A simple wheel protector to reduce knock-on wheel nut mishap

49 posts

• Page 1 of 4 • 1, 2, 3, 4

A Lotus owner since 1972, I too have damaged many steel and alloy road wheels with my copper hammer; achieved in the main through being so scared of missing the wheel nut/spinner that I did.

So, many years ago I made a simple wheel protector out of a flexible but impact resisting material. I chose polypropylene sheet, as for me, at that time, it was readily available.

I've been using this wheel protector now for thirty-years and more on Elans and a variety of other cars with knock-on type wheel nuts - and I haven?t hit and wheel, spoke, or my fingers in that time.

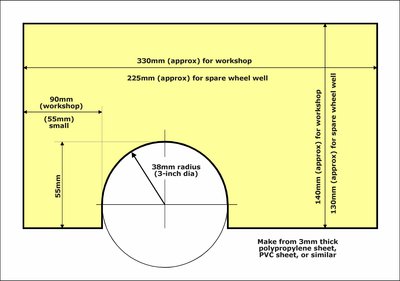

I made two; the one in the photo is stored/hung on my workshop wall and is in regular use; the second, slightly smaller, is stored in the well of my spare wheel in the boot of my Elan.

The overall dimensions of the larger workshop wheel protector are 330mm x 140mm and 225mm x 130mm for the smaller one. Make a 76mm (3") diameter cutout with straight sides to the outside of the sheet, this to enable the protector to slide over the wheel nut/spinner: see drawing and photo.

Now, I have recently shown this to others (here in the UK, and in Germany and the USA) and all think it a simple but effective tool. So make one, try it.

If it doesn't work for you then bin it. If it does, however, GREAT!

Keep it simple?

So, many years ago I made a simple wheel protector out of a flexible but impact resisting material. I chose polypropylene sheet, as for me, at that time, it was readily available.

I've been using this wheel protector now for thirty-years and more on Elans and a variety of other cars with knock-on type wheel nuts - and I haven?t hit and wheel, spoke, or my fingers in that time.

I made two; the one in the photo is stored/hung on my workshop wall and is in regular use; the second, slightly smaller, is stored in the well of my spare wheel in the boot of my Elan.

The overall dimensions of the larger workshop wheel protector are 330mm x 140mm and 225mm x 130mm for the smaller one. Make a 76mm (3") diameter cutout with straight sides to the outside of the sheet, this to enable the protector to slide over the wheel nut/spinner: see drawing and photo.

Now, I have recently shown this to others (here in the UK, and in Germany and the USA) and all think it a simple but effective tool. So make one, try it.

If it doesn't work for you then bin it. If it does, however, GREAT!

Keep it simple?

- 45bvtc

- Second Gear

- Posts: 76

- Joined: 27 Mar 2009

Hi. That looks like a Thor hammer, to save any damage to the spinners with the copper heads, replace them with hide units. I put Thor Hammers in Google and bought them from a supplier, but you will need the size of the hammer, they go in numbers like No4 etc.

Regards John.

Regards John.

The lines fall unto me in pleasant places, yea I have a goodly heritage.

- redskatejbf

- Second Gear

- Posts: 130

- Joined: 16 Nov 2006

3380 H,

I always use Sarto's superbly made spinner torque tool + 2 'taps' with a copper hammer.

I normally protect the wheels from the hammer with a piece of 6mm ply - but yours is much better.

I'll call round tomorrow to pick one up - so you have 24 hours to make it.

I always use Sarto's superbly made spinner torque tool + 2 'taps' with a copper hammer.

I normally protect the wheels from the hammer with a piece of 6mm ply - but yours is much better.

I'll call round tomorrow to pick one up - so you have 24 hours to make it.

Brian Clarke

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

-

bcmc33 - Coveted Fifth Gear

- Posts: 1708

- Joined: 10 Apr 2006

I second the use of the Sarto tool with no hammering at all. Torqued to 180 Lbs/ft, the spinners can be a bugger to get off even at that torque. I have to use a 3/4'' sq drive breaker rod about 1 Mtr long to get the spinners loose.

Those perfect new spinners will never feel a hammer. Why take the risk? Bad idea in MHO. The risk of hitting the car body, wheel, or ones self (V painful I remember) is just not an option (1..?)... I have enough to spend money on without belting the body or wheels with a hammer.. But hey, to each there own.

