Not a lot happened this last week or so as life has got in the way. Converting garage into two flats for kids and revamping the conservatory after new roof fitted.

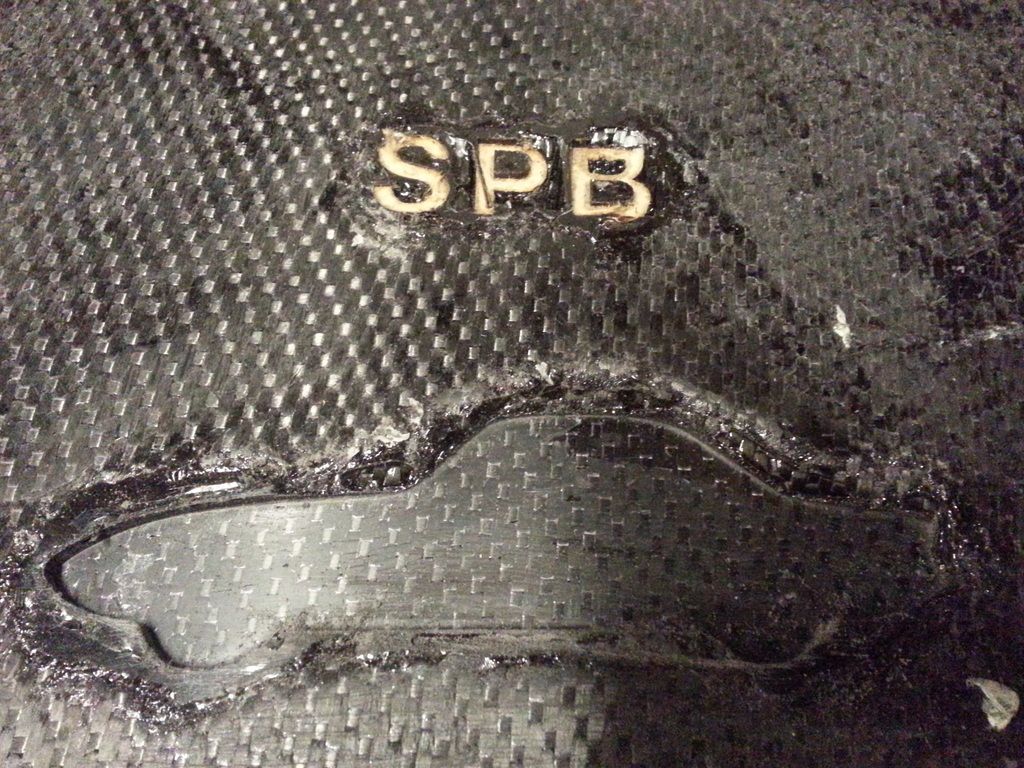

Anyway, I have now started on my third attempt to make my seat. This time I will use 4 layers of carbon and 5mm thick dense foam filling. Mould has been prepared so, hopefully, I will lay up and vacuum tomorrow.

Finished the mould for the wing vents. Couldn't find any that had the opening I wanted, they are either 6mm or huge. I wanted around 14mm so decided to make my own, then I will get what I want rather than having to compromise.

All I am now missing is the top layer of prepreg carbon. This isn't cheap so I have been putting it off until I am ready for it.