Sows Ear Chassis

Continued:

I missed a couple of steps like showing when you install the small snap rings on the axle shafts but if you don't know that get someone else to do the work.

I missed a couple of steps like showing when you install the small snap rings on the axle shafts but if you don't know that get someone else to do the work.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

Hi Gary,

I know that the rear bearings are all sealed for life. But, a secondary set of metal dustshields/spacers for the rear, inner, hub bearings is called for, as per the parts book and as supplied recently when I changed my rear bearings.

Regards,

Colin.

I know that the rear bearings are all sealed for life. But, a secondary set of metal dustshields/spacers for the rear, inner, hub bearings is called for, as per the parts book and as supplied recently when I changed my rear bearings.

Regards,

Colin.

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 627

- Joined: 04 Oct 2003

fatboyoz wrote:Hi Gary,

I know that the rear bearings are all sealed for life. But, a secondary set of metal dustshields/spacers for the rear, inner, hub bearings is called for, as per the parts book and as supplied recently when I changed my rear bearings.

Regards,

Colin.

Hi Colin

You are correct in that the Issue 18 upright uses the dust shield but those didn't come along until later in the Elan production (45/7743 - 36/7762). This happened at the same time as the wider inner bearing. I stated that I was using the 6206-2RS bearings and I guess I was negligent in stating that I was doing an Issue 16 upright but I did state it was for 26/4997 so I thought I was close enough with my description, I should have been more specific I guess. Here is the Issue 18 upright and the dust shied installed, I do not believe that there is sufficient room in the issue 16 for the dust shield and I don;t believe that the drive axle is relieved for the shield either.

Gary

Friday June 1st 2:00pm

I have a set of LF14 calipers that have been rebuilt that I was going to use but they have a bit of patina on them, they have not been painted and have there original plating still on them with minor surface rust starting to bleed through. I looked at the original front calipers and though that they may come apart fairly easy so I had at them this morning. they had brand new pads and it looked to be a fresh rebuild kit installed back in 1969 or there abouts. I put some air pressure to them and the pistons moved. The first came apart easy and the next one looked like the first but was a bit more stubborn so I raised the pressure to 170 psi and tried again and one piston moved. I clamped that piston and put the air back on and nothing so I got the chisel out and hit it inside the piston with the air on and it decided to see things my way after about 15 minutes of gentle persuasion. I blasted both sets of halves and taped off the areas that I didn't want painted and then made them black.

Sunday June 3rd 05:50pm

Yesterday it rained all day so I didn't do a lot, I had gotten the engine-block for 26/4997 down from the attic earlier in the week and did nothing with it. It had been up there as a bare block for the last 15 years and it was looking a bit on the decrepit side with a fair amount of surface rust. I had bought a couple of wire wheels, one 3 inch for the bores and one 2 inch for the crank journals so Friday evening I made some rust dust just so I can get them measured and get some relatively good readings. I don't know how long its been apart, when I bought the S2 it was apart and the crankshaft was at the machine shop so I don't even remember if it had pistons. I got the crankshaft several weeks after I bought the Elan and was happy to even get it. There is no ridge on the bores so I am hoping that it will measure ok and a set of standard pistons can be used and just give it a light hone. I am usually quite hopeful and then get the real news that its about as bad as it gets. Anyway I did a bit more cleaning on it yesterday and cleaned out the rust goo in the bottom of the coolant passages. Today the rain had stopped and in between the mist and sun I did some sand blasting, I needed 2 good rear rotor for Tingles body, the Chassis that I called the two bit whore had a pair of new 20 year old rear rotors but I moved them over to 26/4997 as they are going on the better of the two chassis. that left me needing a pair so I measured the thicknesses again of the stack of 19 rotors and pulled out the 6 thickest, all of them .360 inch or better and blasted 9 sides of the 12 side, one side just looked like shit so I didn't finish the other but 4 rotors look good enough so I'll use the best two and save the other to for the next build, yes number 4 will start some time and I just need to figure out whats good and whats not. I have a new Spyder space frame that I got from Jim Gordon 8 or 9 years ago and it will be used under 36/6292 (the Ugly Flaired Coupe). I didn't take any before pictures of the rotors but they were fairly rusty, after sandblasting they look pretty good and I'll paint the centers maybe tomorrow if the weather improves.

Monday June 4th 10:00am

No painting today, we seem to be in our late March weather pattern that we skipped 2 months ago. About 50F, light winds out of the Northeast at 20 to 30 mph and the spring tides put the sandblasting area under water last night. About 10 inches of water where I was sitting blasting rotors yesterday, glad I clean up and put stuff away every time I use it.

