AKS water Pump Module Strip?

62 posts

• Page 1 of 5 • 1, 2, 3, 4, 5

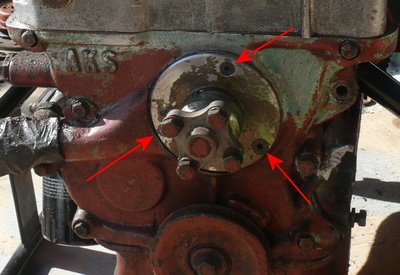

attachment=1]image.jpg[/attachment]I need to rebuild my AKS pump module, does anyone know how to strip it?

Both impeller and pulley wheel at either end j seem to be pressed onto the bearing shaft, although I've managed to carefully remove the pulley wheel steel mount, which was a loose interference fit, and came off readily.

The issue is in trying to remove the pressed steel impeller, ( it is not cast like the original Lotus component), it seems to have been punch fitted onto the shaft, and the only apparent leverage point seems to be the gap between the impeller and the alloy boss - however, I'm obviously scared to lever here and possibly damage the alloy boss.

There's no lock wire clip either, so how's it held in place?

Reading the Forums it's suggested that the components may have come from the SOHC Sierra / Pinto water pump, but this one looks like a standard TC water pump bearing / shaft?

It does have a rubber boot or grommet on the shaft inside the Module Boss, but I can't see what's inside, to see if there's a clip there?

Any helpful advice would be appreciated, or if anyone has a spare module .......?

Thanks,

Phil.

Both impeller and pulley wheel at either end j seem to be pressed onto the bearing shaft, although I've managed to carefully remove the pulley wheel steel mount, which was a loose interference fit, and came off readily.

The issue is in trying to remove the pressed steel impeller, ( it is not cast like the original Lotus component), it seems to have been punch fitted onto the shaft, and the only apparent leverage point seems to be the gap between the impeller and the alloy boss - however, I'm obviously scared to lever here and possibly damage the alloy boss.

There's no lock wire clip either, so how's it held in place?

Reading the Forums it's suggested that the components may have come from the SOHC Sierra / Pinto water pump, but this one looks like a standard TC water pump bearing / shaft?

It does have a rubber boot or grommet on the shaft inside the Module Boss, but I can't see what's inside, to see if there's a clip there?

Any helpful advice would be appreciated, or if anyone has a spare module .......?

Thanks,

Phil.

Last edited by l10tus on Mon Jul 15, 2013 12:10 am, edited 2 times in total.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

Probably the bearing is a press fit in the housing and you will need to press it out to the rear, by using a tube which is just less than the outer of the bearing.

Once you have the shaft out with bearing and impellor you should be able to press the shaft out of the impellor by supporting it with a tube which is a sliding fit over the bearing.

The rubber boot or grommet that you mention must be the all important water seal.

Once you have the shaft out with bearing and impellor you should be able to press the shaft out of the impellor by supporting it with a tube which is a sliding fit over the bearing.

The rubber boot or grommet that you mention must be the all important water seal.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Bill,

Thanks for the reply, you have a similar idea as me, in thinking the bearing will press out, but I didn't want to try - in fear of damaging the Module ?

Have you had experience doing this with one of these before?

I appreciate your thoughts !

Regards,

Phil.

Thanks for the reply, you have a similar idea as me, in thinking the bearing will press out, but I didn't want to try - in fear of damaging the Module ?

Have you had experience doing this with one of these before?

I appreciate your thoughts !

Regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

l10tus wrote:Bill,

Thanks for the reply, you have a similar idea as me, in thinking the bearing will press out, but I didn't want to try - in fear of damaging the Module ?

Have you had experience doing this with one of these before?

I appreciate your thoughts !

Regards,

Phil.

I have done the standard Lotus waterpump a number of times and the Burton Module pump once. In each case you push the bearing out from the front so that it comes out of the rear, after removing the pulley holder. They do have a slightly looser fit though than what you seem to have, and they have the semi-ring thing to prevent movement. (not that they would move anyway, because the standard one is a pretty tight fit.

You might want to heat the module a bit while pressing.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Phil

I've had one of these for years (2004)and have been on the lookout for a spare capsule for the same length of time,have even been in touch with the "Manufacturer" but to no avail, have a block of Ali. in the shed for the past few years intending to turn a spare but have never got round to it.....maybe this winter....

John

I've had one of these for years (2004)and have been on the lookout for a spare capsule for the same length of time,have even been in touch with the "Manufacturer" but to no avail, have a block of Ali. in the shed for the past few years intending to turn a spare but have never got round to it.....maybe this winter....

