differential brace

20 posts

• Page 1 of 2 • 1, 2

I'm about to change the differential in my S4 SE from a whining 3.77:1 (I think) to a rebuilt 3.54:1 from an escort RS2000, which is close to the original Lotus 3.55:1 that it should have. Whilst I'm at it I would like to fit a differential brace, as used on the sprint - does anybody have a spare one of these for sale (preferably UK), or can anyone point me at a (dimensioned) drawing so I can make one?

Any other hot tips on changing diffs whilst I'm down there?

Thanks

Kevin

Any other hot tips on changing diffs whilst I'm down there?

Thanks

Kevin

- enskr

- First Gear

- Posts: 44

- Joined: 28 Jan 2004

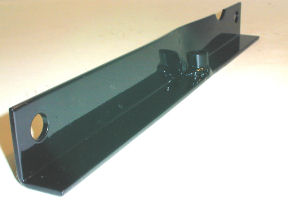

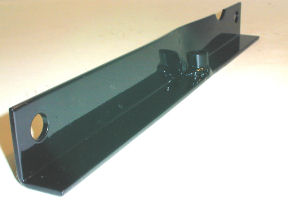

There is a diagram in the files section of elan.net mailing list, I have attached a pic incase you cannot access it and you might want to read this thread

http://www.lotuselan.net/forums/viewtopic.php?t=1609

http://www.lotuselan.net/forums/viewtopic.php?t=1609

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3407

- Joined: 11 Sep 2003

$65 fron Ray at RD Enterprises

http://www.rdent.com

Differential Stiffening Bracket

Introduced by Lotus on the Elan Sprint, this part can be installed on any Elan or Plus 2. The brace connects the two differential mounting bolts and picks up one bolt on the differential housing, strengthening the overall assembly to prevent damage to the differential mounting "ears." Highly recommended for any Elan or Plus 2, whether equipped with rotoflex couplings or c-v rear axles.

Ref. 36R0033 $65.00

http://www.rdent.com

Differential Stiffening Bracket

Introduced by Lotus on the Elan Sprint, this part can be installed on any Elan or Plus 2. The brace connects the two differential mounting bolts and picks up one bolt on the differential housing, strengthening the overall assembly to prevent damage to the differential mounting "ears." Highly recommended for any Elan or Plus 2, whether equipped with rotoflex couplings or c-v rear axles.

Ref. 36R0033 $65.00

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

TTR list the brace at ?20 + VAT. Hardly worth the effort in trying to make one.

You can fit the brace only with the diff in situ, and you will need a bolt about 20mm longer than the existing one.

My experience when reassembling recently was that I could not get the longer bolt into the tube due to it fouling the chassis. I cut a slot in the tube, partly engaged the bolt which enabled the brace to be slid into place.

Don?t forget to fit both large washers to the Frustacone mounts.

You can fit the brace only with the diff in situ, and you will need a bolt about 20mm longer than the existing one.

My experience when reassembling recently was that I could not get the longer bolt into the tube due to it fouling the chassis. I cut a slot in the tube, partly engaged the bolt which enabled the brace to be slid into place.

Don?t forget to fit both large washers to the Frustacone mounts.

Brian Clarke

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

(1972 Sprint 5 EFI)

Growing old is mandatory..........Growing up is optional

-

bcmc33 - Coveted Fifth Gear

- Posts: 1708

- Joined: 10 Apr 2006

Brian said: "Hardly worth the effort in trying to make one."

On a monetary basis, I agree. But ... there is satisfaction to be had.

If you have rudimentary welding skills and modest equipment, then it is a fairly easy project. And you have the satisfaction of seeing the product of your own hand.

Much of the reason we own Elans is to work on them ourselves. I view the construction of a differential brace as a continuation of this spirit.

I made one for my Elan (used the plans above:Sprint_Diff_Bracket_V2.jpg). It came out pretty nice. It was easy. It was fun. It was satisfying. But it was not economically sound (Brian is right).

