clutch release bearing attachment

13 posts

• Page 1 of 1

Following the completion of a re-build, I intended to fit the engine back into the car today. However I have spent the afternoon and evening frustrated by the release bearing!!

No matter which way I try, I cannot satisfactorily fix the arm to the bearing carrier with the two springs. I have studied the manuals intently and am satisfied the springs are the correct spec. but they simply don't hold the carrier under tension and fall off when fitted the gearbox mainshaft with the arm on the bellhousing pivot. The mechanism was working fine prior to removal.

Having sat with the parts on the kitchen table for the past two hours, I have tried more moves than a Rubik's cube but without any joy. Am I missing an obvious trick here? Any suggestions would be greatly appreciated.

Bob

No matter which way I try, I cannot satisfactorily fix the arm to the bearing carrier with the two springs. I have studied the manuals intently and am satisfied the springs are the correct spec. but they simply don't hold the carrier under tension and fall off when fitted the gearbox mainshaft with the arm on the bellhousing pivot. The mechanism was working fine prior to removal.

Having sat with the parts on the kitchen table for the past two hours, I have tried more moves than a Rubik's cube but without any joy. Am I missing an obvious trick here? Any suggestions would be greatly appreciated.

Bob

- bobashton

- First Gear

- Posts: 20

- Joined: 15 Nov 2003

Bob

If you're round the SK13 2NX postcode,give me a pm and I'll come and show/do it for you..

John

If you're round the SK13 2NX postcode,give me a pm and I'll come and show/do it for you..

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4522

- Joined: 21 Sep 2003

No problem

Saturday 12:00 at the car?

John

Saturday 12:00 at the car?

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4522

- Joined: 21 Sep 2003

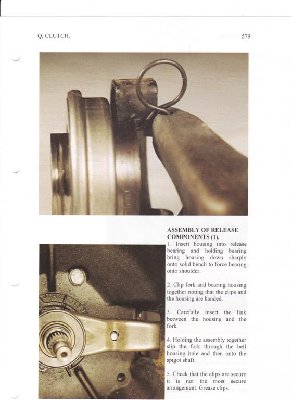

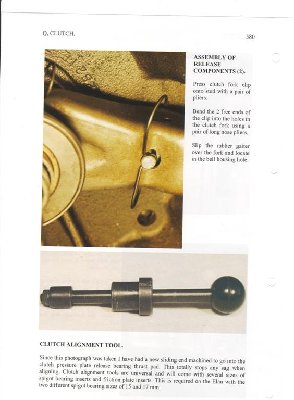

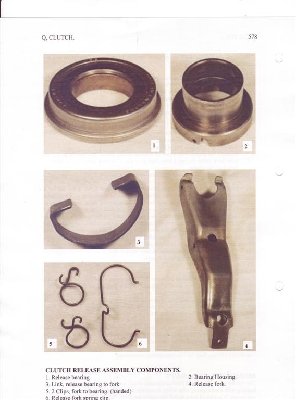

Hard to explain over the internet but study the pics in the workshop manual and you should not have a problem, note the two retaining springs are handed. Pics from the B.B.book.

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3404

- Joined: 11 Sep 2003

Brian,

Thanks for the attachment, it has been very helpful in that I have tried that method of attachment but found it insecure. Therefore, it must be that the springs have become deformed or lost their elasticity, I simply overlooked these as 'consumables' when drawing up my rebuild shopping list.

The Buckland book looks absolutely awesome compared to the Lotus workshop manual and probably would have svaed me an entire weekend. This experience has made me realise that the book is an essential and will be first on my list for Donnington next weekend.

Thanks again.

Bob

Thanks for the attachment, it has been very helpful in that I have tried that method of attachment but found it insecure. Therefore, it must be that the springs have become deformed or lost their elasticity, I simply overlooked these as 'consumables' when drawing up my rebuild shopping list.

The Buckland book looks absolutely awesome compared to the Lotus workshop manual and probably would have svaed me an entire weekend. This experience has made me realise that the book is an essential and will be first on my list for Donnington next weekend.

Thanks again.

Bob

- bobashton

- First Gear

- Posts: 20

- Joined: 15 Nov 2003

Last year- two weeks before I set off for the Le Mans Classics (!) my clutch release fork failed, it split into two pieces with the failure line between the spring holes.

Got a new fork and bits from Matty (btw, the new fork is much stronger than the old standard pressed part, being thicker gauge material and welded rather than stamped out). I had the very devil of a job trying to get the new "big" spring to go back into place' when I eventually compared it to the old one I found that the little straight bits on the ends (see Brian's photo) were just a bit longer. 2 sec on the bench grinder and it all went together!

Good luck.

Pete.

Got a new fork and bits from Matty (btw, the new fork is much stronger than the old standard pressed part, being thicker gauge material and welded rather than stamped out). I had the very devil of a job trying to get the new "big" spring to go back into place' when I eventually compared it to the old one I found that the little straight bits on the ends (see Brian's photo) were just a bit longer. 2 sec on the bench grinder and it all went together!

Good luck.

Pete.

-

elansprint71 - Coveted Fifth Gear

- Posts: 2625

- Joined: 16 Sep 2003

Thanks for the replies and suggestions, I took John Clegg up on his kind offer and popped round to compare my springs to some new ones he happened to have. It was obvious that mine had become distorted and would not hold the bearing carrier. Athough we have sucessfully adjusted them, they are a nominal cost and so I ordered a pair from Matty's today. I hadn't considered the fork though  but at ?65 +vat I'll take a risk.

but at ?65 +vat I'll take a risk.

Thanks again to John and all contributors, this really demonstrates the true worth of this forum.

Bob

Thanks again to John and all contributors, this really demonstrates the true worth of this forum.

Bob

- bobashton

- First Gear

- Posts: 20

- Joined: 15 Nov 2003

That whole set-up is not very confidence-inspiring, is it? Especially considering the implications if any of those flimsy parts are installed incorrectly or fail...

The job is made worse when you do it with the engine pulled out but the transmission is still in the car. And you are working on your back on a creeper, with poor lighting. All of which makes logical thinking a little difficult

Carlos G

The job is made worse when you do it with the engine pulled out but the transmission is still in the car. And you are working on your back on a creeper, with poor lighting. All of which makes logical thinking a little difficult

Carlos G

- cbguerrajr

- Second Gear

- Posts: 62

- Joined: 04 Nov 2004

.....new springs are fundamental! and once it's put together properly you do get the feeling it's just not tight enough (too fiddly!) BUT it works even if you have littlte faith in this solution. A N D keep an eye on the clearance (slave cylinder) fork : bearingholder (1,5mm?) - i check it at least 5 times as it sort needs embedding and/or changes!! sandy

- el-saturn

- Coveted Fifth Gear

- Posts: 1031

- Joined: 27 Jun 2012

I have the same issue , except my clutch cover does not have the thrust pad so I'm using the burton spacer and round bearing. Does the picture below look right , both my springs are the same hand.

- Concrete-crusher

- Third Gear

- Posts: 380

- Joined: 09 Jun 2013

13 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 0 guests