Headlight Wiring

25 posts

• Page 1 of 2 • 1, 2

Whilst I have a mass of spaghetti in the engine bay and my refurbished dashboard is all wired up, I was wondering if anyone has simplified their headlight wiring - Its a late 68 Plus 2 (non federal).

I have fitted MX5 pod motors and want to combine their use with the headlights. I know I can raise these by using a simple relay - no problem, but is it a simple case of taking a live from the headlight switch (dip beam) as the up control with another fused live as the constant lower control?

I would also like to simplify the headlight and full beam circuits, do I really need all these relays, micro switches and wires

All idiot drawings and diagrams would be gratefully appreciated because although I know I can rewire this car, my electrical skills are moderate, my theory skills are not!

Thanks in advance,

Kev.

I have fitted MX5 pod motors and want to combine their use with the headlights. I know I can raise these by using a simple relay - no problem, but is it a simple case of taking a live from the headlight switch (dip beam) as the up control with another fused live as the constant lower control?

I would also like to simplify the headlight and full beam circuits, do I really need all these relays, micro switches and wires

All idiot drawings and diagrams would be gratefully appreciated because although I know I can rewire this car, my electrical skills are moderate, my theory skills are not!

Thanks in advance,

Kev.

- KevJ+2

- Fourth Gear

- Posts: 641

- Joined: 23 Aug 2013

I used two 'double make and break' relays for the headlamp power, one for high ('main') beam and one for low ('dipped') beam. I fused each headlamp filament separately, but the double contact relay simplifies things a bit. I also ran a headlight / sidelight loom leg on each side of the car rather than the stock configuration with one driver's side leg and wires routed through the cowl ahead of the radiator.

I only needed one changeover relay to control the pod motor. Mine is a Federal car, so only one motor is required; I think you require one motor & relay per side. The Federal microswitches, located at the dash switch, have a Normally Closed contact set which is used to control the pod lowering; you may require one more relay if you don't have a NC contact set available. I didn't use a 'Flash to Pass' or separate pod raising controller as not sure if my Toyota donor car had one; the dash light switch raises and lowers the pods and 'Flash to Pass' from the column stock is run through a couple of aftermarket driving lights and a separate relay..

To avoid a lot of spaghetti to the engine bay I mounted all the fuses and most of the relays on the main glovebox wall. I really like this configuration because all the low current relay trigger wires are contained on the dash. Other advantage is all the fuses and relays stay clean and dry. Disadvantage is it is a tight fit in the Plus 2 because of the vent hose routing, so the wiring on the back of the fuse / relay boxes as to be carefully done to fit, and the glovebox has to be cut..

I used several modern multi-connector plugs to make dash removal relatively easy, at least from a wiring perspective. I think the only relay that ended up in the engine bay was for the electric fan; I ran out of slots in the glovebox and the fan temperature controller is right there anyway so that one made sense. i think I mounted a couple of radio related relays in the trunk.

Not sure of your 'Non Federal' switches, but the Federal flat rockers really benefit from using relays, so yes, I really think they are the way to go even with the extra wiring complexity.

HTH

Stu

I only needed one changeover relay to control the pod motor. Mine is a Federal car, so only one motor is required; I think you require one motor & relay per side. The Federal microswitches, located at the dash switch, have a Normally Closed contact set which is used to control the pod lowering; you may require one more relay if you don't have a NC contact set available. I didn't use a 'Flash to Pass' or separate pod raising controller as not sure if my Toyota donor car had one; the dash light switch raises and lowers the pods and 'Flash to Pass' from the column stock is run through a couple of aftermarket driving lights and a separate relay..

To avoid a lot of spaghetti to the engine bay I mounted all the fuses and most of the relays on the main glovebox wall. I really like this configuration because all the low current relay trigger wires are contained on the dash. Other advantage is all the fuses and relays stay clean and dry. Disadvantage is it is a tight fit in the Plus 2 because of the vent hose routing, so the wiring on the back of the fuse / relay boxes as to be carefully done to fit, and the glovebox has to be cut..

I used several modern multi-connector plugs to make dash removal relatively easy, at least from a wiring perspective. I think the only relay that ended up in the engine bay was for the electric fan; I ran out of slots in the glovebox and the fan temperature controller is right there anyway so that one made sense. i think I mounted a couple of radio related relays in the trunk.

Not sure of your 'Non Federal' switches, but the Federal flat rockers really benefit from using relays, so yes, I really think they are the way to go even with the extra wiring complexity.