June 12th 4:00pm

I got the rotor centers papered and painted a couple days ago, I blasted another pair of front hubs seeing I had the black paint out and they were handy and not a lot of blasting to do. Had some time off due to the fact that I really need to spend some money on parts and though I would just think about it for a bit, I am still thinking so instead of taking more time off I got on with some other stuff that could be blasted and painted. I have been thinking of the wheels that I want to use on Tingles body with the big flairs and just cant spend any money so the alternate plan is to use the 6 and 7 inch Jap Magna wheels that came with the Ugly Flaired Coupe and that meant I needed some knock-on hubs. I looked around and saw a pair of Plus2 rear hubs and that seems like a good use for them with the 7 inch Jap Magna wheels. For the fronts I found a pair of stock Elan knock-ons and blasted them, While looking for other stuff I stumbled over a pair of LF14 calipers that were out in the shed, probably the last pair that still had the pistons still in them. I cranked up the compressor to 170 PSI and had at them, took about an hour to get all 4 pistons out and blasted them too. The weather was still good so I got out masking tape and then the paint and sprayed them all. Not a lot done but one less thing to do while I get around to the inevitable of spending more money, I guess I am a couple steps closer of getting the parts for the Spyder space frame ready, nothing done is wasted, just another step on clearing the backlog of Elans so that I can get serious about the next projects that are filling up the plate...

Wednesday June 13th 8:20am

Not going to get a lot done today, more rain. I figured I would get the red/green demarcation put back on the hubs. I guess I could have just got the brush out (and I did) but I like to put the paint where it is supposed to go so I taped off the hubs again so that the mess I made was where it belonged. Lotus probably had it done with a mask but that seemed like a lot of work so paper and tape for me, I guess I have another couple of pairs to do but I would probably loose the mask if I made on before I did those so this is good enough for me.

Top photo - just taped and papered

Middle - Hunter green 90% and satin black 10% applied with a brush

Bottom - I.H. Red applied to the other pair

Seem like a lot of work to do but so is getting the hubs on the wrong side if I mess up

Friday June 15th 9:00pm

Not much done today but I found a 3/4 inch front sway bar and thought that it would be nice addition to the sows ear chassis that is going under Tingles C production body. I have a 5/8 in place currently but I think that I'll get another pair of $7 urethane bushes and install the bar. I blasted the bar and a pair of drop links, found a couple of other parts (4 bolt hub grease caps) and blasted them also. I didn't have a lot to paint but I weighed out 100 grams of satin black and used most of it. No photos (they all look the same I guess) but I got something done and the sway bar that comes off can go in the pile for the Spyder space frame.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

I'm just as likely to edit a post as to post a reply if I am the last person to post the last reply. I have said before, I am not into post counts like some here. Anyway this reply is necessary as I have some more pictures to post and 10 is the most in a reply. The last reply started almost 3 weeks ago and things have slowed down due to I don't like spending money that may be needed for real things in life but I want to keep working and making progress so I spend some when I have to and move on to other things that need to be done. Some caliper pistons arrived today and they will be going in sometime this week. I was continuing with my dashboard project that was an on the cheap thing as I had everything to do it just not the motivation to start woodworking. The motivation was I didn't feel like sandblasting and painting so the dashboard floated to the top of the list of things that needed to get done. Nearly 3 years and sometimes shit happens.

elan-f14/elan-dashboard-needed-for-pattern-t19391.html

Anyway I wanted to see how things fit so this morning I pulled back the EPDM membrane that has covered Tingles C production body for the last 7 years and looked at what needed to be done to get the dash to fit.

I figured it was going to need some work and I was right, Lotus molded the S2 body shell and then trimmed it so that it could be either LHD or RHD in the molding shop and then when an order was received then nipped off the tab that the steering column bracket wasn't bolted through so the glove box could be installed. Anyway I fitted the dashboard and marked the holes in the body that the dash bolted to and it was clear that I needed the tab glued back on and I was out of resin again.

It was pretty early so I made coffee and read the latest here and figured I would go an cut the lawn at my folks house while they were away. The 1964 Wheelhorse lawn tractor started right up, that was a good year, same year the body was molded. When I finished I went over to see Willy and borrowed a cup (well it was a pint) of resin and mat scraps while I was there to glue the tab back on. I got home about 11am and got some cardboard, wax paper and masking tape out to make the el cheep-o mold. I tore some mat to layup and then mixed up a bit resin. and did the underside of tab first.

I like fiberglass work as it gives you some time to think a bit between layups. I had some lunch and read some more internet stuff and went back out a took a photo or two.

It wasn't long before the glass hardened and I pulled away the carboard and wax paper to see what I had done. It looked ok and I ground the front to level up the front edge before I gave the front some glass

I laid up the front and gave it a few extra layers of mat as I wanted it to kick so I could finish shaping it out today. It was a bit thick in places (5/16inch) but that was near the bottom that was getting cut off anyway. more like a fat 3/16 where things were going to remain so I had enough to shape out.

