Re: S1 ?lan Rebuild - My Story

I'm back working on my Elan. Couple of weeks of some video projects and a vacation got me distracted!

Drew came over to help and while I was away I ordered a new gear lever from RD Enterprises so we went about the removal of the old one and installation of the new. The old one had been welded and it looked like someone knew what they were doing as it was a nice job. Never the less, I replaced it.

There was a previous discussion about my mounting bracket for the gearbox. After much deliberation, research, measuring and using a level in various places I determined the fitting that holds the tail of the gearbox in the chassis bracket was custom made and it was sized for the right height of a level gearbox. No need for additional washers.

We decided to remove all the nuts and bolts we used for assembly and put anti-seize on them. In particular on the suspension bolts. I've got grade 8 bolts and washers and nyloc nuts on just about everything. So we jacked up the chassis and spent the morning unbolting, spreading anti-seize and rebolting. Then the bolts and plugs that had been drilled for safety wire all had new wire installed.

After every nut and bolt was retightened we removed the weber carbs, took off the last two sets of intake studs, added the closed cell foam pad to the rear of the chassis and rolled the chassis under the body. Then slowly lowered the body onto the chassis aligning the chassis in small increments to fit. Only one problem. No matter how we positioned the chassis the gear lever would not fit thru the fiberglass hole in the tunnel. So the body went back up and the gear lever was removed. After some minor adjustments moving the chassis (now on hydraulic jacks front and rear) we got it aligned and removed the two post jack support on the body and the floor jacks on the chassis. The car was finally sitting back on its chassis!

We were amazed that everything was aligned exactly as it should be with the bobbins. Spent an hour measuring and walking around the car looking at every area to see what was off. We screwed in the seat belt bolts as they were the only already threaded part on the chassis. They were perfectly aligned so it was time to transfer punch all the bobbin holes.

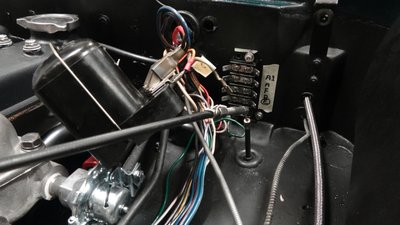

The two bobbin holes that were impossible to transfer punch were the ones behind the dash. I have to replace the fuel gauge (new sending unit in the fuel tank required a recalibrated fuel gauge) and I have a Type 26 replacement crash pad to install and the screws holding the dash in place are the wrong type so we took the dash apart in order to transfer punch the last two bobbin holes.

Drew and I decided to call it a day. We had nine hours of work accomplished, it was almost 90 degrees (F) outside and the humidity was close to 80%. We were wiped out!

Tomorrow we plan on raising the body off the chassis and drilling all the holes and tapping the ones required.

Drew came over to help and while I was away I ordered a new gear lever from RD Enterprises so we went about the removal of the old one and installation of the new. The old one had been welded and it looked like someone knew what they were doing as it was a nice job. Never the less, I replaced it.

There was a previous discussion about my mounting bracket for the gearbox. After much deliberation, research, measuring and using a level in various places I determined the fitting that holds the tail of the gearbox in the chassis bracket was custom made and it was sized for the right height of a level gearbox. No need for additional washers.

We decided to remove all the nuts and bolts we used for assembly and put anti-seize on them. In particular on the suspension bolts. I've got grade 8 bolts and washers and nyloc nuts on just about everything. So we jacked up the chassis and spent the morning unbolting, spreading anti-seize and rebolting. Then the bolts and plugs that had been drilled for safety wire all had new wire installed.

After every nut and bolt was retightened we removed the weber carbs, took off the last two sets of intake studs, added the closed cell foam pad to the rear of the chassis and rolled the chassis under the body. Then slowly lowered the body onto the chassis aligning the chassis in small increments to fit. Only one problem. No matter how we positioned the chassis the gear lever would not fit thru the fiberglass hole in the tunnel. So the body went back up and the gear lever was removed. After some minor adjustments moving the chassis (now on hydraulic jacks front and rear) we got it aligned and removed the two post jack support on the body and the floor jacks on the chassis. The car was finally sitting back on its chassis!

We were amazed that everything was aligned exactly as it should be with the bobbins. Spent an hour measuring and walking around the car looking at every area to see what was off. We screwed in the seat belt bolts as they were the only already threaded part on the chassis. They were perfectly aligned so it was time to transfer punch all the bobbin holes.

The two bobbin holes that were impossible to transfer punch were the ones behind the dash. I have to replace the fuel gauge (new sending unit in the fuel tank required a recalibrated fuel gauge) and I have a Type 26 replacement crash pad to install and the screws holding the dash in place are the wrong type so we took the dash apart in order to transfer punch the last two bobbin holes.

Drew and I decided to call it a day. We had nine hours of work accomplished, it was almost 90 degrees (F) outside and the humidity was close to 80%. We were wiped out!

Tomorrow we plan on raising the body off the chassis and drilling all the holes and tapping the ones required.