HTH

Stu

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1944

- Joined: 03 Sep 2007

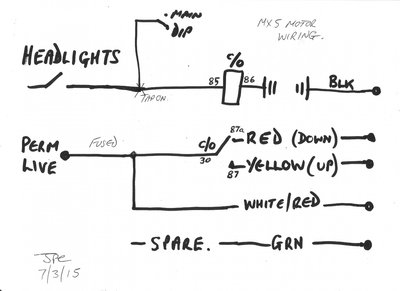

Something like this....

edited for fuse and relay numbers

John

edited for fuse and relay numbers

John

Last edited by john.p.clegg on Sat Mar 07, 2015 5:00 pm, edited 2 times in total.

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

Quick couple of adders while I am on a roll...

I used the British dedicated wire colours throughout the loom. I can keep the relay trigger wires and load wires straight on a lot of the circuits because I generally used different wire gauges in the same colours.

For the headlight pod motors i used various colours in the Orange / Trace Colour series as the devises are not used in the Elan, or in the case of the wipers they use different (older?) colour conventions..

http://www.autoelectricsupplies.co.uk/c ... rder_2.pdf

As the wiring ends up significantly different from stock, I documented each functional circuit on separate 11 x 17 cardstock diagrams. My BMW Electrical Trouble Shooting Manual follows a similar format. I don't have the drafting skills and patience to attempt to put the whole car on a single page, and frankly after spending a bunch of hours trying to read the various Plus 2 Workshop Manual diagrams I thought splitting things up made sense. Minor disadvantage of this format is you have to put notes referencing different diagrams, and you require a fuse and relay list and a loom layout & dash layout diagram to keep things straight.

I had never done a project like this and managed to get through it over a winter. Really glad I did the rewire myself as there are so many different approaches to take at least I know my car thoroughly. Hopefully not to bad for a next owner, but who knows.

HTH

Stu

I used the British dedicated wire colours throughout the loom. I can keep the relay trigger wires and load wires straight on a lot of the circuits because I generally used different wire gauges in the same colours.

For the headlight pod motors i used various colours in the Orange / Trace Colour series as the devises are not used in the Elan, or in the case of the wipers they use different (older?) colour conventions..

http://www.autoelectricsupplies.co.uk/c ... rder_2.pdf

As the wiring ends up significantly different from stock, I documented each functional circuit on separate 11 x 17 cardstock diagrams. My BMW Electrical Trouble Shooting Manual follows a similar format. I don't have the drafting skills and patience to attempt to put the whole car on a single page, and frankly after spending a bunch of hours trying to read the various Plus 2 Workshop Manual diagrams I thought splitting things up made sense. Minor disadvantage of this format is you have to put notes referencing different diagrams, and you require a fuse and relay list and a loom layout & dash layout diagram to keep things straight.

I had never done a project like this and managed to get through it over a winter. Really glad I did the rewire myself as there are so many different approaches to take at least I know my car thoroughly. Hopefully not to bad for a next owner, but who knows.

HTH

Stu

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1944

- Joined: 03 Sep 2007

Thanks Stu & John for your speedy replies!

Stu - wow that's a lot of info Does this mean I can bypass the 6RA flasher, I'm assuming this gives the flash to pass? Are the other relays on the wheel arch power to lights relays (I know the red one is the horn relay).

Does this mean I can bypass the 6RA flasher, I'm assuming this gives the flash to pass? Are the other relays on the wheel arch power to lights relays (I know the red one is the horn relay).

I have tried my hardest to absorb my blown up wiring diagram, and although I understand about 90% of it, the lighting circuit is a bit of a mystery. The relays and micro switch system is overly complicated and as I understand - wrong on the diagram.

Should I assume that the lighting switch controls the changeover relays with power to the lights taken from a fused source through the relay? and the main beam the same system?

Sorry to be a bit thick on this but if I can get beyond this hurdle, I think I can get my head around the rest.

All the best,

Kev.

Stu - wow that's a lot of info

I have tried my hardest to absorb my blown up wiring diagram, and although I understand about 90% of it, the lighting circuit is a bit of a mystery. The relays and micro switch system is overly complicated and as I understand - wrong on the diagram.

Should I assume that the lighting switch controls the changeover relays with power to the lights taken from a fused source through the relay? and the main beam the same system?

Sorry to be a bit thick on this but if I can get beyond this hurdle, I think I can get my head around the rest.

All the best,

Kev.