I pulled out the saw-all and trimmed the tab to shape, I used the sanding block with some 80 grit to flatten the front and took a bit off the back too to get it down to the propper thickness for the steering column clamp.

not a lot done but sometimes you need an off day to just say that this stuff is not all that important. The bottom line is someething got done that needed to be and thats enough sometimes...

elan-f14/elan-dashboard-needed-for-pattern-t19391.html

Anyway I wanted to see how things fit so this morning I pulled back the EPDM membrane that has covered Tingles C production body for the last 7 years and looked at what needed to be done to get the dash to fit.

I figured it was going to need some work and I was right, Lotus molded the S2 body shell and then trimmed it so that it could be either LHD or RHD in the molding shop and then when an order was received then nipped off the tab that the steering column bracket wasn't bolted through so the glove box could be installed. Anyway I fitted the dashboard and marked the holes in the body that the dash bolted to and it was clear that I needed the tab glued back on and I was out of resin again.

It was pretty early so I made coffee and read the latest here and figured I would go an cut the lawn at my folks house while they were away. The 1964 Wheelhorse lawn tractor started right up, that was a good year, same year the body was molded. When I finished I went over to see Willy and borrowed a cup (well it was a pint) of resin and mat scraps while I was there to glue the tab back on. I got home about 11am and got some cardboard, wax paper and masking tape out to make the el cheep-o mold. I tore some mat to layup and then mixed up a bit resin. and did the underside of tab first.

I like fiberglass work as it gives you some time to think a bit between layups. I had some lunch and read some more internet stuff and went back out a took a photo or two.

It wasn't long before the glass hardened and I pulled away the carboard and wax paper to see what I had done. It looked ok and I ground the front to level up the front edge before I gave the front some glass

I laid up the front and gave it a few extra layers of mat as I wanted it to kick so I could finish shaping it out today. It was a bit thick in places (5/16inch) but that was near the bottom that was getting cut off anyway. more like a fat 3/16 where things were going to remain so I had enough to shape out.

I pulled out the saw-all and trimmed the tab to shape, I used the sanding block with some 80 grit to flatten the front and took a bit off the back too to get it down to the propper thickness for the steering column clamp.

not a lot done but sometimes you need an off day to just say that this stuff is not all that important. The bottom line is someething got done that needed to be and thats enough sometimes...

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

klfulop wrote:I don't know if I've mentioned this lately Gary, but......

YOU ROCK !!!!

Thanks for showing us that a lot of this "dirty work" can be done by people like us.

Hi Charles

Good to hear from you, hope life is going well and the Elite is safe. The "dirty work" is just part of the over all job, Its not a lot of fun to do but unless you pay some one else then thats what you buy into when you drag home a project. In my case, enough utter filth to keep me buried up to my neck for years. I do like my projects otherwise I would have gotten rid of them years ago. I was going to start a cleanup this spring and weed out the "never going to happen: stuff but got busy and they are all still here as I have been occupied trying to make them happen. All of my projects were at the end of there useful life cycle, I am getting to the end of MY useful life cycle and unless I kick it into overdrive and get on with it, these rocks tied around my ankle will surely pull me under and I refuse to let that happen.

SADLOTUS wrote:Great read and inspirational Gary, restoration and repair is better than a psychiatrist's sofa anyday.

Paul

Hi Paul

I think that was the idea of the post is to show people that in not a lot of time or with a lot of money you can do a lot of the work to get those "dreams" of yesterday kick started. Looking at stuff doesn't get it done, I have been looking at this stuff for several years, well maybe a bit longer than several. Anyway like most stuff its about doing a little bit every day as thats really how shit gets done.

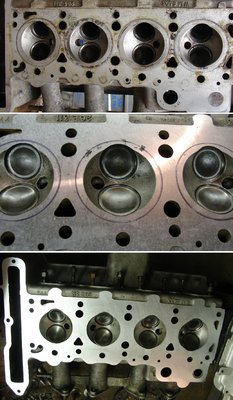

The head came back from being surfaced and I should have gone and done some work but it was 95F yesterday and the same again today. I really didn't want to go and pick it up and sit in traffic for an hour and a half each way with Beauregard looking at me panting. I got a set of rear calipers put together at home and while thats a little on the light side of things that needed to be done, it's still progress. Today I hope to get 2 pair of front calipers assembled and maybe some other stuff. I don't think I have ever set a goal or a date. With the way I get things done, the only date thats important is the last one that has yet to be determined so I just need to use them all to the best advantage till there gone

Gary

------------------

June 21st 12:00pm

I did up the two pair of front calipers that I had blasted and painted several weeks ago. That is I installed the stainless caliper pistons and new seals. I was set to use the new caliper dust seal retaining spring rings but I couldn't get them to hold the the dust seal in a manor that I figured would be effective. Take a look at the nice shiny ring on the left.

