Re: Bill's 26S

Hi Sandy,

My cast aluminum wheels likely weigh more that my steel rims, but the aluminum wheels will be stronger, truer, and wider (6 vs 4.5 inches wde) and the aluminum KO spinners will be lighter than the chromed bronze ones. All in all, I think I?m ok with the tradeoffs.

Hi DavidB,

I?m still waiting for my steering rack assembly to be rebuilt using the shortened26R rack. The following photo compares the standard rack with the shortened (-0.5 inch) rack. For a given toe in setting, each track rod will be ? inch longer. When rack height is properly adjusted, this additional tie rod length desensitizes the tendency to toe in on bump and droop.

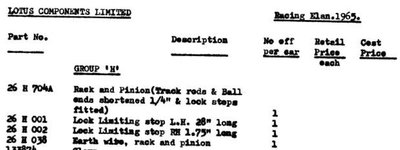

The following 1965 26R parts list references changes to rack assembly length in the Wiki section.

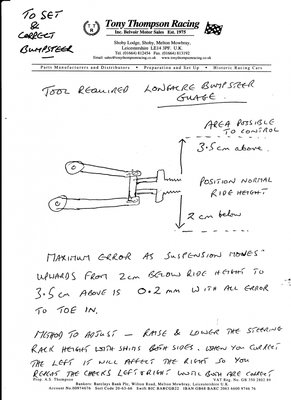

TTR provided the following instructions for minimizing bump steer some time back. I can confirm that rack height adjustment can virtually eliminate bump steer over the indicated 5.5 cm range. Outside this range, my suspension began to toe in. I believe the shorter rack will delay the onset of toe in over a larger range, which could be important for a street car.

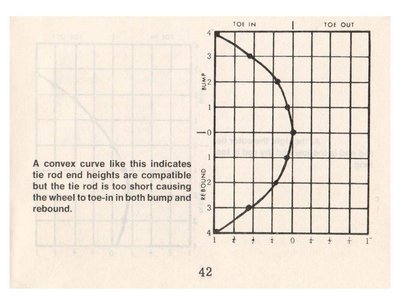

The diagram below is from Steve Smith?s book, ?Advanced Race Car Suspension Development?. My laser measurement system produces a trace as shown below. TTR?s bump steer range is -0.8 (-2 cm) to +1.38 (+3.5 cm) inches, droop to bump. With the rack height properly set, this range shows almost no toe change. Exceed this range, and toe in is apparent. This curve is for the right (starboard) wheel when the tie rod is mounted in front of the spindle. The tie rod is shorter than optimum. A shorter rack paired with a longer tie rod, mitigates toe in change on the Elan. Perfect lengths and angles would yield a straighter, vertical, deflection line.

The other thing TTR told me was to stick with the standard front anti roll bar for fast street use and if necessary switch to a stiffer one for track days. I believe a stiffer front bar by itself promotes understeer, all else being the same. TTR recommends letting the springs and dampers control roll and weight transfer. I have TTR front and rear fast road dampers and springs on the shelf. TTR says the initial front damper settings should be 5 (10 max) clicks from full soft and the rears should be 1 turn from full soft IIRC. Initial front toe in should be 1/8 inch total and initial rear toe in should be 3/16 inch total. All these setting will have to be done after installation of the new rack and painting of the chassis. For now we are at best close on caster, camber, and toe in at the front. I have not yet be fitted the rear A-arms.

TTR again recommend the Avon CR6ZZ tires in 185/70R13 size for my street application. This is an all-weather tire with a competition compound and I believe a more rounded cross section. The overall diameter is the same as the RA1?s. The problem is cost and availability in the USA.