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

I have rebuilt a few similar modules but not specifically a AKS one.

You support the alloy housing and press the bearing and impeller out to the rear once you have pulled the front pulley mounting hub. The impeller can then be pulled off the old bearing if you want to recover it for reuse. The pressed metal style impellor show in the picture is hard to remove as you need to get a bearing splitter in between the seal and the impeller and pull on the impellor hub as you cant pull on the rim. With the cast impellors you can use a conventional puller on the rim if your careful

You need to be carful how much load you apply always when pulling press assembled components and heating the alloy housing and impellor gently will help if excessive force is needed to remove.

On reassembly you need to locate the bearing in the housing correctly so you can then assemble the impellor on the shaft and get the correct compression on the seal. Without specific instruction on the module you have and the seal you have and the impellor you have for reassembly all of which can vary in dimensions you need to figure out the correct assembly dimensions yourself !

cheers

Rohan

You support the alloy housing and press the bearing and impeller out to the rear once you have pulled the front pulley mounting hub. The impeller can then be pulled off the old bearing if you want to recover it for reuse. The pressed metal style impellor show in the picture is hard to remove as you need to get a bearing splitter in between the seal and the impeller and pull on the impellor hub as you cant pull on the rim. With the cast impellors you can use a conventional puller on the rim if your careful

You need to be carful how much load you apply always when pulling press assembled components and heating the alloy housing and impellor gently will help if excessive force is needed to remove.

On reassembly you need to locate the bearing in the housing correctly so you can then assemble the impellor on the shaft and get the correct compression on the seal. Without specific instruction on the module you have and the seal you have and the impellor you have for reassembly all of which can vary in dimensions you need to figure out the correct assembly dimensions yourself !

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8410

- Joined: 22 Sep 2003

Gents,

Thanks for all the detailed replies - much appreciated.

General consensus of opinion is to press it out then?

I have a small 20 tonne hydraulic bench press, so here goes!

I'll feedback any results or issues, to the group ASAP.

Great Forum help as usual!

Best regards,

Phil.

Thanks for all the detailed replies - much appreciated.

General consensus of opinion is to press it out then?

I have a small 20 tonne hydraulic bench press, so here goes!

I'll feedback any results or issues, to the group ASAP.

Great Forum help as usual!

Best regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

I have an engine with an AKS water pump fitted.

But I have a problem - a PO has totally mangled the Allen key heads of the 3 countersunk screws holding the pump module to the timing cover.

Consequently I haven't as yet been able to remove the pump from the cover.

Having never seen the back of an AKS timing cover or an AKS back plate, I am hoping that somebody might be able to tell me if the 3 screws which attach the pump module pass through the timing cover into the AKS back plate or do they just screw into the timing cover?

I suspect (unfortunately) that they do screw into the back plate for the simple reason that I have the head, crank pulley and sump removed and all the other visible timing case bolts yet I am still unable to remove the timing cover.

But I have a problem - a PO has totally mangled the Allen key heads of the 3 countersunk screws holding the pump module to the timing cover.

Consequently I haven't as yet been able to remove the pump from the cover.

Having never seen the back of an AKS timing cover or an AKS back plate, I am hoping that somebody might be able to tell me if the 3 screws which attach the pump module pass through the timing cover into the AKS back plate or do they just screw into the timing cover?

I suspect (unfortunately) that they do screw into the back plate for the simple reason that I have the head, crank pulley and sump removed and all the other visible timing case bolts yet I am still unable to remove the timing cover.

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

AlfaLofa wrote:I suspect (unfortunately) that they do screw into the back plate for the simple reason that I have the head, crank pulley and sump removed and all the other visible timing case bolts yet I am still unable to remove the timing cover.

No they screw into the block - They are clearance in the front cover and the backplate. As with the standard set-up the front cover must be removed before you can get to the separate bolt that retains the backplate.

- AHM

- Coveted Fifth Gear

- Posts: 1258

- Joined: 19 Apr 2004

Hi AHM,

You are right they do go into the block.

Replenished by a corn beef sandwich I have just been able to remove one of the bolts.

To drill and tap the block for the AKS water pump kit was beyond what I was expecting.

I don't know what to do about the remaining pair of bolts though - the heads are totally butchered.

I may have to remove part of the pump flange from around the bolts and then hopefully remove the pump module.

I might then be able to get some mole grips on the bolts and get them out.

Failing that I may have to resort to the grinder to remove the cover/back plate assembly.