the retaining ring seems to pinch at one end and lift the dust seal so that water can get in and rust the piston to the outer portion of the caliper piston bore that is just under the dust seal. I had both together and tried 3 or 4 times before I said to myself that I guess the old dust seal retaining rings were going to get reused. NEVER toss anything is a good way to work when doing this stuff, you just never know what you get with todays replacement parts. I found both sets of rings and cleaned them up with the wire wheel. I had two vintages from the disassembly, one set looked like square section and the other looked more like a flattened round stock. This was not what I wanted but I didn't want the stuff to fail in a years time either so I put the old parts in. The Ring on the right is one of the Square section ones and it holds the dust shield nicely.

side by side of the new on the left and the old on the right.

The second set of fronts with the "flattened round" springs installed and ready to bolt back together.

Thursday June 21st 5:15pm

I was about 95 degrees so I wasn't doing much and I looked out on the front porch and there was a care package sitting there. I opened it up and said to myself "I guess I know what I am doing tomorrow".

Well I figured I could do a little bit to get a jump on things so I cut some plywood to rough out a lid for the RHD glove box and traced out the LHD lid to make a pattern. Got out the skill saw and trimmed it close to the lines

and then worked it on the belt sanded for a bit. seems the fiberglass has moved a bit over the years and my template is the reverse of the original LHD lid and its a bit short in height on the left side so 1 prototype done and I'll get back to this when I get a new belt for the belt sander, it a bit used up and I think its time.

Friday June 22nd 08:8:15am

Started to put all the parts I could think of together this morning. first task was to cut off the column mount tab for the LHD column. That took about 5 seconds. several clamps to hold things in position and a bit of masking tape to hold the lovely crashpad in shape. Its going to take a lot of work to get this very far away from the sows ear that it is now. Tough to even squint and see it as an Elan. I do love to see the finished product but we seem to miss out on a lot of good photos by some. The metamorphoses on many Elans is just so dramatic that you would never know that they are indeed the same. I think its a truly forward thinking person with vision that will show their Elan with the before, during and after photos. Me, I just don't care what some think and I really want to motivate people to get on with their own projects as there are no Elans beyond reclamation unless fire (or some dpo) has had its way.

Anyhow I marked the location of the mounting holes and now I need to pull it apart and see what and where they are. I don't like the gap between the dashboard and glove box so I think that I'll be making at least one possibly 2 more dashes before I like what I am seeing. Still not sure about crashpads, I think I'll have to pull off the vinyl from this thing of beauty and recover it. This project does not warrant one of the type 26 reproductions that are being offered now.

pretty close but

Seems like this is the reason for the next pattern, sure glad I have the glove box now it will solidify things and maybe I'll get the next one closer.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

The mail man came today and dropped off a package. A "new shifter" that my friend Phil sent me. It needs some work but doesn't everything. I got the base cleaned up and noticed that it had a number 105 E 7305 or 105 E 7505 on the shifter base.

The shift handle is a bit long and bent but thats fine. Phil put an extra bend in it so it fit in the box, I told him the length I needed and he adjusted it to that length.

when done it will look like these two that were done previously.

Monday June 25th 4pm

Yes it was a slow day, rain this morning and it cleared and now its pouring out again, I almost forgot, I'll get the base painted up with the Hunter green and black mix that I have been using...

The morning started off nice and clouded over quickly, I had the cover off of Tingles C prod body and put the dash back in and the glove box too. I got out pencil and some masking tape and used the cut off tab that held the LHD steering column that I had cut off as a guide (it was laying in the body shell still, remember never toss anything out ) and marked the dash with the pencil. I took it out and used the worn out belt on the belt sander to nose into the crotch and a small block to sand straight the line next to the glove box and reinstalled. Pulled both dash and glove box together and had a nice uniform gap of about an 1/8 inch. I found the quart of Minwax polyurethane that I had around forever and shook the can and it seemed like liquid so I opened and stirred it a bit and poured some into the spray gun and laid the dash out on the 4 x 8 painting plywood and gave it a few passes and then brought it inside before the rain and thunderstorm passed through. Got the body covered up and called it. I need to get some part put in and place it back in the body to see if it is something that I can live with but it may be just about close to use as it is (if I squint hard)

) and marked the dash with the pencil. I took it out and used the worn out belt on the belt sander to nose into the crotch and a small block to sand straight the line next to the glove box and reinstalled. Pulled both dash and glove box together and had a nice uniform gap of about an 1/8 inch. I found the quart of Minwax polyurethane that I had around forever and shook the can and it seemed like liquid so I opened and stirred it a bit and poured some into the spray gun and laid the dash out on the 4 x 8 painting plywood and gave it a few passes and then brought it inside before the rain and thunderstorm passed through. Got the body covered up and called it. I need to get some part put in and place it back in the body to see if it is something that I can live with but it may be just about close to use as it is (if I squint hard)  .