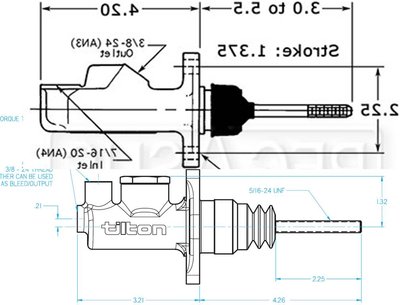

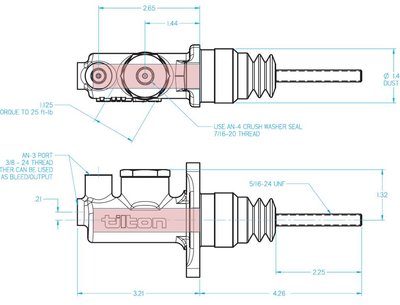

In addition to the new rack, I am waiting for the new Tilton master cylinder for the clutch master cylinder. The following drawing compares the Tilton with the Girling I currently have. It turns out the master cylinder blister is currently the limiting factor to full left lock. The Tilton should give just enough clearance so that the front anti roll bar becomes the limiting factor for full lock, but in reality the S4-Sprint lock limiter may turn out to be just right.

The colored volume in the following drawing represents my best guess of the actual 0.625 inch bore. This master cylinder is not only shorter but it appears that the end of the casting can be chamfered for additional tire clearance.

Bill

My cast aluminum wheels likely weigh more that my steel rims, but the aluminum wheels will be stronger, truer, and wider (6 vs 4.5 inches wde) and the aluminum KO spinners will be lighter than the chromed bronze ones. All in all, I think I?m ok with the tradeoffs.

Hi DavidB,

I?m still waiting for my steering rack assembly to be rebuilt using the shortened26R rack. The following photo compares the standard rack with the shortened (-0.5 inch) rack. For a given toe in setting, each track rod will be ? inch longer. When rack height is properly adjusted, this additional tie rod length desensitizes the tendency to toe in on bump and droop.

The following 1965 26R parts list references changes to rack assembly length in the Wiki section.

TTR provided the following instructions for minimizing bump steer some time back. I can confirm that rack height adjustment can virtually eliminate bump steer over the indicated 5.5 cm range. Outside this range, my suspension began to toe in. I believe the shorter rack will delay the onset of toe in over a larger range, which could be important for a street car.

The diagram below is from Steve Smith?s book, ?Advanced Race Car Suspension Development?. My laser measurement system produces a trace as shown below. TTR?s bump steer range is -0.8 (-2 cm) to +1.38 (+3.5 cm) inches, droop to bump. With the rack height properly set, this range shows almost no toe change. Exceed this range, and toe in is apparent. This curve is for the right (starboard) wheel when the tie rod is mounted in front of the spindle. The tie rod is shorter than optimum. A shorter rack paired with a longer tie rod, mitigates toe in change on the Elan. Perfect lengths and angles would yield a straighter, vertical, deflection line.

The other thing TTR told me was to stick with the standard front anti roll bar for fast street use and if necessary switch to a stiffer one for track days. I believe a stiffer front bar by itself promotes understeer, all else being the same. TTR recommends letting the springs and dampers control roll and weight transfer. I have TTR front and rear fast road dampers and springs on the shelf. TTR says the initial front damper settings should be 5 (10 max) clicks from full soft and the rears should be 1 turn from full soft IIRC. Initial front toe in should be 1/8 inch total and initial rear toe in should be 3/16 inch total. All these setting will have to be done after installation of the new rack and painting of the chassis. For now we are at best close on caster, camber, and toe in at the front. I have not yet be fitted the rear A-arms.

TTR again recommend the Avon CR6ZZ tires in 185/70R13 size for my street application. This is an all-weather tire with a competition compound and I believe a more rounded cross section. The overall diameter is the same as the RA1?s. The problem is cost and availability in the USA.

In addition to the new rack, I am waiting for the new Tilton master cylinder for the clutch master cylinder. The following drawing compares the Tilton with the Girling I currently have. It turns out the master cylinder blister is currently the limiting factor to full left lock. The Tilton should give just enough clearance so that the front anti roll bar becomes the limiting factor for full lock, but in reality the S4-Sprint lock limiter may turn out to be just right.

The colored volume in the following drawing represents my best guess of the actual 0.625 inch bore. This master cylinder is not only shorter but it appears that the end of the casting can be chamfered for additional tire clearance.

Bill