Suspension Bush Removal

11 posts

• Page 1 of 1

Stripping down my rear suspension I decided to replace the old rubber bushes with a set of Sue Miller Superflexes (took ALL of my pocket money!).

I have read most of the forum comments on removing old bushes and proceeded to set up suitable (old) sockets on my fitters vice. No way Jose! 3 foot levers and all.

Other suggestions from knowledgeable people (mmmm...) included filing, sawing and blowtorch. I didn't fancy any of these as the rear wishbones are typical Lotus and, to my mind, relatively delicate. The chances of introducing stress raisers by nicking the tubes seemed very difficult to avoid.

After an evenings thought I hit the CAD package, emailed off the drawings to my friendly machinist at 11pm (my garage not big enough for a lathe) and received a call the next day to say that the extractors were in the post.

2 days later snailmail arrived and 2 hours in the garage saw all 8 bushes out VERY cleanly. It could have been quicker, but I designed the extractors to first remove the sleeve plus the rubber and then, with a second operation to remove the troublesome outer sleeves.

I claim nothing original here but I could not find any extractor detail on the forum and thought others might find the information useful. The dimensions I used are not necessarily optimum as they had to be measured with the bushes in place. They do however work!

Anyone interested can PM me for PDF drawings. My man charged me ?50 for the set, including material and is willing to do more but I suspect others may wish to use their own facilities.

(If you are in Surrey, hire my set!)

I have read most of the forum comments on removing old bushes and proceeded to set up suitable (old) sockets on my fitters vice. No way Jose! 3 foot levers and all.

Other suggestions from knowledgeable people (mmmm...) included filing, sawing and blowtorch. I didn't fancy any of these as the rear wishbones are typical Lotus and, to my mind, relatively delicate. The chances of introducing stress raisers by nicking the tubes seemed very difficult to avoid.

After an evenings thought I hit the CAD package, emailed off the drawings to my friendly machinist at 11pm (my garage not big enough for a lathe) and received a call the next day to say that the extractors were in the post.

2 days later snailmail arrived and 2 hours in the garage saw all 8 bushes out VERY cleanly. It could have been quicker, but I designed the extractors to first remove the sleeve plus the rubber and then, with a second operation to remove the troublesome outer sleeves.

I claim nothing original here but I could not find any extractor detail on the forum and thought others might find the information useful. The dimensions I used are not necessarily optimum as they had to be measured with the bushes in place. They do however work!

Anyone interested can PM me for PDF drawings. My man charged me ?50 for the set, including material and is willing to do more but I suspect others may wish to use their own facilities.

(If you are in Surrey, hire my set!)

It's not a rehearsal

- Gopherit

- Second Gear

- Posts: 64

- Joined: 18 Oct 2007

If you can press the inner sleeve & rubber out (or even burn it away if you're brave/reckless!  ) then a CAREFUL saw cut most of the way through the outer sleeve should allow them to fracture & push out 'easily'.

) then a CAREFUL saw cut most of the way through the outer sleeve should allow them to fracture & push out 'easily'.

But you can't beat custom tools - which will probably be lost or borrowed by the time you need them again...

Matthew

Matthew

But you can't beat custom tools - which will probably be lost or borrowed by the time you need them again...

- ppnelan

- Fourth Gear

- Posts: 691

- Joined: 16 Sep 2003

Is it possible for you to post the pdf to the site? Suspension is my next project, front and rear. If not, my email address is [email protected] Thanks. Dan

-

collins_dan - Coveted Fifth Gear

- Posts: 1102

- Joined: 09 Jan 2006

Matthew, Dan et al,

Special tools really make a difference. Pictures and drgs of these ideally should be posted in the Technical Tips directory. Not sure how this can be done though.

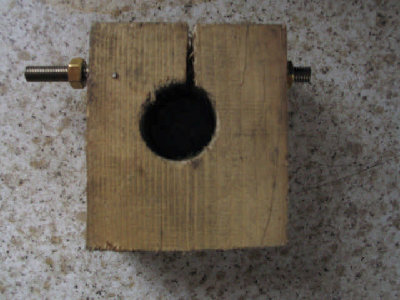

My photo attached was for the wooden clamp used to hold the soft aluminium of the steering column outer. Its just a hole through soft pine, a saw cut and a thread. I got the idea from Brian Buckland's book but wood was to hand and a lot easier to "machine"

Special tools really make a difference. Pictures and drgs of these ideally should be posted in the Technical Tips directory. Not sure how this can be done though.

My photo attached was for the wooden clamp used to hold the soft aluminium of the steering column outer. Its just a hole through soft pine, a saw cut and a thread. I got the idea from Brian Buckland's book but wood was to hand and a lot easier to "machine"

- gerrym

- Fourth Gear

- Posts: 882

- Joined: 25 Jun 2006

Please could forum members requesting drgs include their email address in the request.

It seems I cannot PM more than 2 attachments and anyway it's a pain doing it that way - I should be in the garage, trying to get on the road for April 20th "Drive your Classic Car Day"!

It seems I cannot PM more than 2 attachments and anyway it's a pain doing it that way - I should be in the garage, trying to get on the road for April 20th "Drive your Classic Car Day"!

It's not a rehearsal

- Gopherit

- Second Gear

- Posts: 64

- Joined: 18 Oct 2007

Likewise, I'd love the drawings in PDF format! I'll pm you my address... Many thanks!

Greg

Greg

1965 Elan S2

1972 Elan +2S 130

1972 Elan +2S 130

- ElanSeries2

- Second Gear

- Posts: 81

- Joined: 06 Nov 2007

I made a similar suspension bush puller back in '78 (when my lathe was working).

I made it from a chunk of 3 inch square steel bar. I made a circular depression in it just longer than a bush. Then a threaded cylindical plug just a few thou narrower than a bush.

I didn't bother to make the outer part cylindrical.

It works fine & I've used it a number of times, including when a dumb MOT inspector thought my bushes were worn out... They were not...

I made it from a chunk of 3 inch square steel bar. I made a circular depression in it just longer than a bush. Then a threaded cylindical plug just a few thou narrower than a bush.

I didn't bother to make the outer part cylindrical.

It works fine & I've used it a number of times, including when a dumb MOT inspector thought my bushes were worn out... They were not...

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Here are photos of the bush extractor that I mentioned above. I made it years ago when I had a working lathe. The difficult bit was sawing through that whole square bar to make the outer; I used just a hand hacksaw; it took ages !!  It looks a bit brassy in these photos but in fact is all mild steel.

It looks a bit brassy in these photos but in fact is all mild steel.

There are no plans as the diameter of the plug and bore and length of the cavity can be measured on the suspension arms. The two smaller holes in the square block are threaded so that bolts can be screwed down in them to push the extracted bush out of the bore.

Note the small inset on one end of the plug and small protrusion on the other end; these fit the external steel case of the bush. The strong threaded centre rod is long enough to go through the Square block, through the suspension hole, through a new bush and well into the plug so that it can pull the bush into the suspension arm. But several different length bolts or threaded bars can be used instead.

There are no plans as the diameter of the plug and bore and length of the cavity can be measured on the suspension arms. The two smaller holes in the square block are threaded so that bolts can be screwed down in them to push the extracted bush out of the bore.

Note the small inset on one end of the plug and small protrusion on the other end; these fit the external steel case of the bush. The strong threaded centre rod is long enough to go through the Square block, through the suspension hole, through a new bush and well into the plug so that it can pull the bush into the suspension arm. But several different length bolts or threaded bars can be used instead.

- Attachments

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

11 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 4 guests