.

both prototypes, urethaned on the left, original right

Tuesday June 26th 7:15pm

Very little done today, unsettled weather with rain threatening all day. It finally came down about 3pm. I was looking at the first reject dash while I was making coffee this morning and pulled out the boiled linseed oil and gave it a coat to see how the walnut looked, I let soak in and wiped off the excess after I had coffee. the sun was out so I sanded the urethane on the second dash and took that out for another coat and brought it in to dry. About 10am I looked at the first proto dash and I like the color but knew it would never hold up in a roadster, I gave it another wipe down with BLO and let it sit till noon. It was dry to the touch but it should have sat over night but I was impatient so I brought it out and gave it a coat of Urethane just to see how the two product would react. Lover the color and I need to play around some more with this method and see how it will hold up. May have to leave it outside and subject it to some of the daily thunderstorms after I urethane the back.

both prototypes, first proto with Boiled linseed oil and urethaned on the left, second proto just urethaned right

While waiting for things to dry I got the shifter out and thought I would see if I could get enough heat into it with a propane torch to straighten it. I managed to get a dull cherry red and put it in the vice and took a lot of the bend out. I also manged to make it sine wave shape so a lot more heating and some additional pressure in the vice and finally got out my favorite tool (3 pound hammer) and heated and hit until the strait edge looked consistent. I cut off the right angle bend that Phil put in it to ship and cleaned it up a bit. I hope to get more done tomorrow

Straightened shifter - top, and one of the finished shifters - bottom

Thursday June 28th 5:00am

I went to fetch my head that's been surfaced for nearly a couple of weeks and it looks a whole lot better. I guess I need to get off my ass and get on with it now.

I brought a couple of shifters with me and got the end of one trimmed up and got some threads put on so it wouldn't hurt so much to use the shifter (without the jam nut). Bill and I trimmed a second one that I butchered 20 years ago. We put tab A onto one part to fit into slot B in the other and I'll get Karl to put some glue on it to make it all better.

Picked up two sets of front wheel bearings at the bearing supply house in Quincy so I am good for a while. Need some front rotors now, I priced them and they have gone up too so I will think about those for a bit before I bite the bullet.

Saturday 30th of June 4:00am

It was starting to get warm out yesterday so I painted the shifters early and went inside to shim the head. Had some problems with the cosworth style shims that I had access to. I had bought a bunch from Don Tingle when the doors closed at TLC and they had a deeper recess for the tip of the valve than the ones that were installed in the head. So when I did the valve shim math it was not working. It took me a few passes with the intake to figure what the hell I was doing wrong as you can see from the picture of the shifters on the shim math scribbles. The intakes just weren't cooperating and it was until I started to measure the total height of cosworth shim that I figured it out. The recessed pockets for the valve stem in the shims in my head were like .060 inch while the new ones I had were .100 so the shims were bottoming on the valve keepers and not the top of the valve stem. once I figured that out the valve shim math started to work again...

The two piece shifter in the photo above is not the third painted shifter in the photo, thats has yet to be welded.

First of July 06:55

I needed some black gauges to make the S1 style dash look right and I wasn't going to use those that I had from the LoCort so what was I to do? I thought about it and I had some bezels that were not being used so I sandblasted the chrome off and put a coat of semi-gloss black on them. Turns out I distorted them blasting them and it was an absolute bitch to get them back together. I took off some of the semi-gloss on two of them trying to re-install so after comparing them to the original black bezel gauges, they sere too shiny so I stripped them again and flat-blacked them and I think they came out a bit nicer looking. I still had problems assembling one of them so I taped off the gauge that was giving me real problems after I had the bezel installed and painted it. this is the result and I think it will be just fine for the sow's ear that it is. I wish I had a good crashpad to use but I don't so that may be one of the next low dollar projects to do. If it looks like crap then I'll shit can crashpad and leave it off and flat black the area.

The shift handle is a bit long and bent but thats fine. Phil put an extra bend in it so it fit in the box, I told him the length I needed and he adjusted it to that length.

when done it will look like these two that were done previously.

Monday June 25th 4pm

Yes it was a slow day, rain this morning and it cleared and now its pouring out again, I almost forgot, I'll get the base painted up with the Hunter green and black mix that I have been using...

