Help me understand the Anti-Sizzle gear lever...

36 posts

• Page 1 of 3 • 1, 2, 3

I am un-bodging my gear lever, but I did not have all the original parts & I am having trouble understanding how the assembly works.

The gear lever has a rubber isolator with a metal bushing that is not bonded to it & so can rotate within it.. The metal bushing is about .125" longer than the rubber.

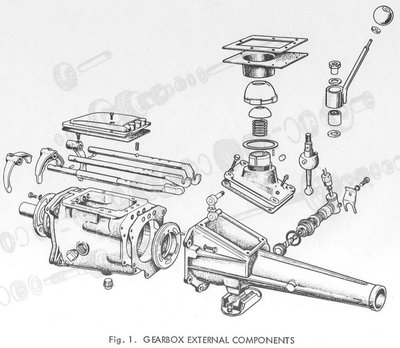

Here's an exploded view of the assembly

If I place a washer with an ID smaller than the OD of the bushing sleeve above & below that isolator the sleeve nut clamps down on the metal sleeve in the bushing, but then the gear lever can rotate.

Should the 2 washers (I do not have the original lotus parts) have an id larger than the metal sleeve in the bushing, so that when you tighten the sleeve nut it squashes the rubber bushing tightening up the assembly?

If my description is too difficult to understand I will model the assembly & post cross section drawings.

The gear lever has a rubber isolator with a metal bushing that is not bonded to it & so can rotate within it.. The metal bushing is about .125" longer than the rubber.

Here's an exploded view of the assembly

If I place a washer with an ID smaller than the OD of the bushing sleeve above & below that isolator the sleeve nut clamps down on the metal sleeve in the bushing, but then the gear lever can rotate.

Should the 2 washers (I do not have the original lotus parts) have an id larger than the metal sleeve in the bushing, so that when you tighten the sleeve nut it squashes the rubber bushing tightening up the assembly?

If my description is too difficult to understand I will model the assembly & post cross section drawings.

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

While we wait for someone who knows what they are talking about I'd comment that the rubber bushing in my lever doesn't turn. It's bonded firmly inside the tubular bit at the end of the gear lever. When you place it over the verticle stub coming from the gearbox you can rotate the lever through an arc (for personal positional preference) until you tighten down the nut. Then it stays put.

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

There is no hole through the lower piece or any other piece for that matter, I have seen pictures on lotuselan.net though that shows the hole that you are talking about.

So rephrasing my question:

1. Should the ID of the washer below be larger than the OD of the metal sleeve?

-or-

2. Should the metal sleeve have been bonded to the rubber bushing.

That's the only way that I can see this assembly working!

So rephrasing my question:

1. Should the ID of the washer below be larger than the OD of the metal sleeve?

-or-

2. Should the metal sleeve have been bonded to the rubber bushing.

That's the only way that I can see this assembly working!

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

On mine the rubber is bonded to an inner sleeve and outer sleeve that is pressed into the lever base. I have never removed it but it looks very similar to a front wishbone bush I don't know if its the same as never measured it up. The locating nut is a special sleeved nut arrangement as shown in the drawing that screws in as tight fit into the top of the bushing inner sleeve. The washers fit inside the based of the lever to limit movement of the lever on the rubber.

Also no roll pin or hole in mine

cheers

Rohan

Also no roll pin or hole in mine

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Kev,

The Elan does not have a roll pin but the +2 does, well I use a split pin. The levers are quite different at the bottom where they attach to piece that fits into the gear box. I'll try to find some pics later on, unless someone else beats me to it.

Cheers

John

The Elan does not have a roll pin but the +2 does, well I use a split pin. The levers are quite different at the bottom where they attach to piece that fits into the gear box. I'll try to find some pics later on, unless someone else beats me to it.

Cheers

John

- elanman999

- Fourth Gear

- Posts: 500

- Joined: 12 Nov 2005

elanman999 wrote:Kev,

The Elan does not have a roll pin but the +2 does, well I use a split pin. The levers are quite different at the bottom where they attach to piece that fits into the gear box. I'll try to find some pics later on, unless someone else beats me to it.

Cheers

John

Thanks John, I thought for a while I had another bodge on the car.

I'm finding so many things lately that aren't standard, I can't tell anymore. The best one I've found is the boot lock mechanism missing (no lock at all!) but wired up to a horn under the bonnet as an anti theft device

Kev.

- KevJ+2

- Fourth Gear

- Posts: 641

- Joined: 23 Aug 2013

Phil.. Order a new rubber bush...

Your problem is the metal inner sleeve of the bush (as you now know) should not be a loose part. It should be firmly bonded into the rubber as Rohan has stated and (like a wishbone bush) it should be a very tight fit in the gearstick and requires pressing into position. Don't use any heat. Burning rubber smells lousy.

If you mentally picture the bush (before being pressed into the lever), it should be firmly clamped onto the box shift lever ass'y. The lower part of this lever (where the bush sits) should be a nice sliding fit into the bottom of the rubber bushe's inner sleeve. The special sleeved nut I sent you should also be a slip fit from the top down into the bush and screw locate onto the top of the shift lever. Tighten the sleeve nut now and the rubber bush should now be clamped firmly to the box shift lever.... Now imagine the gearstick in place on that ass'y.. For easy understanding.