As I said just my humble opinion.

Alex B.....

Those perfect new spinners will never feel a hammer. Why take the risk? Bad idea in MHO. The risk of hitting the car body, wheel, or ones self (V painful I remember) is just not an option (1..?)... I have enough to spend money on without belting the body or wheels with a hammer.. But hey, to each there own.

As I said just my humble opinion.

Alex B.....

Alex Black.

Now Sprintless!!

Now Sprintless!!

-

alexblack13 - Coveted Fifth Gear

- Posts: 2072

- Joined: 17 Oct 2007

alexblack13 wrote:I second the use of the Sarto tool with no hammering at all. Torqued to 180 Lbs/ft, the spinners can be a bugger to get off even at that torque. I have to use a 3/4'' sq drive breaker rod about 1 Mtr long to get the spinners loose.

Alex B.....

I've often wondered exactly what the torque wrench equivalent of belting the spinners with a hammer was and in the spirit of scientific investigation I lashed up something similar to Sarto's tool last year. I soon found that a good whack with a hammer tightened the spinner beyond the capacity of my construction to undo - even with a 2ft breaker bar extended with some scaffolding pole. Unlike Alex I used 1/2" square drive stuff and it was the area around the end of the breaker bar that threatened to give way. Using 3/4" stuff was the logical next step but as I don't have any that's where I left it.

Going back to the earlier post by redskatejbf about using the hide side of a Thor hammer rather than the copper end, I'm a bit surprised that you can get the spinner tight enough like that. I've always used the copper end - which is why my spinners look the way they do

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

Your protector looks like a good idea

I've never really liked wheel spinners, they look good but it never feels right just thrashing away at them and never really knowing if they're tight enough or far too tight.

Anything which protects the car from hammer blows has got to be a good idea. I still use a hammer and block of hardwood which protects the spinners and moves the hammer blows a bit further away from the car but I must admit something like Sarto's tool does look like the best solution because it gets rid of the hammer and takes the guesswork out of it.

I've never really liked wheel spinners, they look good but it never feels right just thrashing away at them and never really knowing if they're tight enough or far too tight.

Anything which protects the car from hammer blows has got to be a good idea. I still use a hammer and block of hardwood which protects the spinners and moves the hammer blows a bit further away from the car but I must admit something like Sarto's tool does look like the best solution because it gets rid of the hammer and takes the guesswork out of it.

John

No longer active on here, I value my privacy.

No longer active on here, I value my privacy.

-

nebogipfel - Coveted Fifth Gear

- Posts: 1274

- Joined: 25 Sep 2003

Hello redskatejbf/John:

I hadn't given it a thought but yes, it is a THOR Copper Hammer Size 2, Ref. 04-312 (made in Shirley, Birmingham and STILL available see: http://www.thorhammer.com/Hammers/Copper/) and weighs 1.2kg, and I'll tell you now, you don't have to swing it too far, and it don't bounce.

I also have a THOR Copper Hammer Size 1, Ref. 04-310, that weights 800grams, but it's nowhere near as effective. I've cut down the stale of the Size 1 THOR to fit tightly in the boot of my Sprint - not the one shown in the photo.

Plus, they are still available new from the THOR hammer company, see|: http://www.thorhammer.com/Hammers/Coppe ... _id_04-312

Oh, and the wheels, nuts/spinners have been on since October 1998 and have done 28,000 miles and no, the nuts/spinners have not been re-chromed during that time.

And hello Alex, you are not wrong but they've always been called Knock-On or Knock-Off wheel nuts/spinners. However, I well understand your point and would not disagree? But, I used to use the Lotus supplied plate and bar spanner with octagonal nuts on my (then new) Elan +2S 130/5 and did have rear nuts come undone (usually the nearside rear) on more than one, frightening, occasion.

Also, another member who, and I've seen you banter to Brian (sorry Brian) does as you do, however, you'll remember that last year he did have a nearside rear come off (on the way back home from a Lotus meet/pub that he and I had both been to and no, he was quite sober - and a very nice man). Now Brian did have an issue with new wheels, drive pins in particular, but it was the nut that came loose first. And Brian is far from careless, I believe him when he says he properly torque-tightened his spinner.

