S4 DHC trunk (boot) layout

24 posts

• Page 2 of 2 • 1, 2

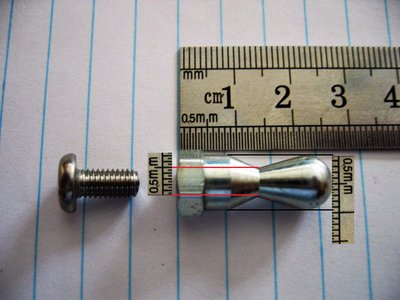

oldelanman wrote:Screw thread measures 3/16" diameter x 32 tpi (10.32 UNF ?) but if you're making one up it really doesn't matter what thread you use.

Originally this might be a 2BA screw (0.185" diameter and 31.4 threads per inch). BA screws are very common on trim pieces. Of course, as noted, you can do what you please if you are making your own.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

Rick,

The genuine article can still be had. I got mine from Paul Matty in the UK.

Regards,

Colin.

The genuine article can still be had. I got mine from Paul Matty in the UK.

Regards,

Colin.

YellowS4DHC wrote:Roger

thanks for the photo and specs. I figure I can just grind down a ss bolt and get a pretty close copy.

Rick

'69 Elan S4 DHC

'57 T1 Speedster

'67 S800 Coupe

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 631

- Joined: 04 Oct 2003

fatboyoz wrote:Rick, The genuine article can still be had. I got mine from Paul Matty in the UK.

Regards,

Colin.

Yes, that was going to be my next question. Thanks, Colin. Roger, thank you again for taking the time to post the patterns and photos. I hope to be able to make my patterns this weekend on cardboard.

I may just have the peg machined in stainless steel. Here is Roger's excellent photo, which I altered a bit to show the machine shop the thickness of the shank. Would that be about right?

Andy

- abstamaria

- Third Gear

- Posts: 301

- Joined: 12 Nov 2010

Roger (oldelanman), thanks for posting the pattern for the boot floor.

I made one up this weekend for my S4 DHC and the fit is good. My fuel tank is mounted slightly angled with respect to the centerline of the car, rearward portion outward (possibly modified to allow storage of a larger wheel somewhere along the line), which results in a tapered gap between the new floor board and the tank. I think I will leave it as is because I cover the whole area with a carpet anyway.

I discarded my original board some twenty odd years ago because it was an ugly, non-function-able piece (not even sure if it was plywood), fortunately I kept the two latch parts. The new floorboard makes things look much better.

I made one up this weekend for my S4 DHC and the fit is good. My fuel tank is mounted slightly angled with respect to the centerline of the car, rearward portion outward (possibly modified to allow storage of a larger wheel somewhere along the line), which results in a tapered gap between the new floor board and the tank. I think I will leave it as is because I cover the whole area with a carpet anyway.

I discarded my original board some twenty odd years ago because it was an ugly, non-function-able piece (not even sure if it was plywood), fortunately I kept the two latch parts. The new floorboard makes things look much better.

Alex

45/8236

Redwood City, CA

45/8236

Redwood City, CA

-

Yum-yum - Second Gear

- Posts: 57

- Joined: 25 Mar 2008

Yum-yum wrote:Roger (oldelanman), thanks for posting the pattern for the boot floor.

Thanks Alex, my pleasure. Glad it was useful to you - and a few others as well it seems. Thanks for taking the time to post your results.

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1930

- Joined: 02 Jan 2008

I had two pegs machined in stainless steel by a friend of mine, based on Roger's (Oldelanman's) photo. As I mentioned, my Elan was always missing this item.

Many thanks, Roger, all.

Andy

Many thanks, Roger, all.

Andy

- abstamaria

- Third Gear

- Posts: 301

- Joined: 12 Nov 2010

Very nice Andy.

I'm sure you've already thought of it but it's a good idea to use a thin washer either side of the plywood when you fit the peg so it doesn't pull through - the spring clip holds the peg really tightly and needs a good sharp tug on the boot board to release it.

I'm sure you've already thought of it but it's a good idea to use a thin washer either side of the plywood when you fit the peg so it doesn't pull through - the spring clip holds the peg really tightly and needs a good sharp tug on the boot board to release it.

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1930

- Joined: 02 Jan 2008

Thanks, Roger. I won't forget to use washers.

Best,

Andy

Best,

Andy

- abstamaria

- Third Gear

- Posts: 301

- Joined: 12 Nov 2010

oldelanman wrote:Very nice Andy.

I'm sure you've already thought of it but it's a good idea to use a thin washer either side of the plywood when you fit the peg so it doesn't pull through - the spring clip holds the peg really tightly and needs a good sharp tug on the boot board to release it.

Yep. That's why I had to replace the board. As bought mine had a countersunk screw which was soon left behind...

Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

24 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: 3261R and 7 guests