- KevJ+2

- Fourth Gear

- Posts: 641

- Joined: 23 Aug 2013

KevJ+2 wrote:Should I assume that the lighting switch controls the changeover relays with power to the lights taken from a fused source through the relay? and the main beam the same system?

Sorry to be a bit thick on this but if I can get beyond this hurdle, I think I can get my head around the rest.

All the best,

Kev.

Kev

If you're talking to me re. the diagram, no, the power to switch the relay is tapped into the headlight feed to the main/dip switch. Power to the lights is unchanged.

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

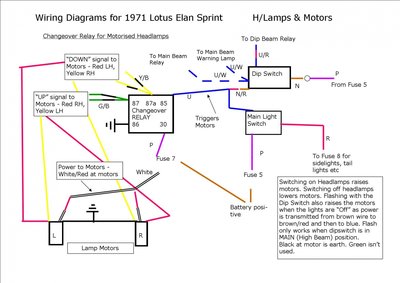

Kev, I apologise for the attached diagram - it looks more complicated than it really is. I have extensively modified the electrics on my Sprint and have 12 spade fuses and lots of relays, including one for the main beam, one for the dip beam and a changeover relay for the motors as described by Stu and John. The beauty of the changeover relay is that applying power to terminal 85 makes it connect 87 to power, and removing the power from 85 causes it to connect 87a to power, so these can be used to feed current to the UP and DOWN side of the motors.

If you look carefully at my diagram you will note that the two motors are connected opposite to each other. This is simply because the way I mounted them I needed one to turn clockwise and the other to turn anti-clockwise. You could connect them whichever way round suits your installation.

This installation works a treat. Switching the main light switch to the headlight position activates the motors and sends power to the dip switch. You don't need any of the original relays or micro-switches. The lamps rise very smartly and are firm once up, without need of any stops.

The only downside which I have been unable to solve is that the daytime flash facility can only work if the dip switch is left in the main beam position. In the dip position the flash control does nothing.

I hope you can make sense of the diagram!

Mike

If you look carefully at my diagram you will note that the two motors are connected opposite to each other. This is simply because the way I mounted them I needed one to turn clockwise and the other to turn anti-clockwise. You could connect them whichever way round suits your installation.

This installation works a treat. Switching the main light switch to the headlight position activates the motors and sends power to the dip switch. You don't need any of the original relays or micro-switches. The lamps rise very smartly and are firm once up, without need of any stops.

The only downside which I have been unable to solve is that the daytime flash facility can only work if the dip switch is left in the main beam position. In the dip position the flash control does nothing.

I hope you can make sense of the diagram!

Mike

-

TroonSprint - Fourth Gear

- Posts: 507

- Joined: 24 Nov 2011

Here's a wiring diagram to include daytime flashing. A second motor can be wired in parallel.

Dougal.

Dougal.

- dougal9887

- Third Gear

- Posts: 244

- Joined: 23 Aug 2013

John, thanks again, I think the tap you mean is shown in Mike's diagram.

Mike, thanks very much for the diagram and yes, it does make sense. I take it that when you can't flash unless in the main beam position, you have to flash by switching on the main light switch with the stalk on full beam?

As I see it, all the old relays are removed, does this include the 6RA behind the dash and if so, how? I too have to turn the yellow and reds around on the motors as I fitted them with both drive facing inwards.

Dougal, your diagrams are very impressive, but without colours and numbers, I think it would be too much for me to take on

Best regards,

Kev.

Mike, thanks very much for the diagram and yes, it does make sense. I take it that when you can't flash unless in the main beam position, you have to flash by switching on the main light switch with the stalk on full beam?

As I see it, all the old relays are removed, does this include the 6RA behind the dash and if so, how? I too have to turn the yellow and reds around on the motors as I fitted them with both drive facing inwards.

Dougal, your diagrams are very impressive, but without colours and numbers, I think it would be too much for me to take on

Best regards,

Kev.

- KevJ+2

- Fourth Gear

- Posts: 641

- Joined: 23 Aug 2013

No Kev, you can flash the headlights in the daytime without touching the main light switch. You just simply pull on the dip switch lever, but only if it is in the main beam position. If it is sitting in the dip position the circuit isn't made - it's a function of the way the dip/flash switch works.

When the switch is in the dip position, the main light switch is off and you pull the flash lever, power for the lights comes into the dip switch from my Fuse 5 on the brown wire (extreme right of the diagram) and leaves on the blue/red to the dip filaments. So the dip filaments light but the pods don't rise because the power isn't carried onto the brown/red.