Rich Boyd

On a monetary basis, I agree. But ... there is satisfaction to be had.

If you have rudimentary welding skills and modest equipment, then it is a fairly easy project. And you have the satisfaction of seeing the product of your own hand.

Much of the reason we own Elans is to work on them ourselves. I view the construction of a differential brace as a continuation of this spirit.

I made one for my Elan (used the plans above:Sprint_Diff_Bracket_V2.jpg). It came out pretty nice. It was easy. It was fun. It was satisfying. But it was not economically sound (Brian is right).

Rich Boyd

-

richboyd - Second Gear

- Posts: 77

- Joined: 12 Sep 2003

billwill wrote:Where does this fit ???

On top of the differential, between the "ears" and the Lotocone mounts through which the mounting bolts pass. Looking at the photo posted earlier, mentally rotate the bracket 90 degrees toward you - then the holes are on top. The mounting bolts pass through these holes. The long replacement bolt goes through the bushing in the brace, which is now horizontal. It's a tight fit.

Andrew Bodge

'66 Elan S2 26/4869

I love the sound of a torque wrench in the morning. Sounds like... progress.

'66 Elan S2 26/4869

I love the sound of a torque wrench in the morning. Sounds like... progress.

-

RotoFlexible - Fourth Gear

- Posts: 622

- Joined: 01 Sep 2005

bcmc33 wrote:and you will need a bolt about 20mm longer than the existing one.

I was thinking about getting a brace for my S1 - but I have noticed that my workshop manual shows that the the two halves of the differential casing are allegedly held together by studs and not bolts.

I'm now too past-it to get under the car to have look, so can anyone confirm that studs were used on the S1?

Getting a stud out of the casing and replacing it with a longer stud is probably impossible without removing the diff - unless someone knows better.

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

Mine has bolts. It is the early type casting (with the non-script "Lotus" lettering). I have no evidence that it was ever taken apart (I'm pretty sure the bearings were original when I got to it) but can't say for certain.

Paddy

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1036

- Joined: 27 Oct 2008

Or Maybe fabricate one

like this...elan-f14/diff-stiffening-bracket-extra-strong-design-t23499.html

like this...elan-f14/diff-stiffening-bracket-extra-strong-design-t23499.html

Live your dream-wear your passion.

http://elantrikbits.com/lotus-elan-blog/

http://elantrikbits.com/lotus-elan-blog/

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

AlfaLofa wrote:bcmc33 wrote:and you will need a bolt about 20mm longer than the existing one.

I was thinking about getting a brace for my S1 - but I have noticed that my workshop manual shows that the the two halves of the differential casing are allegedly held together by studs and not bolts.

I'm now too past-it to get under the car to have look, so can anyone confirm that studs were used on the S1?

Getting a stud out of the casing and replacing it with a longer stud is probably impossible without removing the diff - unless someone knows better.

Definately virtually impossible even with a Spyder chassis which has a cut out. Not enough purchase on a small ring spanner and believe me I tried! I ended up fitting the brace but without the Diff bolt - which partially defeats the object - I'll have to wait until one day when i need to remove the diff to do the job properly...

- 106500

- Second Gear

- Posts: 51

- Joined: 18 Feb 2004

Just installed one within the last couple of weeks. It was a pain to get that "center" , lateral bolt which goes into the rear cover of the diff. I tried with it tight and getting the diff. in place was a pain. Bad shoulder so I didn't bother with the usual many minutes of tussling. Instead I loosened that bolt and was able to more easily (still a little tricky) get that diff. in place.

Bolt heads at bottom , nuts up top.

I also installed a small marine type port as others have done , for ease of access to the diff. for filling.

Bolt heads at bottom , nuts up top.

I also installed a small marine type port as others have done , for ease of access to the diff. for filling.

Cheers!

- SubaruPaul

- First Gear

- Posts: 48

- Joined: 28 Apr 2011

20 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: promotor and 8 guests

.jpg)