If I can get the bolts out after removing some of the metal from the pump flange I'll either get 3 new holes drilled or get a new flange made up.

You are right they do go into the block.

Replenished by a corn beef sandwich I have just been able to remove one of the bolts.

To drill and tap the block for the AKS water pump kit was beyond what I was expecting.

I don't know what to do about the remaining pair of bolts though - the heads are totally butchered.

I may have to remove part of the pump flange from around the bolts and then hopefully remove the pump module.

I might then be able to get some mole grips on the bolts and get them out.

Failing that I may have to resort to the grinder to remove the cover/back plate assembly.

If I can get the bolts out after removing some of the metal from the pump flange I'll either get 3 new holes drilled or get a new flange made up.

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

The holes in the block are already there and threaded; They held the external waterpump on the push-rod Ford 108E engine. Lotus simply used the same holes for the original timing case and the after-market module pumps cases are also designed to use them.

The bolts are probably a bit too thin and hard to be able to reliably drill into the centre of the hex and use a stud extractor, but I would probably try that first.

As a last resort, you could drill the heads off the hex bolts turning them into headless studs, then you should then be able to pull the AKS pump module. If there is not enough biolt/stud poking out to use a mole wrench then remove the bolts around the edge of the timing case and the upwards bolts from the sump. You and gently pry off the front of the timing case.

When the bolts (now studs) are exposed you should be able to unscrew them with a mole wrench.

Get new bolts and reassemble. Thin smear of silicone goo between the surfaces on re-assemble, you do not want blobs of silicone rubber wandering around in your engine oil system.

The bolts are probably a bit too thin and hard to be able to reliably drill into the centre of the hex and use a stud extractor, but I would probably try that first.

As a last resort, you could drill the heads off the hex bolts turning them into headless studs, then you should then be able to pull the AKS pump module. If there is not enough biolt/stud poking out to use a mole wrench then remove the bolts around the edge of the timing case and the upwards bolts from the sump. You and gently pry off the front of the timing case.

When the bolts (now studs) are exposed you should be able to unscrew them with a mole wrench.

Get new bolts and reassemble. Thin smear of silicone goo between the surfaces on re-assemble, you do not want blobs of silicone rubber wandering around in your engine oil system.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Thanks for that Bill - I was too daft to think that the holes were already in the block

The trouble is that the AKS module is held by countersunk screws - so they are flush with the flange with no bolt heads to grip with moles.

I'm now searching ebay for a suitable Dremel cutting disc to see if cut a suitable slot for a screw driver. I'll be happy with a bit of collateral damage to the flange if I can get the screws out!

The screws are very black steel - does this mean they are hardened??

The trouble is that the AKS module is held by countersunk screws - so they are flush with the flange with no bolt heads to grip with moles.

I'm now searching ebay for a suitable Dremel cutting disc to see if cut a suitable slot for a screw driver. I'll be happy with a bit of collateral damage to the flange if I can get the screws out!

The screws are very black steel - does this mean they are hardened??

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

From the photo I see that your cylinder head is still on, which makes removal of the front of the timing case more difficult, though it can be done. You need to take out the bolts upwards into the head and the long bolt (inside the cam cover) that clamps the front case to the head.

Then you need to lower the sump an inch or so, so that you can pull the front on the timing case forward.

It's tricky, but I've done it before (on a camp-site) to replace a standard non-modular water pump.

On replacing the case you need to used sliced off portions of the case to head gasket and the sump gaskets. with silicone to fill any gaps.

~~~~

A heck of a lot of effort all because of a careless PO.

~~~~~

I've never been sure whether the black surface of hex head bolts means they are hardened, I thought so, but if that was the case it's hard to see why a badly fitting hex key smeared the holes.

Then you need to lower the sump an inch or so, so that you can pull the front on the timing case forward.

It's tricky, but I've done it before (on a camp-site) to replace a standard non-modular water pump.

On replacing the case you need to used sliced off portions of the case to head gasket and the sump gaskets. with silicone to fill any gaps.

~~~~

A heck of a lot of effort all because of a careless PO.

~~~~~

I've never been sure whether the black surface of hex head bolts means they are hardened, I thought so, but if that was the case it's hard to see why a badly fitting hex key smeared the holes.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Bill - sorry that's an old photo - everything has been removed (head, sump, crank pulley).

Correction - everything has been removed except the remaining 2 module bolts

Correction - everything has been removed except the remaining 2 module bolts

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

62 posts

• Page 1 of 5 • 1, 2, 3, 4, 5

Total Online:

Users browsing this forum: No registered users and 12 guests