More of the same...

13 posts

• Page 1 of 1

Hi,

Having changed the head gasket recently I finally got it back together and started the engine.

Ran ok for a bit, if a bit lumpy, then progressively got worse until it developed a missfire. Pulling the plug leads off one at a time showed very little variation in revs when I pulled no's 1 and 2 leads.

Fiddled with the carbs for a bit with no success and took the plugs out - Plugs are oily on 1 and 2 and there is a pool of oil on top of the cylinders.

Looks like the gasket has gone again

Anyone got any ideas/suggestions why this would be the case, before I take a sledghammer to it?

Having changed the head gasket recently I finally got it back together and started the engine.

Ran ok for a bit, if a bit lumpy, then progressively got worse until it developed a missfire. Pulling the plug leads off one at a time showed very little variation in revs when I pulled no's 1 and 2 leads.

Fiddled with the carbs for a bit with no success and took the plugs out - Plugs are oily on 1 and 2 and there is a pool of oil on top of the cylinders.

Looks like the gasket has gone again

Anyone got any ideas/suggestions why this would be the case, before I take a sledghammer to it?

-

Robbie693 - Coveted Fifth Gear

- Posts: 1514

- Joined: 08 Oct 2003

Before you attack it:-

Are you sure the cam & ignition timing are correct? These can make it great or a dog...

Are the valve guides worn? Oil could get into the cylinders down worn guides. I had a loose guide once which let oil leak past.

Does it pressurise the cooling system? A leak between cylinders & water passages will cause this.

What condition were the block & head faces in? If the they are not flat enough, or have scratches/scores between cylinders & oil/waterways, then it will be difficult to get a proper seal.

What type of head gasket did you use, and did you use any sealant(s)?

Has the engine been seriously overheated in the past? I believe this could lead to a 'warped' head.

Sounds like time for a compression (traditionally) or leak down (more useful I'm told) test to find out where the problem lies...

I gave up with the original engine in my +2 last year for similar but less serious reasons. The head was badly machined and possibly too soft (previous overheated perhaps) and the block had been linered by a non-specialist company I think. I changed the head gasket once (maybe twice!) and didn't get the improvement I hoped for. I didn't have time to mess about with it at that level and just wanted to use it. So I bought a QED-rebuilt Stromberg engine and fitted that instead - it's soooo much easier to work from a (hopefully!)good base...

Don't give up just yet...

Matthew

Matthew

Are you sure the cam & ignition timing are correct? These can make it great or a dog...

Are the valve guides worn? Oil could get into the cylinders down worn guides. I had a loose guide once which let oil leak past.

Does it pressurise the cooling system? A leak between cylinders & water passages will cause this.

What condition were the block & head faces in? If the they are not flat enough, or have scratches/scores between cylinders & oil/waterways, then it will be difficult to get a proper seal.

What type of head gasket did you use, and did you use any sealant(s)?

Has the engine been seriously overheated in the past? I believe this could lead to a 'warped' head.

Sounds like time for a compression (traditionally) or leak down (more useful I'm told) test to find out where the problem lies...

I gave up with the original engine in my +2 last year for similar but less serious reasons. The head was badly machined and possibly too soft (previous overheated perhaps) and the block had been linered by a non-specialist company I think. I changed the head gasket once (maybe twice!) and didn't get the improvement I hoped for. I didn't have time to mess about with it at that level and just wanted to use it. So I bought a QED-rebuilt Stromberg engine and fitted that instead - it's soooo much easier to work from a (hopefully!)good base...

Don't give up just yet...

- ppnelan

- Fourth Gear

- Posts: 691

- Joined: 16 Sep 2003

Hi Matthew,

Timing is fine - I managed to get the valve timing marks spot on, even though they were out by a tooth when I took it apart.

The guides are fine I think - there was no leakage in the ports when I had it on the bench..

I checked the head for flatness and it was less than 2 thou in the places I measured - maybe I missed a bit where it may be warped, can it warp in a small area?

Unfortunately I didn't check the block for flatness - how common is a warped block?

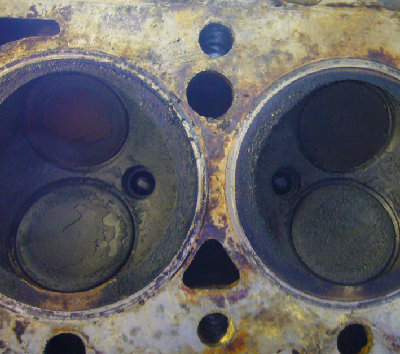

There was some slight pitting and and very fine scratches (see pics before clean up).

I used a standard gasket from Paul Matty and fitted it dry, maybe I should have used Wellseal?

There was a water leak from the back of the head before I started, this has now stopped but what I can't fathom is why the oil leakage into the cylinders is a lot worse than before..

I may have to call in the professionals

Timing is fine - I managed to get the valve timing marks spot on, even though they were out by a tooth when I took it apart.

The guides are fine I think - there was no leakage in the ports when I had it on the bench..

I checked the head for flatness and it was less than 2 thou in the places I measured - maybe I missed a bit where it may be warped, can it warp in a small area?

Unfortunately I didn't check the block for flatness - how common is a warped block?

There was some slight pitting and and very fine scratches (see pics before clean up).

I used a standard gasket from Paul Matty and fitted it dry, maybe I should have used Wellseal?

There was a water leak from the back of the head before I started, this has now stopped but what I can't fathom is why the oil leakage into the cylinders is a lot worse than before..

I may have to call in the professionals

-

Robbie693 - Coveted Fifth Gear

- Posts: 1514

- Joined: 08 Oct 2003

Fitting a standard gasket without sealant is the propable reason for the internal leakage you have, I believe.