The morning started off nice and clouded over quickly, I had the cover off of Tingles C prod body and put the dash back in and the glove box too. I got out pencil and some masking tape and used the cut off tab that held the LHD steering column that I had cut off as a guide (it was laying in the body shell still, remember never toss anything out

both prototypes, urethaned on the left, original right

Tuesday June 26th 7:15pm

Very little done today, unsettled weather with rain threatening all day. It finally came down about 3pm. I was looking at the first reject dash while I was making coffee this morning and pulled out the boiled linseed oil and gave it a coat to see how the walnut looked, I let soak in and wiped off the excess after I had coffee. the sun was out so I sanded the urethane on the second dash and took that out for another coat and brought it in to dry. About 10am I looked at the first proto dash and I like the color but knew it would never hold up in a roadster, I gave it another wipe down with BLO and let it sit till noon. It was dry to the touch but it should have sat over night but I was impatient so I brought it out and gave it a coat of Urethane just to see how the two product would react. Lover the color and I need to play around some more with this method and see how it will hold up. May have to leave it outside and subject it to some of the daily thunderstorms after I urethane the back.

both prototypes, first proto with Boiled linseed oil and urethaned on the left, second proto just urethaned right

While waiting for things to dry I got the shifter out and thought I would see if I could get enough heat into it with a propane torch to straighten it. I managed to get a dull cherry red and put it in the vice and took a lot of the bend out. I also manged to make it sine wave shape so a lot more heating and some additional pressure in the vice and finally got out my favorite tool (3 pound hammer) and heated and hit until the strait edge looked consistent. I cut off the right angle bend that Phil put in it to ship and cleaned it up a bit. I hope to get more done tomorrow

Straightened shifter - top, and one of the finished shifters - bottom

Thursday June 28th 5:00am

I went to fetch my head that's been surfaced for nearly a couple of weeks and it looks a whole lot better. I guess I need to get off my ass and get on with it now.

I brought a couple of shifters with me and got the end of one trimmed up and got some threads put on so it wouldn't hurt so much to use the shifter (without the jam nut). Bill and I trimmed a second one that I butchered 20 years ago. We put tab A onto one part to fit into slot B in the other and I'll get Karl to put some glue on it to make it all better.

Picked up two sets of front wheel bearings at the bearing supply house in Quincy so I am good for a while. Need some front rotors now, I priced them and they have gone up too so I will think about those for a bit before I bite the bullet.

Saturday 30th of June 4:00am

It was starting to get warm out yesterday so I painted the shifters early and went inside to shim the head. Had some problems with the cosworth style shims that I had access to. I had bought a bunch from Don Tingle when the doors closed at TLC and they had a deeper recess for the tip of the valve than the ones that were installed in the head. So when I did the valve shim math it was not working. It took me a few passes with the intake to figure what the hell I was doing wrong as you can see from the picture of the shifters on the shim math scribbles. The intakes just weren't cooperating and it was until I started to measure the total height of cosworth shim that I figured it out. The recessed pockets for the valve stem in the shims in my head were like .060 inch while the new ones I had were .100 so the shims were bottoming on the valve keepers and not the top of the valve stem. once I figured that out the valve shim math started to work again...

The two piece shifter in the photo above is not the third painted shifter in the photo, thats has yet to be welded.

First of July 06:55

I needed some black gauges to make the S1 style dash look right and I wasn't going to use those that I had from the LoCort so what was I to do? I thought about it and I had some bezels that were not being used so I sandblasted the chrome off and put a coat of semi-gloss black on them. Turns out I distorted them blasting them and it was an absolute bitch to get them back together. I took off some of the semi-gloss on two of them trying to re-install so after comparing them to the original black bezel gauges, they sere too shiny so I stripped them again and flat-blacked them and I think they came out a bit nicer looking. I still had problems assembling one of them so I taped off the gauge that was giving me real problems after I had the bezel installed and painted it. this is the result and I think it will be just fine for the sow's ear that it is. I wish I had a good crashpad to use but I don't so that may be one of the next low dollar projects to do. If it looks like crap then I'll shit can crashpad and leave it off and flat black the area.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

THe weather has been warm since last week so I thought it would be a good idea to get back to the body work. I picked up some bondo and a tube of polyester glazing putty last Thursday. Over the weekend it was in the 90's and well I just do get things done in those kind of temperatures so I waited as long as I could to jump back into doing body work. Its been over 4 years since I played around with Tingles C production body.

elan-f14/tingles-production-race-elan-body-t16586-15.html

It does not look like a lot and it certainly was not and probably won't ever be. Charles sold me it for $100 and a friend needed a headlamp bucket so he gave me $60. My net cost was $40, I did a lot of work to get it to where it was when I moved it to it's new work area on Monday. I haven't touched the body but on Tuesday I started to work a bit on the doors and the front and rear bumpers just to ease into it. For Independence day I went over to Russ's to take a look at his Elite project and didn't do a thing at home so I got started again this morning Sanding off the polyester glazing putty that I put on the doors and rear bumper Tuesday and repeated the process a couple of times. Things were close so I found the primer that was 4 years old, maybe a bit older (probably closer to 6). I opened it and it looked ok and it stirred into something that I thought I could spray. I put it through a paint filter and mixed the 2 parts and went out and sprayed the doors first, then the bumpers. I got one coat one and things went to shit fast. I had just about finished and the gun stopped spraying and it was still heavy so I opened the lid and saw jelly and quickly dumped it out. The fire drill started and went through a quart of acetone cleaning out the gun. The epa would have had a fit, the cloud of acetone and K38 primer was drifting across the road and the traffic seemed to be slowing down but no one stopped . I guess I'll do a smaller batch next time.

