SE DHC

45/0243K Sprint

45/7286 S3 SE DHC

-

gjz30075 - Coveted Fifth Gear

- Posts: 3022

- Joined: 12 Sep 2003

Thank you for comments and Qs.

No need for drawings , this is so simple.

I turned down the domed part of the bolt to a cylindrical shape. Onto this I solderes an elongation with a hole for the newly formed tap. Hole ( supporting the spring ) bored to the desired depth.

I started out with + 5 mm, thus reducing preload ca 30% . It might be even deeper for further

ease of action . However watch out for jumping out of gear.

A thought for those who does not have access to a lathe . ( poor fellows )

)

A bolt to size could be a great help to work out optimal reduction of preload. ( dont know if the thread is metric or imp.. ? 11/16 or 16 mm ? . part fro BL )

Just drill out center to a depth of say 35 mm.

This can be locked to the bottom of gearbox with a thin nut.

Hardly oil tight but fine for experimentations.

Dimensions:

Free length of spring 43 mm.

? 9,5 mm

Coils : 17

Wire : 1,5 mm ( for those with a box of springs )

Threaded part of domed bolt : 12 mm.

depth of hole in bolt : ( 12 ) + 13 mm .

Hoping this will be of some help.

I am looking forward to reports of optimal reduction of preload.

Qs / answers:

The suggested shimming is of course under the bolt head.

Bear in mind that this is not safe in the long run .( A safe thread is no less than ? )

I do not have any suggestions for the very heavy shift reported.

This can be caused of both a tight and a very loose fit from top to bottom.

( and of course the subject for this discussion . You could loosen up the domehead 10mm to see what happens ? )

Mr Burton is probably the best choice for all thing 5-gear . Did a fine job on my diff. for a very reasonable cost. The only thing I dont do myself )

( just around the corner from club H.Q. )

Best regards c.garde

No need for drawings , this is so simple.

I turned down the domed part of the bolt to a cylindrical shape. Onto this I solderes an elongation with a hole for the newly formed tap. Hole ( supporting the spring ) bored to the desired depth.

I started out with + 5 mm, thus reducing preload ca 30% . It might be even deeper for further

ease of action . However watch out for jumping out of gear.

A thought for those who does not have access to a lathe . ( poor fellows

A bolt to size could be a great help to work out optimal reduction of preload. ( dont know if the thread is metric or imp.. ? 11/16 or 16 mm ? . part fro BL )

Just drill out center to a depth of say 35 mm.

This can be locked to the bottom of gearbox with a thin nut.

Hardly oil tight but fine for experimentations.

Dimensions:

Free length of spring 43 mm.

? 9,5 mm

Coils : 17

Wire : 1,5 mm ( for those with a box of springs )

Threaded part of domed bolt : 12 mm.

depth of hole in bolt : ( 12 ) + 13 mm .

Hoping this will be of some help.

I am looking forward to reports of optimal reduction of preload.

Qs / answers:

The suggested shimming is of course under the bolt head.

Bear in mind that this is not safe in the long run .( A safe thread is no less than ? )

I do not have any suggestions for the very heavy shift reported.

This can be caused of both a tight and a very loose fit from top to bottom.

( and of course the subject for this discussion . You could loosen up the domehead 10mm to see what happens ? )

Mr Burton is probably the best choice for all thing 5-gear . Did a fine job on my diff. for a very reasonable cost. The only thing I dont do myself )

( just around the corner from club H.Q. )

Best regards c.garde

- c.garde

- Second Gear

- Posts: 59

- Joined: 21 Dec 2011

gjz30075 wrote:Nmadult mentions adding shims under a preload spring, which, in my mind, makes the

spring stiffer.

not under the spring, under the "spring plug" or whatever it is called : it looks like a large blind nut iirc, the spring rests at the bottom of the blind hole and the other end of the spring pushes on the detent, so if one adds washers the spring pushes less on the detent.