I would take the head off again, replace the gasket with a new standard one, and use orange RTV (the high temp stuff) on both sides of the gasket. Smear on a fairly generous layer, but thin it out a bit near the oil holes. A good 0.5mm thick everywhere else.

Bolt up again and pray...

Dave Chapman.

I would take the head off again, replace the gasket with a new standard one, and use orange RTV (the high temp stuff) on both sides of the gasket. Smear on a fairly generous layer, but thin it out a bit near the oil holes. A good 0.5mm thick everywhere else.

Bolt up again and pray...

Dave Chapman.

- david.g.chapman

- Fourth Gear

- Posts: 782

- Joined: 26 Nov 2003

Thanks Dave,

I may try that, I just wondered if the sealant fix would be covering up another problem..

I spoke to an engine machining company (used by Paul Matty) and he suggested it may be the rings.

I am hoping this is not the case and the hope I'm clinging on to is that it was ok for the first half hour of running and only started to oil it's plugs when I ran it again two days later. The oil breather is not pushing out any oil either so this must be good?

I may try that, I just wondered if the sealant fix would be covering up another problem..

I spoke to an engine machining company (used by Paul Matty) and he suggested it may be the rings.

I am hoping this is not the case and the hope I'm clinging on to is that it was ok for the first half hour of running and only started to oil it's plugs when I ran it again two days later. The oil breather is not pushing out any oil either so this must be good?

-

Robbie693 - Coveted Fifth Gear

- Posts: 1514

- Joined: 08 Oct 2003

Robbie693 wrote:Timing is fine - I managed to get the valve timing marks spot on, even though they were out by a tooth when I took it apart.

Using the marks on the pulleys is not an accurate way to set the valve timing - you need a dial gauge to do it properly, as detailed in the Twin Cam Engine book by Miles Wilkins. But it will probably be near enough to run, even if it doesn't run 'perfectly'.

'The book' also details what sealants to use on the head gasket.

Try a compression or leak down test to determine what's leaking where...

It sounds like a head-off job anyway.

- ppnelan

- Fourth Gear

- Posts: 691

- Joined: 16 Sep 2003

Just a point to note, it is best to use a couple of studs or old head bolts (heads cut off) to hold the gasket in place so it doesn't move when lowering the c/head back on to the block.

I always use a red hermitite sealant on the head gasket.

Have you done a compression test yet? did you re-torqued the head again when it is cold?

I always use a red hermitite sealant on the head gasket.

Have you done a compression test yet? did you re-torqued the head again when it is cold?

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3403

- Joined: 11 Sep 2003

Just to add a couple of points:

1. check the holes in the block for the head bolts are clear of crud, otherwise one or more bolts may give a false reading.

2. assuming head and block faces are true AND that you are using the old style copper-faced head gasket with a lacquer film ......... then you should not need any sealer at all. But there is a technique for correct assembly.

I used to carry a roadside head gasket kit in the 70's, so often that mine blew. Until I met a man who told me how ! Never blew one again.

On the other hand, technology has moved on and new gaskets may be the way to go.

Regards,

Stuart.

1. check the holes in the block for the head bolts are clear of crud, otherwise one or more bolts may give a false reading.

2. assuming head and block faces are true AND that you are using the old style copper-faced head gasket with a lacquer film ......... then you should not need any sealer at all. But there is a technique for correct assembly.

I used to carry a roadside head gasket kit in the 70's, so often that mine blew. Until I met a man who told me how ! Never blew one again.

On the other hand, technology has moved on and new gaskets may be the way to go.

Regards,

Stuart.

- stuartgb100

- Fourth Gear

- Posts: 813

- Joined: 10 Sep 2005

Thanks chaps,

I don't have a compression tester and the car is running so badly now that I am reluctant to drive it anywhere..

I didn't re-torque the bolts as the Wilkins book reckons you don't have to - maybe I should try this.

I did give the head bolt hole a clean and chased the threads out, and used the locating pins for re-assembly.

Miles says use Wellseal on the gasket. I think I did this on my last plus 2 and that was fine afterwards, so I'll try again.

Got to be worth the cost of a new gasket before I go and hand the car over to Paul Matty!

I don't have a compression tester and the car is running so badly now that I am reluctant to drive it anywhere..

I didn't re-torque the bolts as the Wilkins book reckons you don't have to - maybe I should try this.

I did give the head bolt hole a clean and chased the threads out, and used the locating pins for re-assembly.

Miles says use Wellseal on the gasket. I think I did this on my last plus 2 and that was fine afterwards, so I'll try again.

Got to be worth the cost of a new gasket before I go and hand the car over to Paul Matty!

-

Robbie693 - Coveted Fifth Gear

- Posts: 1514

- Joined: 08 Oct 2003

[quote="Robbie693"]I didn't re-torque the bolts as the Wilkins book reckons you don't have to - maybe I should try this.

quote]

Does he say tighten them at 500 miles? the original Lotus manual does!

I come from the old school that DID retighten head bolts.....yes and I know many cars now have strech bolts and modern gaskets

quote]

Does he say tighten them at 500 miles? the original Lotus manual does!

I come from the old school that DID retighten head bolts.....yes and I know many cars now have strech bolts and modern gaskets

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3403

- Joined: 11 Sep 2003

Robbie693 wrote:Do you slacken and re-torque or just check the torque is correct?

Robbi, I run the engine untill it reaches operating temp,leave it to cool (at least four hours) slacken by 1/8....1/4 turn and retorque (ONE BOLT AT A TIME)

Run it untill operating temp several times (fan cutting in) leave overnight then slacken 1/8... 1/4 turn and retorque again.

Use for a month or so and then retorque again as above

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3403

- Joined: 11 Sep 2003

13 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 33 guests