If the switch is in the main beam position and the main light switch is off, pulling the switch to the flash position causes power to leave on the blue/white to the main beam filaments, and also on the brown/red, and so to the blue, which will lift the pods.

It's no big deal. I very rarely want to flash the lights anyway.

Mike

When the switch is in the dip position, the main light switch is off and you pull the flash lever, power for the lights comes into the dip switch from my Fuse 5 on the brown wire (extreme right of the diagram) and leaves on the blue/red to the dip filaments. So the dip filaments light but the pods don't rise because the power isn't carried onto the brown/red.

If the switch is in the main beam position and the main light switch is off, pulling the switch to the flash position causes power to leave on the blue/white to the main beam filaments, and also on the brown/red, and so to the blue, which will lift the pods.

It's no big deal. I very rarely want to flash the lights anyway.

Mike

-

TroonSprint - Fourth Gear

- Posts: 507

- Joined: 24 Nov 2011

To provide daytime flash using Mike's diagram, all you require to add is a diode between the wire feeding the flashing headlight and the brown/red wire feeding the dip switch and motor relay. You would however have to hold in the flash lever whilst the pods rise so that the light is still on when they reach fully raised position. When you let go the light will extinguish and the pods will retract.

I mention 'the wire feeding the flashing headlight' since on Mike's car he describes the flash feeding dip on blue/red. On my 1972 car and in my workshop manual the flash feeds the main beam blue/white wire

These are Lotuses though so anything's possible

These are Lotuses though so anything's possible

Dougal.

I mention 'the wire feeding the flashing headlight' since on Mike's car he describes the flash feeding dip on blue/red. On my 1972 car and in my workshop manual the flash feeds the main beam blue/white wire

Dougal.

- dougal9887

- Third Gear

- Posts: 244

- Joined: 23 Aug 2013

Kev,

That is a coincidence!

I've been planning a May launch but this could slip as I broke a leg skiing end of Jan so have been somewhat disabled. However not being able to work, I've had more time to post! Also set up a sitting bench and have got on with all the small rebuild jobs, fuel and oil pumps, carbs, alternator and starter.

This is my second rebuild, having owned the car since 1977, although the body wasn't done first time around.

All good fun and I wish you well on your Lotus journey

Dougal.

That is a coincidence!

I've been planning a May launch but this could slip as I broke a leg skiing end of Jan so have been somewhat disabled. However not being able to work, I've had more time to post! Also set up a sitting bench and have got on with all the small rebuild jobs, fuel and oil pumps, carbs, alternator and starter.

This is my second rebuild, having owned the car since 1977, although the body wasn't done first time around.

All good fun and I wish you well on your Lotus journey

Dougal.

- dougal9887

- Third Gear

- Posts: 244

- Joined: 23 Aug 2013

Hmmm. You are right of course, Dougal. The headlamp flash control should always activate the main beams (blue/white). I need to check what actually happens with my Sprint. I have nearly finished the rebuild of this car that I bought entirely dismantled. If I can get the engine to run properly it can go for its first MOT in 38 years!

The wiring harness was shot, so I have built my own one, upgrading everything where necessary with a 12 position fuse box under the bonnet and a bank of relays on the side wall of the passenger footwell. I need to get the multimeter out again and see what actually happens when I pull the flash lever with the dip switch in the dipped position. I know for a fact that the pods don't activate. When the switch is in the main beam position it works as it should, although, as you say, I have to hold the lever while the pods rise. Fortunately the MX-5 motors are pretty speedy and they come up in about 1 second.

Diodes are a mystery to me (I'm a biochemist not an electrician). How would one know what type/size to buy? And where from?

Mike

The wiring harness was shot, so I have built my own one, upgrading everything where necessary with a 12 position fuse box under the bonnet and a bank of relays on the side wall of the passenger footwell. I need to get the multimeter out again and see what actually happens when I pull the flash lever with the dip switch in the dipped position. I know for a fact that the pods don't activate. When the switch is in the main beam position it works as it should, although, as you say, I have to hold the lever while the pods rise. Fortunately the MX-5 motors are pretty speedy and they come up in about 1 second.

Diodes are a mystery to me (I'm a biochemist not an electrician). How would one know what type/size to buy? And where from?

Mike

-

TroonSprint - Fourth Gear

- Posts: 507

- Joined: 24 Nov 2011

25 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 17 guests