Plus, how do you secure a weighty 3/4" drive breaker bar and fitting in the boot of a pristine Elan being driven enthusiastically around the amazing Highlands and Lowlands of my father? Please make sure the bar and/or fitting doesn't clout offside inner wall in the boot or you'll have a lovely star pattern on the outside (PM me for a photo of my star, tsk).

Regards

John

I hadn't given it a thought but yes, it is a THOR Copper Hammer Size 2, Ref. 04-312 (made in Shirley, Birmingham and STILL available see: http://www.thorhammer.com/Hammers/Copper/) and weighs 1.2kg, and I'll tell you now, you don't have to swing it too far, and it don't bounce.

I also have a THOR Copper Hammer Size 1, Ref. 04-310, that weights 800grams, but it's nowhere near as effective. I've cut down the stale of the Size 1 THOR to fit tightly in the boot of my Sprint - not the one shown in the photo.

Plus, they are still available new from the THOR hammer company, see|: http://www.thorhammer.com/Hammers/Coppe ... _id_04-312

Oh, and the wheels, nuts/spinners have been on since October 1998 and have done 28,000 miles and no, the nuts/spinners have not been re-chromed during that time.

And hello Alex, you are not wrong but they've always been called Knock-On or Knock-Off wheel nuts/spinners. However, I well understand your point and would not disagree? But, I used to use the Lotus supplied plate and bar spanner with octagonal nuts on my (then new) Elan +2S 130/5 and did have rear nuts come undone (usually the nearside rear) on more than one, frightening, occasion.

Also, another member who, and I've seen you banter to Brian (sorry Brian) does as you do, however, you'll remember that last year he did have a nearside rear come off (on the way back home from a Lotus meet/pub that he and I had both been to and no, he was quite sober - and a very nice man). Now Brian did have an issue with new wheels, drive pins in particular, but it was the nut that came loose first. And Brian is far from careless, I believe him when he says he properly torque-tightened his spinner.

Plus, how do you secure a weighty 3/4" drive breaker bar and fitting in the boot of a pristine Elan being driven enthusiastically around the amazing Highlands and Lowlands of my father? Please make sure the bar and/or fitting doesn't clout offside inner wall in the boot or you'll have a lovely star pattern on the outside (PM me for a photo of my star, tsk).

Regards

John

- 45bvtc

- Second Gear

- Posts: 76

- Joined: 27 Mar 2009

Interesting thread this...

I recall a discussion on here (somewhere) about the use of spinners (in conjunction with the spacer piece) for rear hub removal.

In this application, concerns were expressed that excessive hammering could damage the rear bearings (brinelling)

Was this concern well founded? Could it also apply to hammering spinners when fitting a wheel?

Cheers - Richard

Stop Press - Found the thread...

elan-f15/rear-hubs-off-minutes-t1561.html

"Just in general hammer blows tend to brinell damage bearings anyways. Folks really should stop using a hammer to tighten up and loosen KO nuts. Suspect the lifetime of the wheel bearing is shortened by the usage of the hammer"

I recall a discussion on here (somewhere) about the use of spinners (in conjunction with the spacer piece) for rear hub removal.

In this application, concerns were expressed that excessive hammering could damage the rear bearings (brinelling)

Was this concern well founded? Could it also apply to hammering spinners when fitting a wheel?

Cheers - Richard

Stop Press - Found the thread...

elan-f15/rear-hubs-off-minutes-t1561.html

"Just in general hammer blows tend to brinell damage bearings anyways. Folks really should stop using a hammer to tighten up and loosen KO nuts. Suspect the lifetime of the wheel bearing is shortened by the usage of the hammer"

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

3380 H wrote:Also, another member who, and I've seen you banter to Brian (sorry Brian) does as you do, however, you'll remember that last year he did have a nearside rear come off (on the way back home from a Lotus meet/pub that he and I had both been to and no, he was quite sober - and a very nice man). Now Brian did have an issue with new wheels, drive pins in particular, but it was the nut that came loose first. And Brian is far from careless, I believe him when he says he properly torque-tightened his spinner.

Thanks a lot, John, some people have long memories for remembering bad things

I thought I had tightened all the spinners before going out that evening - but you know what thought did?