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

Is it the crossgate plunger mechanism? Itesms 5,6 and 7 in the diagram: http://www.lotuselan.net/wiki/FD_-_Gear ... ifter_%2B2

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

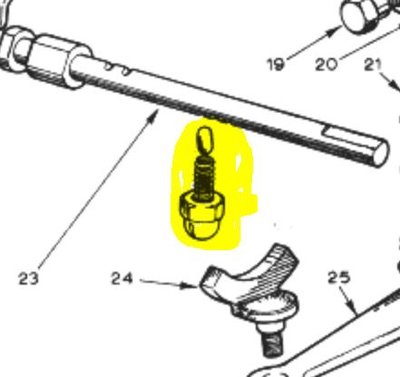

You will see the plunger/ spring pictured between no. 23 og 24 .

You are referring to the crossgate spring protecting the rear gear position.

A different issue might be a slight spring load to the shifter the opposite direction helping slotting 3-4.

I have an idea for this. Very simple but not made in situ.

best regards c.garde.

You are referring to the crossgate spring protecting the rear gear position.

A different issue might be a slight spring load to the shifter the opposite direction helping slotting 3-4.

I have an idea for this. Very simple but not made in situ.

best regards c.garde.

- c.garde

- Second Gear

- Posts: 59

- Joined: 21 Dec 2011

Should be a (visible) copper washer under the nut. You'll lose some fluid that has found it way there and maybe a steady drip while there nut is removed. Wasn't much fluid when I did it, few mm in small plastic pot.

You probably want everything ready so you can remove and refit quickly but should be no need to drain the box or top up afterwards.

You probably want everything ready so you can remove and refit quickly but should be no need to drain the box or top up afterwards.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

Gentlemen +Nerds,

I have now enjoyed my latest mod. for a couple of months. The easier engagement of 5/ reverse is a big improvement, however still heavier than the first four gears.

In search for an even softer engagement I have found a spring off the shelf that seems to do the job.

Please bear in mind that this spring is supportet by my modified domenut itself 5 mm deeper than std.

Thus the initial preload is reduced by ca. a third .Added to this is now a new softer spring. ( shorter by 2mm )

This is a mess to everybody but me . The proper solution would ofcourse be a different ( softer ) spring + std domenut.

I am sure that a co-nerd would be better qualified to define the proper spring to use for this VERY welcome improvement. The shift is now very much the same in all gears.

I have not experienced any problems with disengagement of gears .

The spring I found is

HS code 7320208100 made in UK.

d 1.19

Matr. C din 17223 ( " pianowire " )

De 9.14

L0 38,10

No. of coils 11,5 in all.

If you replace the original spring with this you will already get an impression of the scope.

Finally be aware that Lotus modified the retaining grooves on later boxes.

This might have some importance.

Enjoy C.Garde

I have now enjoyed my latest mod. for a couple of months. The easier engagement of 5/ reverse is a big improvement, however still heavier than the first four gears.

In search for an even softer engagement I have found a spring off the shelf that seems to do the job.

Please bear in mind that this spring is supportet by my modified domenut itself 5 mm deeper than std.

Thus the initial preload is reduced by ca. a third .Added to this is now a new softer spring. ( shorter by 2mm )

This is a mess to everybody but me . The proper solution would ofcourse be a different ( softer ) spring + std domenut.

I am sure that a co-nerd would be better qualified to define the proper spring to use for this VERY welcome improvement. The shift is now very much the same in all gears.

I have not experienced any problems with disengagement of gears .

The spring I found is

HS code 7320208100 made in UK.

d 1.19

Matr. C din 17223 ( " pianowire " )

De 9.14

L0 38,10

No. of coils 11,5 in all.

If you replace the original spring with this you will already get an impression of the scope.

Finally be aware that Lotus modified the retaining grooves on later boxes.

This might have some importance.

Enjoy C.Garde

- c.garde

- Second Gear

- Posts: 59

- Joined: 21 Dec 2011

and if you go too far , you'll find out what it feels like changing from 5th to reverse in one easy move...

John

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

16 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 16 guests