The washers (top and bottom of the rubber bush) should be a slightly smaller diameter (a mm or two) than the OUTER metal sleeve of the rubber bush ass'y. & must not touch the inside of the shift lever allowing some clearance. The lever should be 'floating' (flexable / Isolated) on the rubber bush. No part of the gearstick should be in metal to metal contact with the box shift lever.. So no vibes travel up the gearstick to the knob...

When assembled right you should be able to move the gearlever around a little on the rubber bush.

Clear as mud?

Hope this helps. Did you check that the sleeve nut fits the thread on top of the box shift (stubby bit with ball)? and that it fits into the rubber bush inner sleeve? It must do this.

Cheers all ....

Your problem is the metal inner sleeve of the bush (as you now know) should not be a loose part. It should be firmly bonded into the rubber as Rohan has stated and (like a wishbone bush) it should be a very tight fit in the gearstick and requires pressing into position. Don't use any heat. Burning rubber smells lousy.

If you mentally picture the bush (before being pressed into the lever), it should be firmly clamped onto the box shift lever ass'y. The lower part of this lever (where the bush sits) should be a nice sliding fit into the bottom of the rubber bushe's inner sleeve. The special sleeved nut I sent you should also be a slip fit from the top down into the bush and screw locate onto the top of the shift lever. Tighten the sleeve nut now and the rubber bush should now be clamped firmly to the box shift lever.... Now imagine the gearstick in place on that ass'y.. For easy understanding.

The washers (top and bottom of the rubber bush) should be a slightly smaller diameter (a mm or two) than the OUTER metal sleeve of the rubber bush ass'y. & must not touch the inside of the shift lever allowing some clearance. The lever should be 'floating' (flexable / Isolated) on the rubber bush. No part of the gearstick should be in metal to metal contact with the box shift lever.. So no vibes travel up the gearstick to the knob...

When assembled right you should be able to move the gearlever around a little on the rubber bush.

Clear as mud?

Hope this helps. Did you check that the sleeve nut fits the thread on top of the box shift (stubby bit with ball)? and that it fits into the rubber bush inner sleeve? It must do this.

Cheers all ....

Alex Black.

Now Sprintless!!

Now Sprintless!!

-

alexblack13 - Coveted Fifth Gear

- Posts: 2076

- Joined: 17 Oct 2007

Thanks guys, looks like the new bushing supplied with my gear lever from JAE is the issue.

I'll see if I can get a new one from Matty's.

That can't happen on mine! The OD of the lever is larger than the ID of the bush, but fits your sleeve nut perfectly... I wonder if the lever was modified as well?....

My bushing has no outer metal sleeve! But I understand that the washer just acts to limit travel. Is the ID of the washer smaller or larger than the OD of the inner sleeve?

That's the one thing that works perfectly!

Thanks as ever for all the help...

I'll see if I can get a new one from Matty's.

alexblack13 wrote:Phil.. The lower part of this lever (where the bush sits) should be a nice sliding fit into the bottom of the rubber bushe's inner sleeve. ......

That can't happen on mine! The OD of the lever is larger than the ID of the bush, but fits your sleeve nut perfectly... I wonder if the lever was modified as well?....

alexblack13 wrote: The washers (top and bottom of the rubber bush) should be a slightly smaller diameter (a mm or two) than the OUTER metal sleeve of the rubber bush ass'y.....

My bushing has no outer metal sleeve! But I understand that the washer just acts to limit travel. Is the ID of the washer smaller or larger than the OD of the inner sleeve?

alexblack13 wrote: Did you check that the sleeve nut fits the thread on top of the box shift (stubby bit with ball)? and that it fits into the rubber bush inner sleeve? It must do this.

That's the one thing that works perfectly!

Thanks as ever for all the help...

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

Get back to us if you need those questions answered Phil.. Having a pattern should explain all.

The assembly should be... Onto the gearshift (into g/box) lever..

Travel limiting washer 1st then the gearstick then the next travel limit washer then down through the washer into the bush goes the sleeve nut which screws onto the gearshift. Tighten firmly.. PITA when the thing comes slack and you are out on the road..

Al' ...

The assembly should be... Onto the gearshift (into g/box) lever..

Travel limiting washer 1st then the gearstick then the next travel limit washer then down through the washer into the bush goes the sleeve nut which screws onto the gearshift. Tighten firmly.. PITA when the thing comes slack and you are out on the road..

Al' ...

Alex Black.

Now Sprintless!!

Now Sprintless!!

-

alexblack13 - Coveted Fifth Gear

- Posts: 2076

- Joined: 17 Oct 2007

alexblack13 wrote: PITA when the thing comes slack and you are out on the road..

Al' ...

Not as bad as when the whole thing shears off!

I was thinking of adding a jamb nut above the sleeve nut to encourage it not to come loose.

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

Yep.. Good thinking. We call that a 'lock nut' ....Well worth it.

Al' ....

Al' ....

Alex Black.

Now Sprintless!!

Now Sprintless!!

-

alexblack13 - Coveted Fifth Gear

- Posts: 2076

- Joined: 17 Oct 2007

36 posts

• Page 1 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 23 guests