. I guess I'll do a smaller batch next time.

Gary

Friday, July sixth 8:45am

I got a fairly early start to beat the heat. After the pictures were taken yesterday afternoon, the prime had hardened I looked for the obvious defects and suck-ins and skimmed those that I saw with polyester glazing putty. I put them away and went out to the Lighthouse for the Thursday evening car show.

The first thing I did was to wet sand off the putty and prime to get it back to being flattened to look at, then washed off all of the sanding scum and left in the sun to dry while I did the next part. So far I have done both bumpers and one door. The sun had dried those parts so I looked at them pretty closely with my bad eyes and saw what I had missed.

Before I prime again I want to fill in as many of those problem areas as possible to minimize the number of steps needed to get a decent looking paint job.

I need to sand this again as well as the two bumpers. I have not even sanded the second door so that will get the same treatment. I'll get another coat of prime on everything latter today. I should be using a guide coat but I am not all that fussy with this particular job as its not that kind of a project. I am just looking for a 20 foot paint job and if I get something close or better I'll be happy.

Gary

elan-f14/tingles-production-race-elan-body-t16586-15.html

It does not look like a lot and it certainly was not and probably won't ever be. Charles sold me it for $100 and a friend needed a headlamp bucket so he gave me $60. My net cost was $40, I did a lot of work to get it to where it was when I moved it to it's new work area on Monday. I haven't touched the body but on Tuesday I started to work a bit on the doors and the front and rear bumpers just to ease into it. For Independence day I went over to Russ's to take a look at his Elite project and didn't do a thing at home so I got started again this morning Sanding off the polyester glazing putty that I put on the doors and rear bumper Tuesday and repeated the process a couple of times. Things were close so I found the primer that was 4 years old, maybe a bit older (probably closer to 6). I opened it and it looked ok and it stirred into something that I thought I could spray. I put it through a paint filter and mixed the 2 parts and went out and sprayed the doors first, then the bumpers. I got one coat one and things went to shit fast. I had just about finished and the gun stopped spraying and it was still heavy so I opened the lid and saw jelly and quickly dumped it out. The fire drill started and went through a quart of acetone cleaning out the gun. The epa would have had a fit, the cloud of acetone and K38 primer was drifting across the road and the traffic seemed to be slowing down but no one stopped

Gary

Friday, July sixth 8:45am

I got a fairly early start to beat the heat. After the pictures were taken yesterday afternoon, the prime had hardened I looked for the obvious defects and suck-ins and skimmed those that I saw with polyester glazing putty. I put them away and went out to the Lighthouse for the Thursday evening car show.

The first thing I did was to wet sand off the putty and prime to get it back to being flattened to look at, then washed off all of the sanding scum and left in the sun to dry while I did the next part. So far I have done both bumpers and one door. The sun had dried those parts so I looked at them pretty closely with my bad eyes and saw what I had missed.

Before I prime again I want to fill in as many of those problem areas as possible to minimize the number of steps needed to get a decent looking paint job.

I need to sand this again as well as the two bumpers. I have not even sanded the second door so that will get the same treatment. I'll get another coat of prime on everything latter today. I should be using a guide coat but I am not all that fussy with this particular job as its not that kind of a project. I am just looking for a 20 foot paint job and if I get something close or better I'll be happy.

Gary

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

Not getting a lot done but having some fun. Money has not been spent, its hot so I have been doing a bit of body work and paint exploration. I didn't like the Rustoleum Gloss Black so I painted over it with the Hunter Green with 15% gloss black and I think its in the running, I like green and I have a couple Elans painted green, one BRG and the other Brooklands green. It looks pretty good except for a few bubbles but I am new to this and its painted out in the driveway so not any sort of ideal conditions.

It has a decent shine, this combo was 120 grams hunter green 18 grams of Gloss Black and 25% acetone and I think its getting close to the right percentage to apply.

