Cosworth YB Turbo Into Elan

pauljones wrote:Amazing stuff Steve.

Thanks Paul. I am quite chuffed with my efforts. Not bad for a retired Council highway engineer in a shed with no training

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

stevebroad wrote:pauljones wrote:Amazing stuff Steve.

Thanks Paul. I am quite chuffed with my efforts. Not bad for a retired Council highway engineer in a shed with no trainingIf only I could get the hang of TIG welding.

I went to night school for one night a week, fourteen weeks. TIGtastic now.

Graeme

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

-

661 - Coveted Fifth Gear

- Posts: 1197

- Joined: 29 Mar 2012

661 wrote:stevebroad wrote:pauljones wrote:Amazing stuff Steve.

Thanks Paul. I am quite chuffed with my efforts. Not bad for a retired Council highway engineer in a shed with no trainingIf only I could get the hang of TIG welding.

I went to night school for one night a week, fourteen weeks. TIGtastic now.

I've got a job for you - fancy welding a set of toe in adjustment turnbuckles onto my A arms?

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

661 wrote:stevebroad wrote:pauljones wrote:Amazing stuff Steve.

Thanks Paul. I am quite chuffed with my efforts. Not bad for a retired Council highway engineer in a shed with no trainingIf only I could get the hang of TIG welding.

I went to night school for one night a week, fourteen weeks. TIGtastic now.

Where did you go?

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

661 wrote:stevebroad wrote:

Where did you go?

I went to Plumpton College, but if you google TIG courses in Essex, something close will come up.

City and Guilds Level 1 no less !

I have found a few. I would prefer an evening course if possible and still looking.

I saw Plumpton College and wondered where it was

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

pauljones wrote:Steve.

I cant wait to see that Carbon front end. Carefull it doesnt float away.

Paul

Unfortunately, I can't make it that light, but I will try my best

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

I love it when something you make for one task can be adapted for others.

I have been looking into making the Lexan windows. The door panes are easy as they are flat. The front and rear screens are, however, quite curved. Lexan, fortunately, can be heat formed at a temperature that I can achieve in my carbon fibre curing oven.

Plan:

Make a mould using original glass, cover in felt, lay on Lexan, enclose in a vacuum bag and place in oven, warm up oven and then gradually evacuate the bag, once Lexan has conformed to mould allow to cool. Seems easy enough

I have been looking into making the Lexan windows. The door panes are easy as they are flat. The front and rear screens are, however, quite curved. Lexan, fortunately, can be heat formed at a temperature that I can achieve in my carbon fibre curing oven.

Plan:

Make a mould using original glass, cover in felt, lay on Lexan, enclose in a vacuum bag and place in oven, warm up oven and then gradually evacuate the bag, once Lexan has conformed to mould allow to cool. Seems easy enough

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

gav wrote:Steve

if you are feeling flush Plastics for Performance do screens. I was tempted by the scratch resistant ones but was put off by the price.

Gavin

Hi Gavin

Yeah, I looked at these when I decided to go plastic. Unfortunately my screens need to be bigger than standard in order to do away with the rubber seal. Also, the cost is ?200 more than making your own - if you have the facilities (which i have).

There is also the satisfaction of making them yourself

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

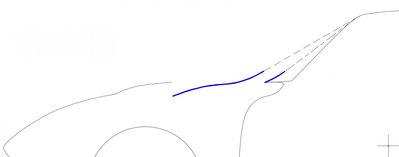

I have been having an interesting FB messenger discussion with my aero guru regarding getting the hot rad and engine air out of the engine bay. The area of the vent opening needs to be approx 40% of the area of the rad.

Can't get this using just the rear facing bonnet vent but an additional vent at the rear of the bonnet will make up the shortfall. In order for this to work I have to ameliorate the high pressure zone at the base of the windscreen which could restrict the under bonnet air from exiting. I think we have that sorted.

A bonus will be reduced drag, never a bad thing

Next task is to look at the underside. I need a drip tray but that could be incorporated into the underbody aero panels, thereby making one item do two jobs and keeping additional weight to a minimum Also looking at side splitters and dams.

Can't get this using just the rear facing bonnet vent but an additional vent at the rear of the bonnet will make up the shortfall. In order for this to work I have to ameliorate the high pressure zone at the base of the windscreen which could restrict the under bonnet air from exiting. I think we have that sorted.

A bonus will be reduced drag, never a bad thing

Next task is to look at the underside. I need a drip tray but that could be incorporated into the underbody aero panels, thereby making one item do two jobs and keeping additional weight to a minimum Also looking at side splitters and dams.

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

gav wrote:Steve

Does that mean you will need a lip on the back edge of the bonnet to create a low pressure area behind which the rad air can escape?

Thanks

Gavin

We are looking at something like this. The lip is pointing towards the top of the screen at a 60 degree angle. In order to get this alignment the vent is in from the back edge of the bonnet.

Last edited by stevebroad on Thu Apr 12, 2018 7:26 pm, edited 1 time in total.

- stevebroad

- Fourth Gear

- Posts: 846

- Joined: 08 Mar 2004

Total Online:

Users browsing this forum: No registered users and 1 guest