The wheel did not actually come off, but the spinner did fall off in my hand when I jacked the suspension up.

I guess it must remain a fact that I could not have tightened that spinner fully in my normal practice way.

Not the same subject, but what that incident did bring home to me was that the wrong length drive pegs were fitted to suit alloy wheels. I am a lot more confident now that the rear wheels have 15mm long pegs and the fronts 10mm long pegs.

Coming back to the subject; I have two Thor hammers copper/ally and copper/nylon. The only satisfying hit is from the copper side.

Again not on the same subjet, but when I had the car on the rolling road last week I did notice how out of line the spinner ears were when looking down on them. The centre boss appeared perfectly concentric. Interesting? Maybe not.

Brian Clarke

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

-

bcmc33 - Coveted Fifth Gear

- Posts: 1708

- Joined: 10 Apr 2006

Gents

On the subject of hammers I have it on good authority that Mick Miller favoured the Dead Blow style hammers which I assume are some kind of nylon/plastic and filled with lead.

It makes sense in that it should deliver the energy yet have a cushion for the spinner surface

Unfortunately bare copper or indeed lead doesn't make much difference, they both bruise the spinners.

On the subject of hammers I have it on good authority that Mick Miller favoured the Dead Blow style hammers which I assume are some kind of nylon/plastic and filled with lead.

It makes sense in that it should deliver the energy yet have a cushion for the spinner surface

Unfortunately bare copper or indeed lead doesn't make much difference, they both bruise the spinners.

John

No longer active on here, I value my privacy.

No longer active on here, I value my privacy.

-

nebogipfel - Coveted Fifth Gear

- Posts: 1274

- Joined: 25 Sep 2003

I think some of this comes down to budget and how pristine your car is. Just read my old post. I did the unmarked new spinner thing with the new Black minlites etc and the many ?K paint job. Had homemade (3 foot long job) that kept slipping off and splitting the leather/rubber. Then the Sarto tool. Both car and tool now sold. I liked the Sarto tool but was concerned about the life of the leather and having to not take the spinner off for the first time after hammer blows. I know replacement leathers are available.

Now due to having less than perfect spinners, and car, I am happy to hammer. I have been hammering using a piece of hard wood. However, I am up for using a back shield. Sounds like a good and simple idea. Time proven.

I don?t know about this with the bearing damage (too technical for me) but have to agree that there is a certain feel that you achieve from knocking them up. The feedback from the blows is reassuring. I guess I am somewhat converted now to drive more and be sorted mechanically and worry less about the cosmetics.

One (not all) of the reasons I shifted my S4DHC on was because of trying to keep it spotless and without many marks. So much so that my wife was sick of me fretting about the car and were I parked it etc. The previous, presentable, but not ?bang on" Plus 2's did not carry this worry. Drive and enjoy.

I went to ?bolts on?s? on the track project because of the above/security and wheel choice.

PS my view for my circumstances. Also the old long tools, that I still have, do come in handy for hub exctraction as they sit on the spinner better with no wheel.

Mike

Now due to having less than perfect spinners, and car, I am happy to hammer. I have been hammering using a piece of hard wood. However, I am up for using a back shield. Sounds like a good and simple idea. Time proven.

I don?t know about this with the bearing damage (too technical for me) but have to agree that there is a certain feel that you achieve from knocking them up. The feedback from the blows is reassuring. I guess I am somewhat converted now to drive more and be sorted mechanically and worry less about the cosmetics.

One (not all) of the reasons I shifted my S4DHC on was because of trying to keep it spotless and without many marks. So much so that my wife was sick of me fretting about the car and were I parked it etc. The previous, presentable, but not ?bang on" Plus 2's did not carry this worry. Drive and enjoy.

I went to ?bolts on?s? on the track project because of the above/security and wheel choice.

PS my view for my circumstances. Also the old long tools, that I still have, do come in handy for hub exctraction as they sit on the spinner better with no wheel.

Mike

Mike

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

-

miked - Coveted Fifth Gear

- Posts: 1191

- Joined: 29 Sep 2003

49 posts

• Page 1 of 4 • 1, 2, 3, 4

Total Online:

Users browsing this forum: No registered users and 8 guests