Just because I would like to do another color I looked into Medici Blue. I looked up the colors in Georges formula with ppg tints

elan-f14/early-and-early-coupe-colors-t16387.html

DCM937 is Blue Shade Phthalo Green

DCM904 is Red Shade Phthalo Blue

DMC901 is Strong Black

DMC900 is Strong White

Shit, I had some hunter green and gloss Black, all I needed was some blue and white so I went off to Lowes and picked up a quart of each for $20. I tried to mix to the formula but it looked like hell. So it was eyeball time, I found the bonnet still had a good bit of Medici Blue left along the edges, it is pretty well faded out so I am just guessing but I think I came kind of close. The second batch I made by eyeball was 20 grams of Royal Blue and 5 grams of Gloss White and 3 grams of Hunter green. Its a bit darker than the sample area that I wet sanded with 1500 wet paper but once I wet it down with some water it looks damn close to my eye.

The inset square is from the lip of the bonnet and just wet sanded with 1500 wet/dry paper done with water, the slide area is done the same way but to get a better idea of the true color of the old paint I wet it down and took the photo. I need to do a larger batch and paint a panel just to get a better idea of what it will look like. the run on the right is 20 grams of Royal Blue with 3 grams of white and 2 grams of green (I think), I kept adding till it looked pretty close one gram at a time.

It has a decent shine, this combo was 120 grams hunter green 18 grams of Gloss Black and 25% acetone and I think its getting close to the right percentage to apply.

Just because I would like to do another color I looked into Medici Blue. I looked up the colors in Georges formula with ppg tints

elan-f14/early-and-early-coupe-colors-t16387.html

DCM937 is Blue Shade Phthalo Green

DCM904 is Red Shade Phthalo Blue

DMC901 is Strong Black

DMC900 is Strong White

Shit, I had some hunter green and gloss Black, all I needed was some blue and white so I went off to Lowes and picked up a quart of each for $20. I tried to mix to the formula but it looked like hell. So it was eyeball time, I found the bonnet still had a good bit of Medici Blue left along the edges, it is pretty well faded out so I am just guessing but I think I came kind of close. The second batch I made by eyeball was 20 grams of Royal Blue and 5 grams of Gloss White and 3 grams of Hunter green. Its a bit darker than the sample area that I wet sanded with 1500 wet paper but once I wet it down with some water it looks damn close to my eye.

The inset square is from the lip of the bonnet and just wet sanded with 1500 wet/dry paper done with water, the slide area is done the same way but to get a better idea of the true color of the old paint I wet it down and took the photo. I need to do a larger batch and paint a panel just to get a better idea of what it will look like. the run on the right is 20 grams of Royal Blue with 3 grams of white and 2 grams of green (I think), I kept adding till it looked pretty close one gram at a time.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

crannyr wrote:Great post,

I have sent you a PM

Rick

Hi Rick

It was great to see you and thanks again for the Diff housing, it will greatly improve the sow's ear status as an Elan. Good to see another Elan getting brought back to be driven on the street too. I am sure your daughter will enjoy the hours as much as you will, learning - teaching how to "bring it back from the dead". A couple of pictures from yesterday.

Oh and do try and get that 64 Miata out for a spin too

elan-photos-f18/racer-t14383.html

Oh yea, heres one more just to keep on topic, the shocks are just what I was looking for too, Straightened out the bent sway bar lug and hope to get them sandblasted today...

9:50 am

A better look at the shocks and they are plus2, Oh well I got the alloy differential with the torsen assembled with new seals, shafts in place and put in the chassis. I even tightened some bolts that seemed like they a bitch with more stuff in the way like the brake pipes and the 3 and 5 way junctions that the pipes feed into.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

piss-ant wrote:For Independence day I went over to Russ's to take a look at his Elite project and didn't do a thing at home

Gary - To say you took a look at my Elite project is a bit of an understatement. We worked out paint and filler removing technique using a heat gun and a wood chisel. Time to shop for Elite body sections! Thanks for your perspiration on a muggy day!

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1545

- Joined: 09 Nov 2006

Gary,

Happy to see you gathered a good rear-end housing. Should work out much better for the build.

You and Russ had a good days work removing all the bondo! Russ should get a new section and seam it back in place.

So Russ what year is your LOG picture and location?

Mark

Happy to see you gathered a good rear-end housing. Should work out much better for the build.

You and Russ had a good days work removing all the bondo! Russ should get a new section and seam it back in place.

So Russ what year is your LOG picture and location?

Mark

-

memini55 - Third Gear

- Posts: 345

- Joined: 09 Jan 2004

memini55 wrote:So Russ what year is your LOG picture and location?

This question confused me for a bit until I realized the Log 14 photo is visible on my garage wall. This was the Elite celebration at Lime Rock Park in Connecticut. My yellow +2S is in the middle of the front row. Not too many Elitists were happy about being pushed over to the right side for the photograph although I recall there was also a separate photo for Elites only.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1545

- Joined: 09 Nov 2006

Total Online:

Users browsing this forum: No registered users and 1 guest